Dual certified 304/304L stainless steel meets the chemical composition requirements of both grades simultaneously. Crucially, its carbon (C) content is ≤0.030% (meeting 304L’s limit), while also satisfying all other mechanical properties and compositional requirements specified for 304. This allows interchangeable use, especially beneficial for welding where low carbon minimizes sensitization corrosion risk.

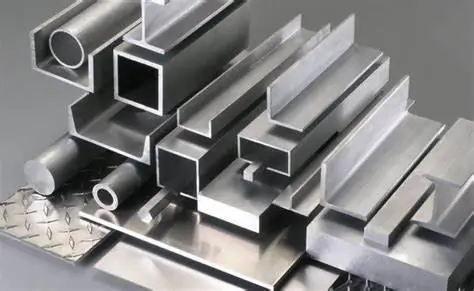

In industrial applications where corrosion resistance, weldability, and structural integrity are non-negotiable, dual certified 304/304L stainless steel emerges as a material of choice. Also interchangeably called dual grade 304/304L, this advanced alloy combines the optimal properties of both 304 and 304L stainless steels. Manufacturers like KCM SPECIAL STEEL (KCMSS) produce critical components—including pipes, fittings, flanges, bars, plates, sheets, and wires—in this versatile material for sectors ranging from pharmaceuticals to offshore engineering. This article explores its composition, advantages, global standards, and practical applications.

1. Defining Dual Certified 304/304L

Dual certified 304/304L stainless steel is a single material engineered to meet the chemical and mechanical requirements of both standard 304 (UNS S30400) and 304L (UNS S30403) grades. Unlike standard grades, it guarantees:

- Ultra-low carbon content (≤0.03%) of 304L for weld integrity.

- Enhanced tensile strength (≥515 MPa) matching 304-grade performance.

- Unified certification per ASTM A240/A480 and ASME SA-240.

Why “Dual Certified” Over “Dual Grade”?

While “dual grade 304/304L” is occasionally used colloquially, “dual certified” is the industry-recognized term. Certification requires rigorous third-party validation (e.g., mill test reports proving compliance with both specifications).

2. Chemical & Mechanical Properties

Table 1: Composition Comparison (Weight %)

| Element | 304 | 304L | Dual Certified 304/304L |

|---|---|---|---|

| Carbon (C) | ≤0.08% | ≤0.03% | ≤0.03% |

| Chromium (Cr) | 18.0–20.0% | 18.0–20.0% | 18.0–20.0% |

| Nickel (Ni) | 8.0–10.5% | 8.0–12.0% | 8.0–12.0% |

| Manganese (Mn) | ≤2.0% | ≤2.0% | ≤2.0% |

| Silicon (Si) | ≤0.75% | ≤0.75% | ≤0.75% |

Table 2: Mechanical Performance

| Property | 304 | 304L | Dual Certified 304/304L |

|---|---|---|---|

| Tensile Strength (MPa) | ≥515 | ≥485 | ≥515 |

| Yield Strength (MPa) | ≥205 | ≥170 | ≥205 |

| Elongation (% in 50mm) | ≥40 | ≥40 | ≥40 |

| Density (g/cm³) | 7.93 | 7.93 | 7.93 (1%-2% variance) |

| Hardness (Brinell) | ≤201 | ≤201 | ≤201 |

Note: Density remains consistent across grades but may vary by 1%-2% due to manufacturing tolerances.

3. Advantages of Dual Certification 304/304L Stainless Steel

a) Weldability Without Compromise

The low carbon content (≤0.03%) prevents carbide precipitation during welding. Consequently, dual certified stainless steel 304/304L eliminates “weld decay” (intergranular corrosion) without post-weld heat treatment.

b) Strength Retention

Unlike standalone 304L, dual certified material maintains 304-level tensile strength (≥515 MPa). This is critical for:

- Pressure vessels (ASME Section VIII compliance).

- Structural supports in corrosive environments.

c) Cost and Inventory Efficiency

Plants no longer need separate stocks for 304 and 304L. One dual certified batch serves both high-strength and high-weldability applications.

