- Home

- Products

- STAINLESS STEEL PIPE AND FITTINGS

- Stainless Steel Pipe Suppliers T4 Tube

- STAINLESS STEEL PIPE FITTINGS

- 304 Stainless Steel Pipe

- 304L Stainless Steel Pipe

- 321 Stainless Steel Pipe

- 316 Stainless Steel Tubing Pipe

- 316L Stainless Steel Pipe

- 316Ti Stainless Steel Pipe

- 317L Stainless Steel Pipe

- TP347H STAINLESS STEEL PIPE

- 310 / 310S Stainless Steel Pipe Suppliers

- 904L Stainless Steel Pipe

- 253MA Stainless Steel Pipe UNS S30815 1.4835

- Stainless Steel Square Tube

- AL-6XN Stainless Steel Pipe UNS N08367 1.4529

- 254SMO Stainless Steel Pipe UNS S31254 1.4547

- DUPLEX STAINLESS STEEL PIPE AND FITTINGS

- Duplex 2205 Stainless Steel Pipe

- SUPER DUPLEX 2507 STAINLESS STEEL PIPE

- Astm A790 / A789 UNS S31803 Duplex Pipe Tube

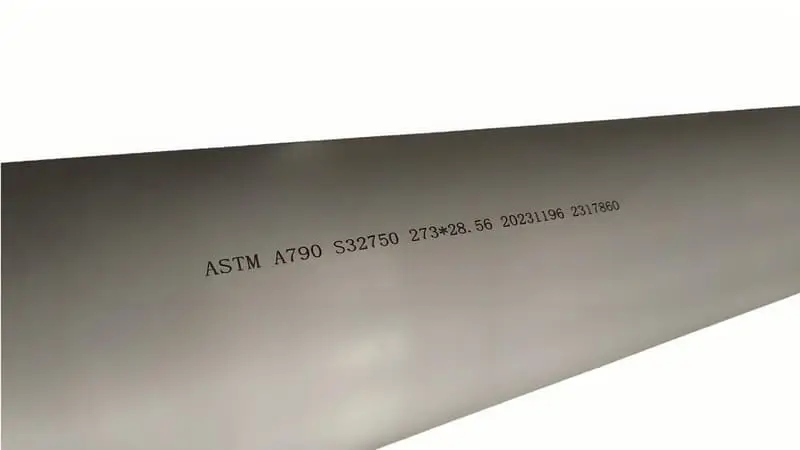

- ASTM A790 UNS S32750 Super Duplex Pipe/Tube

- ASTM A815 UNS S31803 Duplex Steel Pipe Fittings / S32205 Butt Weld Fittings / SAF 2205 Duplex Pipe Fittings

- ASTM A928 UNS S31803 EFW Pipe / SA928 S32205 Welded Duplex Pipes

- ASTM A928 UNS S32750 EFW Super Duplex Pipe / 2507 Welded Pipe 1.4410

- ASTM A815 UNS S32750 Super Duplex Steel Pipe Fittings / 2507 1.4410 F53

- Duplex 2304 Stainless Steel Pipe

- Duplex S32760 Stainless Steel Pipe

- NICKEL ALLOY PIPE AND FITTINGS

- Nickel Alloy Hastelloy C-276 Pipe and Fittings UNS N10276 2.4819

- Alloy 200/Nickel 200 Pipe and Fittings UNS N02200 2.4066

- Alloy 201/Nickel 201 Pipe and Fittings UNS N02201 2.4068

- Nickel Alloy Monel 400 Pipes And Fittings

- Nickel Alloy Inconel 600 Pipes And Fittings

- Nickel Alloy Inconel 601 Pipes And Fittings

- Nickel Alloy Inconel 625 Pipes And Fittings

- Nickel Alloy Inconel 718 Pipes And Fittings

- Nickel Alloy Incoloy 800H Pipes And Fittings

- Nickel Alloy INCOLOY 800HT Pipes and Fittings

- Nickel Alloy Incoloy 825 Pipes And Fittings

- ASTM A453 Grade 660 A/B/C/D Stainless Steel: Plate, Sheet, Bar, Rod, Forgings

- STAINLESS STEEL PIPE FLANGES

- STAINLESS STEEL VALVES

- CARBON STEEL PIPE AND FITTINGS

- STAINLESS STEEL PIPE AND FITTINGS

- STANDARDS

- STAINLESS STEEL STORE

- ABOUT

- CONTACT

industry news

26

May

Duplex Stainless Steel Pipe/Tubes/Tubing for Chemical Industrial Applications Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical IndustryDuplex stainless steel pipes (DSS pipes), tubes, and tubing have become indispensable in the chemical industry due to...

23

May

Transverse Cracking in 304 Stainless Steel Seamless Pipe Unlock Transverse Cracking in 304 Stainless Steel Seamless Pipe,Why Does 304 Stainless Steel Seamless Pipe Transverse Cracking Occur? and How to Solve 304 Stainless Steel Seamless Pipe...

