904L vs 310S Stainless Steel Pipe Introduction

904L and 310S stainless steel pipes are both lauded for corrosion and heat resistance, yet their divergent chemistries dictate specialized applications. While 310S excels in extreme heat, 904L dominates aggressive chemical environments. This analysis dissects their composition, performance limits, and industrial suitability through verified technical data.

What is Difference Between 904L and 310S Stainless Steel Pipe

904L (super-austenitic) excels in corrosive environments (e.g., acids, seawater) due to high Mo (4-5%) and Cu (1-2%), while 310S (high-temperature austenitic) prioritizes heat resistance (up to 1100°C) with higher Cr (24-26%) but lacks Mo. 904L suits chemical/ocean applications; 310S fits furnaces/exhausts. 904L costs more.

Material Composition and Corrosion Resistance

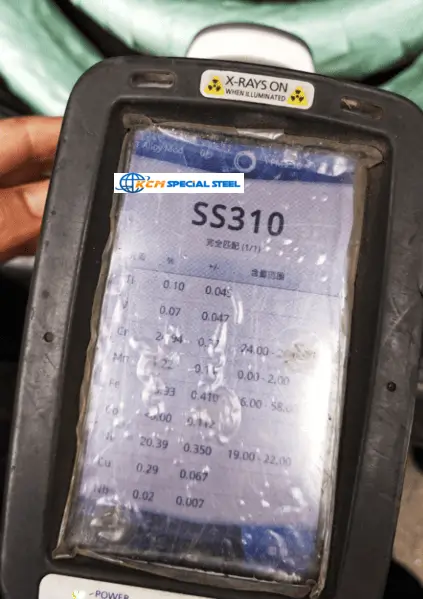

904L stainless steel is a super-austenitic alloy containing high levels of chromium (19-23%), nickel (23-28%), and molybdenum (4-5%), along with added copper (1-2%). This composition grants exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking, particularly in harsh environments like seawater or acidic conditions. In contrast, 310S stainless steel is a high-temperature austenitic alloy with higher chromium (24-26%) and nickel (19-22%) but negligible molybdenum (≤0.75%) and no copper. While 310S excels in oxidation resistance at temperatures up to 1100°C due to its chromium-rich oxide layer, it lacks 904L’s versatility in corrosive chemical or marine applications.

Applications and Mechanical Properties

904L pipes are widely used in chemical processing, offshore oil rigs, and desalination plants where corrosion resistance is critical. Their low carbon content (≤0.02%) minimizes carbide precipitation during welding, ensuring durability. However, 904L has lower tensile strength (490 MPa) compared to 310S (515 MPa). 310S pipes, with superior thermal stability, are ideal for furnace parts, heat exchangers, and exhaust systems. Their higher carbon content (≤0.08%) enhances creep resistance but reduces weldability without post-weld treatments. Cost-wise, 904L is pricier due to its premium alloying elements, while 310S offers a budget-friendly option for high-heat scenarios where corrosion is secondary.

1. Composition and Metallurgical Design-904L vs 310S Stainless Steel Pipe

904L vs 310S Stainless Steel Pipe

310S Stainless Steel Pipe

- Primary Alloys: 25% Cr, 20% Ni, ≤0.08% C (UNS S31008)

- Key Features:

- High chromium-nickel ratio enables robust oxidation resistance.

- Optimized carbon content sustains strength above 800°C.

ASTM A312 TP 904L Stainless Steel Pipe

- Primary Alloys: 20% Cr, 24% Ni, 4.3% Mo, 1.5% Cu, ≤0.02% C (UNS N08904)

- Key Features:

- Molybdenum-copper synergy enhances acid resistivity.

- Ultra-low carbon prevents carbide precipitation during welding.

Table 1: Chemical Composition Comparison (%)

| Element | 310S | 904L |

|---|---|---|

| Chromium | 25.0 | 20.0 |

| Nickel | 20.0 | 24.0 |

| Molybdenum | – | 4.3 |

| Copper | – | 1.5 |

| Carbon | ≤0.08 | ≤0.02 |

| Density | 7.98 g/cm³ | 8.24 g/cm³ |

2. Corrosion Resistance: Critical Divergences-904L vs 310S Stainless Steel Pipe

904L vs 310S Stainless Steel Pipe

310S Limitations:

- Vulnerable to sulfuric/phosphoric acids and chloride-induced pitting.

- Prone to carburization (>800°C) and nitridation in ammonia-rich environments, causing Cr₂₃C₆ precipitation and grain boundary embrittlement.

904L Advantages:

- Exceptional resistance to non-oxidizing acids:

- Handles 98% H₂SO₄ ≤40°C and 85% H₃PO₄ indefinitely.

- Superior chloride resistance:

- Withstands seawater/offshore conditions via Mo-Cu synergy.

- Critical Note: Fails in nitric acid or >2% HCl concentrations.

Table 2: Corrosion Performance in Key Media

| Environment | 310S | 904L |

|---|---|---|

| Sulfuric Acid | Poor | Excellent (≤40°C) |

| Seawater | Moderate pitting risk | Exceptional resistance |

| Phosphoric Acid | Moderate | Excellent (≤85%) |

| Nitric Acid | Good | Poor |

3. Thermal Stability and Mechanical Properties-904L vs 310S Stainless Steel Pipe

310S Stainless Steel Pipes Dominance in Heat:

- Operating Limits: Continuous use at 1150°C (peak 1200°C).

- Mechanism: Cr₂O₃ scale prevents oxidation but risks σ-phase embrittlement at 600–700°C.

904L Thermal Constraints:

- Max Service Temperature: 300°C long-term; rapid degradation above 400°C due to σ-phase formation.

Table 3: Mechanical Properties at Room Temperature

| Property | 310S | 904L |

|---|---|---|

| Tensile Strength | ≥520 MPa | ≥490 MPa |

| Yield Strength | ≥205 MPa | ≥220 MPa |

| Elongation | ≥40% | ≥35% |

| Hardness (HB) | ≤187 | ≤180 |

4. Industrial Application Suitability-904L vs 310S Stainless Steel Pipe

| Environment | Recommended Alloy | Rationale |

|---|---|---|

| Furnaces/Boilers (>800°C) | 310S | Unmatched thermal stability |

| Sulfuric Acid Reactors | 904L | Mo/Cu resist reducing acids |

| Offshore Platforms | 904L | Superior pitting/crevice resistance |

| Ammonia Processing | 310S | Withstands nitridation |

5. Fabrication and Economic Factors-904L vs 310S Stainless Steel Pipe

- 310S Advantages:

- Lower cost (~30% cheaper than 904L).

- Easier welding/machining with standard austenitic techniques.

- 904L Challenges:

- Requires ER385 filler to preserve corrosion resistance post-weld.

- Higher alloy cost due to Ni/Mo/Cu content.

Conclusion-904L vs. 310S Stainless Steel Pipe

310S stainless steel tubing remains the benchmark for extreme heat applications like industrial furnaces, leveraging its chromium-nickel stability up to 1200°C. Conversely, 904L stainless steel pipe/tube excels in corrosive chemical processing, where its molybdenum-copper matrix defeats acids and chlorides that ravage standard steels. While 904L offers broader corrosion resistance, its thermal limitations and cost preclude high-temperature substitution. Engineers must prioritize operational exposure—whether heat, acid, or chloride—to optimize performance and lifecycle economics.