20

Jun

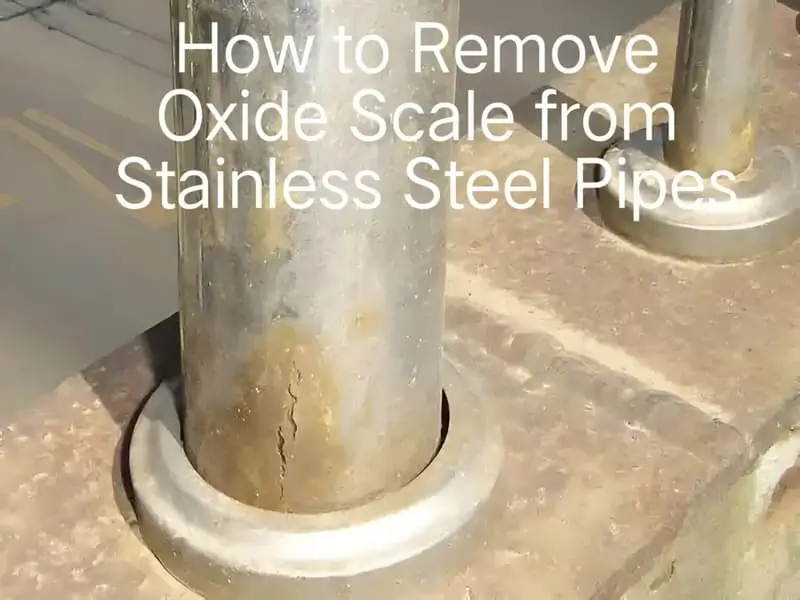

1. Introduction to Duplex Stainless Steel Pipes in Marine Environments The welding of duplex stainless steel pipe in offshore platforms is The specialized fusion joining process, using qualified procedures and matching/compatible filler metals, applied to...