Description

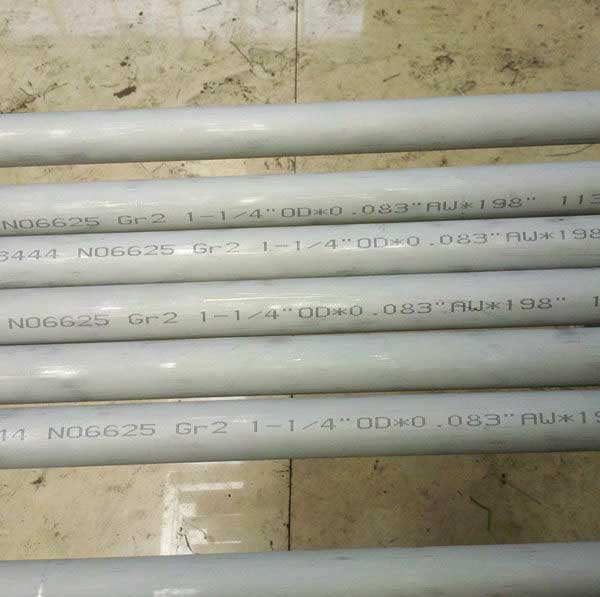

Nickel Alloy Inconel 625 Pipes & Fittings

Nickel Alloy Inconel 625 Pipes & Fittings has excellent corrosion resistance and oxidation resistance, from low temperature to 980 ℃ have good tensile properties and fatigue properties, and salt stress corrosion under the atmosphere. Therefore, it can be widely used in the manufacture of aircraft engine parts, aerospace structural components and chemical equipment and contact with sea water and bear high mechanical stress occasions.

Nickel Alloy Inconel 625 Pipes Corresponding grades at home and abroad:

| Alloy | CHINA GB | USA UNS | GERMANY SEW VDIUV | UK BS | FRANCE AFNOR |

| Inconel 625 | NS3306 | N06625 | W.Nr.2.4856 NiCr22Mo9Nb | NA21 | NC 22 DNb |

Nickel Alloy Inconel 625 Supply Specifications:

Round bar, bar, sheet, pipe, seat, spheres, flanges and forgings

Nickel Alloy Inconel 625 Pipes & Fittings Chemical composition:

| Alloy | C | Mn | Si | P | S | Cr | Ni | Mo | Ti | Al | Fe | Others |

| Inconel 625 | ≤0.10 | ≤0.50 | ≤0.50 | ≤0.015 | ≤0.015 | 20.0 ~23.0 | 54.0 ~60.0 | 8.0 ~10.0 | ≤0.40 | ≤0.40 | ≤5.0 | Nb 3.15~4.15 |

Nickel Alloy Inconel 625 Pipes & Fittings Physical properties:

| Density | 8.4g/cm3 |

| Melting Point | 1290-1350℃ |

Nickel Alloy Inconel 625 Pipes & Fittings Minimum mechanical properties of alloys at room temperature:

| Alloy and state | Tensile strength Rm N/mm2 | Yield Strength RP0.2N/mm2 | Elongation A5 % | Brinell Hardness HB |

| 625 | 760 | 345 | 30 | ≤220 |

Nickel Alloy Inconel 625 Pipes & Fittings has the following features:

1. The corrosion and reduction of the environment of the various corrosive media have a very good anti-corrosion ability

2. Excellent resistance to pitting and crevice corrosion, and does not produce stress corrosion cracking due to chloride

3. Excellent resistance to inorganic acid corrosion, such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid and sulfuric acid and hydrochloric acid mixed acid

4. Excellent resistance to various inorganic acid mixed solution corrosion

5. Temperature of 40 ℃, in a variety of concentrations of hydrochloric acid solution can show a good corrosion resistance

6. Good machinability and weldability, solderless cracking resistance

7. Manufacturing certification of pressure vessel with wall temperature of -196 ~ 450 ℃

8. Certified by the American Society of Corrosion Engineers NACE (MR-01-75) Highest Standard Grade VII for Acid Gas Environments

Inconel 625 metallographic structure:

Alloy 625 is a face-centered cubic lattice structure. When the temperature is about 650 ° C for a sufficient period of time, the carbon particles and the unstable quaternary phase are precipitated and converted into a stable Ni3 (Nb, Ti) orthorhombic lattice phase. The molybdenum and niobium components in the nickel-chromium matrix after solid solution strengthening will improve the mechanical properties of the material, but the plasticity will be reduced.

Nickel Alloy Inconel 625 Pipes & Fittings corrosion resistance:

Nickel Alloy Inconel 625 Pipes & Fittings in many media have shown excellent corrosion resistance. Has excellent resistance to pitting, crevice corrosion, intergranular corrosion and erosion in chloride media.

It Has a good resistance to inorganic acid corrosion, such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid, etc., while in the oxidation and reduction environment also has alkali and organic acid corrosion performance. Effective resistance to chloride ion reduction stress corrosion cracking.

In the seawater and industrial gas environment almost no corrosion, the sea water and salt solution has a high corrosion resistance, the same is true at high temperatures. There is no sensitivity in the welding process. In a static or recycling environment are resistant to carbonation and oxidation, and resistance to chlorine-containing gas corrosion.

Nickel Alloy Inconel 625 Pipes & Fittings process performance and requirements:

Thermal processing

1. Hot processing temperature range 1150 ℃ ~ 900 ℃, cooling method for water quenching or other rapid cooling.

2. For optimum performance and corrosion resistance, annealing is performed after hot working.

3. Heating, the material can be directly into the temperature has been the highest temperature of the furnace, the insulation for a sufficient time (100mm thickness required 60 minutes holding time) quickly baked in the specified temperature range of high temperature processing. When the material temperature falls below the hot working temperature, need to reheat.

Nickel Alloy Inconel 625 Pipes & Fittings Cold working

1. Cold processing material should be annealed, the processing hardening rate than austenitic chrome-nickel stainless steel.

2. Cold work, the need for intermediate annealing.

3. When the processing capacity is greater than 15%, the thermal processing to be followed by annealing.

Nickel Alloy Inconel 625 welding process

1. Suitable for welding with any conventional welding process.

2. The material to be welded should be solid solution, remove the scale, oil and a variety of markings.

3. Heat treatment is no longer required before and after welding.

Nickel Alloy Inconel 625 Pipes & Fittings Applications Applications are:

Softened annealed low-carbon Nickel Alloy Inconel 625 Pipes & Fittingswidely used in the chemical process industry, better corrosion resistance and high strength so that it can be used as thin structural parts. Nickel Alloy Inconel 625 Pipes & Fittingscan be used in contact with sea water and withstand high mechanical stress occasions. Typical application areas:

1. A component of an organic chemical process process containing chloride, especially in the case of an acidic chloride catalyst

2. A digester and bleach tank for the pulp and paper industry

3. Absorption tower in flue gas desulfurization system, reheater, flue gas inlet baffle, fan (wet), stirrer, baffle and flue

4. Used in the manufacture of equipment and components for use in acidic gas atmospheres

5. Acetic acid and acetic anhydride reaction generator

6. Sulfuric acid condenser