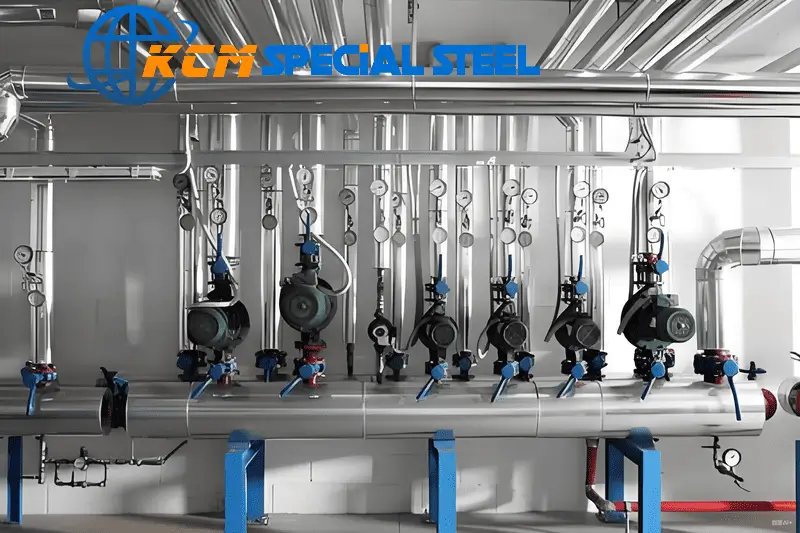

316L stainless steel pipe is widely employed across chemical processing, marine engineering, food production, and energy sectors due to its enhanced corrosion resistance—primarily attributed to the addition of 2–3% molybdenum. However, its performance is highly dependent on specific environmental conditions, including acid concentration, chloride content, temperature, pressure, and flow dynamics. Misapplication—especially in mid-concentration sulfuric acid or high-temperature supercritical CO₂ systems—can lead to rapid failure. This article provides a comprehensive, data-driven analysis of 316L’s behavior in three critical corrosive environments: acidic media, seawater/chloride-rich settings, and high-temperature/high-pressure conditions. Practical mitigation strategies, repair protocols, and material selection guidelines are also presented, supported by verified corrosion rate tables and real-world case insights.

28

Nov