4. Manufacturing Standards & Certifications

Dual certified 304/304L must comply with:

- ASTM A240: Flat-rolled products.

- ASTM A312: Seamless/welded pipes.

- ASME SA-182: Flanges/fittings.

- EN 1.4301/1.4307: European equivalents.

Suppliers like KCM SPECIAL STEEL (KCMSS) provide mill test certificates (MTCs) validating dual compliance.

5. Key Applications of Dual Grade 304/304L Stainless Steel

Table 3: Industry-Specific Uses

| Industry | Components | Why Dual Certified? |

|---|---|---|

| Pharmaceuticals | Bioreactors, purification pipes | Resistance to sterilants (e.g., chlorine). |

| Food & Beverage | Fermentation tanks, conveyor systems | Non-contaminating, FDA-compliant surfaces. |

| Oil & Gas | Subsea valves, pipeline flanges | Withstands H₂S-induced stress corrosion. |

| Architecture | Coastal structural supports, facade cladding | Salt-air corrosion resistance. |

6. KCM SPECIAL STEEL’s Product Range for Dual Certified 304/304L Stainless Steels

KCM SPECIAL STEEL (KCMSS) delivers dual certified 304/304L stainless steel in these forms:

| Product Type | Specifications | Key Features |

|---|---|---|

| Pipes & Tubes | Size: 1/8″–60″ OD, SCH 5S–XXS | Seamless/welded, ASTM A312 compliant. |

| Fittings | Elbows, tees, reducers, cap, cross, stub end (ASME B16.9/ASTM A403) | CNC-machined, zero porosity. |

| Flanges | Slip-on, weld neck, Blind, Socket Weld, Thread, Lapp Joint (ASME B16.5/EN/GOST/DIN/JIS) | Pressure-rated up to 2500 PSI. |

| Bars & Rods | Round/flat/hex, ⌀5mm–500mm | Hot-rolled/cold-finished, ASTM A276. |

| Plates/Sheets | Thickness: 0.1mm–100mm, width: 1000–2000mm | 2B, BA, No. 4 finishes. |

| Wires | ⌀0.1mm–10mm, coils/cut lengths | ASTM A580, for springs/fasteners. |

7. Corrosion Resistance Data

Dual certified 304/304L excels in environments including:

- Acidic Solutions: ≤10% nitric acid at 20°C.

- Chloride Exposure: Up to 200 ppm (ambient temp).

- Pitting Resistance Equivalent (PRE): 19.5 (Cr + 3.3Mo + 16N).

Note: For higher chloride exposure (e.g., seawater), 316L is recommended.

8. Fabrication Best Practices

Machining

- Use sharp carbide tools.

- Maintain high cutting speeds.

- Employ coolant to prevent work hardening.

Welding

| Method | Filler Metal | Shielding Gas |

|---|---|---|

| TIG/GTAW | ER308L | 98% Ar + 2% N₂ |

| MIG/GMAW | ER308LSi | 90% He + 7.5% Ar + 2.5% CO₂ |

9. Sustainability & Recyclability

Like all austenitic stainless steels, dual certified 304/304L is 100% recyclable. KCMSS employs electric arc furnaces (EAFs) with >90% recycled scrap content, reducing carbon footprint by 70% vs. primary production.

10. Global Supply Chain Insights

Demand for stainless steel 304/304L surged by 12% annually (2020–2024), driven by:

- Chemical processing expansions in Asia-Pacific.

- Renewable energy infrastructure (hydrogen electrolyzers).

KCMSS supplies globally with lead times of 1–6 weeks for mill products.

Conclusion

Dual certified 304/304L stainless steel represents a pinnacle of materials engineering—delivering the weldability of 304L and the strength of 304 in one optimized alloy. For engineers specifying components exposed to corrosive media or cyclic stresses, this material eliminates compromise. Manufacturers like KCM SPECIAL STEEL (KCMSS) ensure ready availability of certified pipes, fittings, flanges, bars, plates, sheets, and wires, backed by traceable compliance documentation. As industries increasingly prioritize lifecycle cost over initial price, dual certified grades stand poised to dominate critical applications worldwide.