What is S31254 Stainless Steel?

This article clarifies why S31254 is not duplex stainless steel, explores its true classification as a super austenitic stainless steel, compares it with genuine duplex grades, lists its common alternative designations, and explains the metallurgical rationale behind its categorization.

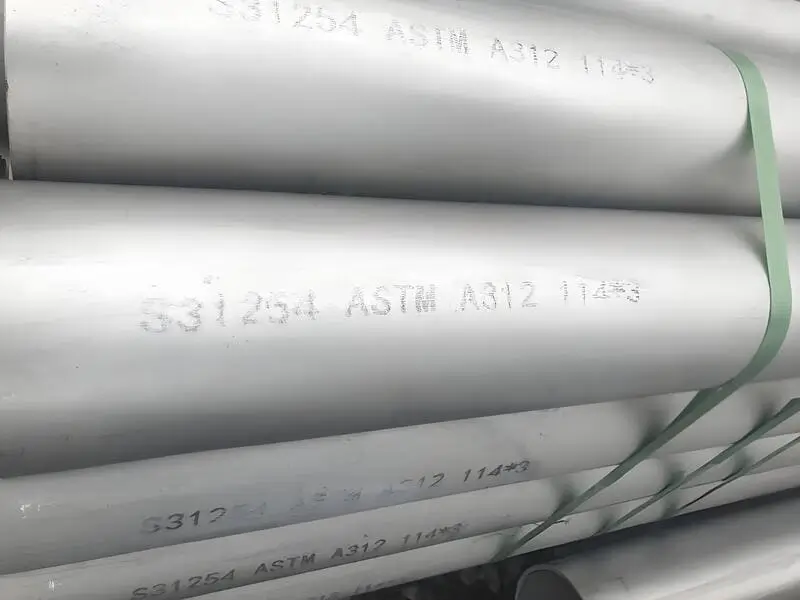

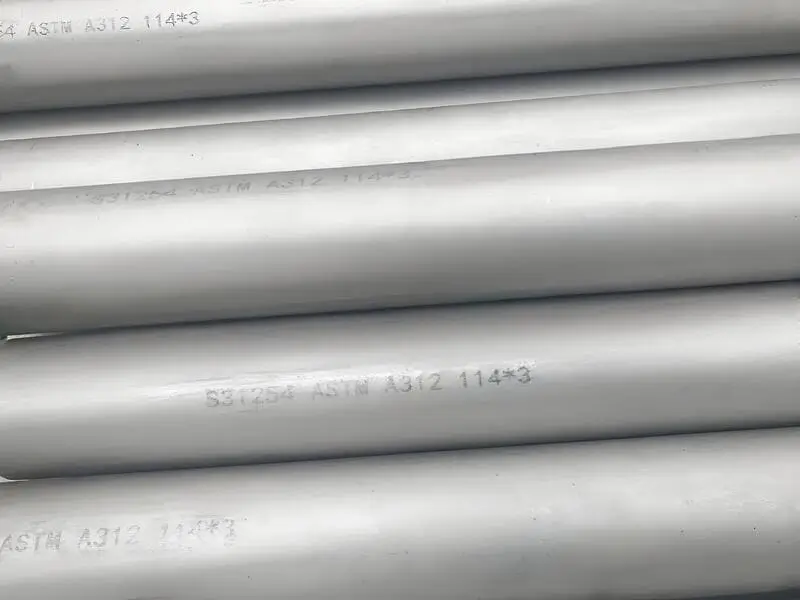

S31254 is a high-alloy austenitic stainless steel (UNS S31254, 6% Mo) with excellent corrosion resistance, especially in chloride environments, due to high chromium (20%), nickel (18%), and molybdenum (6.1%) content.Common equivalents: 254 SMO®, UNS S31254, 1.4547, X1CrNiMoCuN20-18-7.

Stainless steels are a cornerstone of modern engineering, offering a remarkable blend of corrosion resistance, mechanical strength, and fabricability. Among the various families—martensitic, ferritic, austenitic, and duplex—each serves distinct industrial needs based on composition, microstructure, and performance. One alloy that often sparks confusion is UNS S31254 (1.4547 / 254 SMO®). Despite its exceptional corrosion resistance—particularly in aggressive chloride environments—S31254 is frequently mistaken for a duplex stainless steel. However, this assumption is fundamentally incorrect.