19

May

WHY SUPER DUPLEX 2507/S32750 PIPE CORROSION RESISTANCE HIGH PERFORMANCE? Introduction to Super Duplex 2507/S32750 PipesSuper Duplex 2507 (UNS S32750) is a premium-grade stainless steel alloy that offers exceptional corrosion resistance combined with high mechanical strength....

17

May

This study investigates chloride-induced pitting corrosion in 304L stainless steel pipes (ASTM A312/A358 TP304L) through metallurgical analysis and industry case studies. The research identifies critical thresholds for chloride concentration (>100 ppm) and temperature (>50°C) that accelerate pit formation in 304L stainless steel pipe systems. Microscopy and SEM-EDS analyses reveal characteristic 0.1-0.3mm surface pits with subsurface wedge-shaped cavities (1.2-2.8mm depth), accompanied by chromium depletion (>70% reduction). The 304L stainless steel pipe pitting corrosion analysis demonstrates material limitations including low PREN (18.7) and CPT (<50°C in 3.5% NaCl). Comparative testing confirms electropolishing (Ra <0.25µm) and upgraded alloys (316L/2205 duplex) improve resistance. Standardized mitigation protocols are proposed, incorporating ASTM G48 testing, 1100°C post-weld heat treatment, and quarterly eddy current inspections. The findings provide actionable guidelines for extending service life of ASTM A312 TP304L stainless steel pipes in chloride-rich environments while maintaining cost-efficiency.

09

May

Nickel Alloy Pipe Supplier in China / ISO Certified Manufacturer: KCM Special Steel Co., Ltd KCM Special Steel Co., Ltd is a leading supplier and ISO-certified manufacturer of premium nickel alloy pipes in China. Renowned...

07

May

UNS S32205/2205 Duplex Seamless Pipe Creep Strength: A Comprehensive Analysis AbstractUNS S32205/2205 duplex seamless pipe creep strength exhibit exceptional creep resistance (≤300°C) due to their balanced austenite-ferrite microstructure and optimized Cr/Ni/Mo/N chemistry. These pipes deliver...

05

May

Austenitic stainless steel, renowned for its exceptional corrosion resistance, high-temperature stability, and superior mechanical properties, is extensively utilized across industries such as chemical processing, petrochemicals, nuclear energy, aerospace, and healthcare. However, its performance hinges on the integrity of its passive oxide layer. This article explores the necessity of pickling and passivation processes in optimizing stainless steel’s corrosion resistance, surface quality, and compliance with industrial standards. Technical mechanisms, practical applications, and comparative data are analyzed to underscore their indispensable role in engineering.

02

May

This study explores the microstructural changes, mechanical properties, and erosion-corrosion resistance of super duplex 2507 stainless steel pipes (UNS S32750, SAF2507) under varying heat treatment conditions. Through systematic experiments involving normalizing at 1050°C followed by single and double tempering within 500°C–700°C, the interplay between hardness, toughness, and anti-wear performance was rigorously analyzed. Results demonstrate that tempering at 550°C after normalizing delivers the optimal balance of mechanical and anti-corrosion properties, establishing it as the most cost-effective industrial process. The findings also address widespread public misconceptions about stainless steel, clarifying its compositional nuances and performance criteria.

30

Apr

316L stainless steel pipes (SS316L/TP316L) are low-carbon, molybdenum-enhanced austenitic alloys renowned for exceptional corrosion resistance in harsh environments. This article details their manufacturing processes, including hot rolling, cold drawing, and precision welding, alongside stringent quality control measures such as non-destructive testing (NDT) and compliance with ASTM/EN standards. Key applications span marine engineering, chemical processing, and architectural restoration, exemplified by their use in the Champs-Élysées fountain renovation. The alloy’s mechanical properties—tensile strength (485–620 MPa), density (8.0 g/cm³), and thermal stability (up to 870°C)—are analyzed, along with failure modes like chloride-induced cracking and preventive strategies such as passivation and material certification. Comparisons with carbon steel and 304 stainless steel highlight 316L’s superior durability despite higher costs. Maintenance protocols, including alkaline cleaning and biannual inspections, ensure decades of reliable service. This guide underscores the critical role of 316L stainless steel pipes in modern infrastructure, balancing technical rigor with practical insights for engineers and industry professionals.

Keywords: 316L stainless steel pipe, SS316L pipe, TP316L stainless steel pipe, corrosion resistance, ASTM standards.

23

Apr

Comparing 310 and 310S stainless steel pipes: 310 (≤0.25% C) offers superior high-temperature strength, suited for non-welded thermal environments (e.g., boilers); 310S (≤0.08% C) provides excellent weldability and cyclic heat stress resistance, with marginally higher cost but lower maintenance. A 1–2% density difference has minimal impact on most applications. Key uses: high-temperature structural components (310) vs. heat exchangers and welded systems (310S).