1. Fundamental Microstructural Differences

Why S31254 Is Not Duplex Stainless Steel

The primary distinction between stainless steel families lies in their microstructure, which is dictated by chemical composition and processing history. Duplex stainless steels derive their name from their dual-phase structure: approximately 50% ferrite (α) and 50% austenite (γ). This balance provides high strength and good resistance to stress corrosion cracking (SCC), especially in chloride-rich environments.

In contrast, S31254 is a single-phase austenitic alloy. Its microstructure consists almost entirely of austenite, stabilized by high levels of nickel and nitrogen. There is no intentional formation of ferrite. As confirmed by metallographic analysis and phase diagrams (e.g., Schaeffler or DeLong diagrams), the composition of S31254 falls squarely within the austenitic field, with negligible ferrite content (<1–2%). This absence of a dual-phase structure immediately disqualifies it from being classified as duplex.

Key Point: If an alloy lacks a balanced mixture of ferrite and austenite, it cannot be duplex—regardless of how corrosion-resistant it may be.

2. Chemical Composition: The Decisive Factor

Why S31254 Is Not Duplex Stainless Steel

Chemical composition governs phase formation. Below is a comparative table highlighting the typical compositions of S31254 versus representative duplex grades (e.g., UNS S32205/S31803 and UNS S32750):

| Element (wt%) | UNS S31254 (Super Austenitic) | UNS S32205 (Standard Duplex) | UNS S32750 (Super Duplex) |

|---|---|---|---|

| Chromium (Cr) | 19.5–20.5 | 21.0–23.0 | 24.0–26.0 |

| Nickel (Ni) | 17.5–18.5 | 4.5–6.5 | 6.0–8.0 |

| Molybdenum (Mo) | 6.0–6.5 | 2.5–3.5 | 3.0–4.0 |

| Nitrogen (N) | 0.18–0.25 | 0.08–0.20 | 0.24–0.32 |

| Manganese (Mn) | ≤1.0 | ≤2.0 | ≤1.0 |

| Carbon (C) | ≤0.02 | ≤0.03 | ≤0.03 |

| Iron (Fe) | Balance | Balance | Balance |

| Ferrite Number (FN) | <2 | 30–50 | 30–50 |

Source: ASTM A240, EN 10088-2, NACE MR0175/ISO 15156

Several observations are critical:

- Nickel Content: S31254 contains nearly three times more nickel than standard duplex grades. Nickel is a potent austenite stabilizer; such high levels suppress ferrite formation entirely.

- Ferrite Number (FN): Measured via magnetic or metallographic methods, FN quantifies ferrite content. S31254 consistently shows FN < 2, well below the 30–50 range required for duplex classification.

- Molybdenum: While both S31254 and super duplex steels contain high Mo (for pitting resistance), the microstructural outcome differs due to Ni and Cr ratios.

Thus, despite sharing high Mo and N with super duplex grades, S31254’s chemistry is engineered to maintain a fully austenitic structure—not a mixed one.

3. Why Is S31254 Classified as a Super Austenitic Stainless Steel?

Why S31254 Is Not Duplex Stainless Steel

The term “super austenitic” refers to advanced austenitic stainless steels with:

- PREN (Pitting Resistance Equivalent Number) ≥ 40

- High Mo (≥6%), Cr (≥20%), and N (≥0.2%)

- Excellent resistance to localized corrosion (pitting, crevice)

The PREN is calculated as:

PREN = %Cr + 3.3×%Mo + 16×%N

For S31254:

PREN = 20 + (3.3 × 6.25) + (16 × 0.22) ≈ 20 + 20.6 + 3.5 = 44.1

This exceeds the 40 threshold, confirming its “super” status. Moreover:

- It retains excellent ductility and weldability—hallmarks of austenitic steels.

- It does not require post-weld heat treatment, unlike some duplex grades sensitive to improper cooling rates.

- Its density is approximately 8.0 g/cm³, consistent with austenitic alloys (ferrite is slightly less dense, but the difference is minor—within 1–2%, as noted in literature).

Therefore, S31254 belongs unequivocally to the super austenitic stainless steel family.

4. Performance Comparison: S31254 vs. Duplex Steels

Why S31254 Is Not Duplex Stainless Steel

While both types excel in corrosive environments, their behaviors diverge under specific conditions:

| Property | S31254 | Super Duplex (e.g., S32750) |

|---|---|---|

| Yield Strength (MPa) | ~300 | ~550 |

| Tensile Strength (MPa) | ~650 | ~750 |

| Elongation (%) | ≥40 | ≥25 |

| SCC Resistance (Chlorides) | Excellent | Excellent |

| Pitting Resistance (Critical Pitting Temp, °C in 6% FeCl₃) | ~70–80 | ~75–85 |

| Fabricability | Excellent (like 316L) | Moderate (requires control of heat input) |

| Magnetic Response | Non-magnetic | Slightly magnetic (due to ferrite) |

Note: Data based on typical mill test reports and NORSOK M-001 standards.

Why S31254 Is Not Duplex Stainless Steel

S31254 offers superior formability and toughness, making it ideal for complex fabrications (e.g., heat exchangers, flue gas desulfurization systems). Duplex steels, while stronger, are more prone to embrittlement if welded improperly and exhibit lower impact toughness at cryogenic temperatures.

5. Common Alternative Designations for S31254

Why S31254 Is Not Duplex Stainless Steel

S31254 is marketed under several trade and standard names globally. Recognizing these helps avoid specification errors:

| Standard System | Designation |

|---|---|

| UNS (Unified Numbering System) | S31254 |

| EN (European Norm) | 1.4547 |

| ASTM/ASME | Alloy 254, 254 SMO® |

| ISO | X1CrNiMoCuN20-18-7 |

| JIS (Japan) | SUS 31254 |

| GB (China) | 00Cr20Ni18Mo6CuN |

Despite naming differences, all refer to the same super austenitic composition.

6. Clarifying Misconceptions: Why the Confusion Exists?

Why S31254 Is Not Duplex Stainless Steel

Several factors contribute to the misclassification of S31254 as duplex:

- High Corrosion Resistance: Both super austenitics and super duplexes resist seawater and acidic chlorides, leading to functional overlap.

- Similar Alloying Elements: High Cr, Mo, and N are present in both, but their ratios and resulting phases differ.

- Marketing Terminology: Terms like “super” or “high-performance” are sometimes used loosely without clarifying microstructure.

Why S31254 Is Not Duplex Stainless Steel

However, performance similarity does not imply metallurgical identity. Just as titanium and Inconel® both resist corrosion but belong to different material classes, so too do S31254 and duplex steels.

7. Practical Implications of Misidentification

Why S31254 Is Not Duplex Stainless Steel

Using S31254 when a duplex is specified—or vice versa—can lead to:

- Overdesign: S31254 is significantly more expensive than standard duplex due to high Ni and Mo.

- Underperformance: In high-stress applications, S31254’s lower yield strength may be inadequate.

- Welding Issues: Assuming duplex welding procedures for S31254 could introduce unnecessary complexity.

Hence, accurate material identification is crucial for cost-efficiency and safety.

8. Why S31254 Is Not Duplex Stainless Steel Conclusion: Reaffirming the Classification

Why S31254 Is Not Duplex Stainless Steel

To directly answer the central question: Why is S31254 not duplex stainless steel?

- Microstructurally, it lacks the defining 50/50 ferrite-austenite mix; it is >98% austenite.

- Chemically, its high nickel content stabilizes austenite and suppresses ferrite formation.

- Metallurgically, it aligns with super austenitic criteria (PREN > 40, single-phase, non-magnetic).

- Standards-wise, ASTM, ISO, and EN all classify it as an austenitic grade.

Similarly, why UNS S31254 is not duplex steel and why 1.4547 is not duplex stainless steel stem from the same fundamental reasons: composition dictates structure, and structure defines category.

Why S31254 Is Not Duplex Stainless Steel

In summary, S31254 is a premium super austenitic stainless steel, engineered for extreme corrosion resistance where traditional austenitics (like 316L) fail—but it is not, and never was intended to be, a duplex alloy. Understanding this distinction ensures optimal material selection in demanding industries such as offshore oil & gas, chemical processing, and desalination.

Why S31254 Is Not Duplex Stainless Steel References (Illustrative – based on technical consensus):

- ASM Handbook, Vol. 1: Properties and Selection: Irons, Steels, and High-Performance Alloys

- NORSOK M-001: Materials Selection

- ASTM A240/A240M – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip

- ISO 15510: Stainless steels — Chemical composition