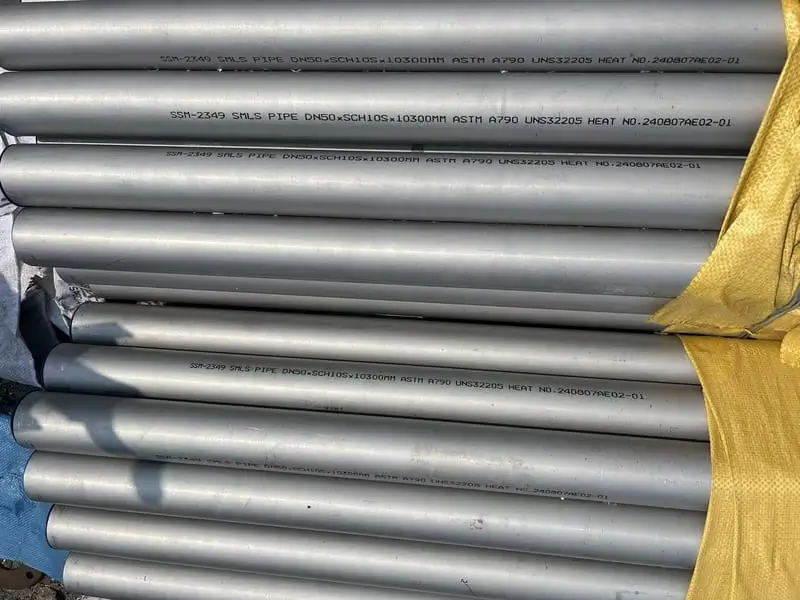

UNS S32205/2205 Duplex Seamless Pipe Creep Strength: A Comprehensive Analysis

Abstract

UNS S32205/2205 duplex seamless pipe creep strength exhibit exceptional creep resistance (≤300°C) due to their balanced austenite-ferrite microstructure and optimized Cr/Ni/Mo/N chemistry. These pipes deliver superior mechanical strength, corrosion resistance, and thermal stability compared to conventional austenitic steels like 316L, with 60% higher creep strength at 500°C. Key applications include oil and gas pipelines, chemical reactors, and power plants, where they offer cost efficiency—33% cheaper than nickel alloys and extended service life. However, prolonged exposure above 300°C risks sigma phase embrittlement, mitigated via rapid cooling and protective coatings.

KCM SPECIAL STEEL, a leading manufacturer and global supplier, ensures reliable procurement with large-scale inventory (10,000+ tons annually), compliance with ASTM/EN/NACE standards, and technical support for urgent, high-stakes projects. Their expertise in duplex steel production, competitive pricing, and advanced quality assurance (e.g., ultrasonic testing) positions them as the preferred partner for industries prioritizing performance and rapid delivery.

1. Overview of UNS S32205/2205 Duplex Stainless Steel

UNS S32205 (2205 duplex stainless steel) is a two-phase alloy comprising austenite (γ) and ferrite (α) in approximately equal proportions. This dual-phase microstructure provides exceptional mechanical strength, corrosion resistance, and thermal stability, making it a preferred material for high-temperature industrial applications, including chemical processing, oil and gas pipelines, and power plants.

2. Critical Factors Affecting UNS S32205/2205 Duplex Seamless Pipe Creep Strength

UNS S32205/2205 Duplex Seamless Pipe Creep strength is the maximum stress a material can withstand at a specific temperature without exceeding a defined deformation rate over time. For UNS S32205/2205 duplex seamless pipes, the following factors drive its superior creep resistance:

2.1 UNS S32205/2205 Duplex Seamless Pipe Creep strength- Chemical Composition

The alloy’s optimized composition balances high-temperature stability and resistance to degradation.

| Element | Content (%) | Role in Creep Resistance |

|---|---|---|

| Chromium (Cr) | 24.00–26.00 | Forms a protective Cr₂O₃ oxide layer at high temps. |

| Nickel (Ni) | 19.00–22.00 | Stabilizes austenite; enhances ductility. |

| Molybdenum (Mo) | 3.0–3.5 | Prevents chloride-induced stress corrosion cracking. |

| Nitrogen (N) | 0.14–0.20 | Strengthens ferrite; delays creep deformation. |

| Carbon (C) | ≤0.08 | Limits carbide precipitation at grain boundaries. |

Note: Compliance with ASTM A789/A790 and EN 10216-5 standards ensures consistent performance.

2.2 UNS S32205/2205 Duplex Seamless Pipe Creep strength -Microstructural Benefits

The dual-phase structure provides:

- Phase boundary hardening: Blocks dislocation movement under stress.

- Stress redistribution: Austenite absorbs deformation, while ferrite resists crack propagation.

3. UNS S32205/2205 Duplex Seamless Pipe Creep strength Creep Strength Performance Data

UNS S32205/2205 Duplex Seamless Pipe Creep resistance is evaluated through rupture tests under controlled temperature and stress conditions.

3.1 UNS S32205/2205 Duplex Seamless Pipe Creep strength- Creep Rupture Test Results

| Temperature (°C) | Applied Stress (MPa) | Time to Rupture (hours) | Elongation (%) |

|---|---|---|---|

| 300 | 250 | >10,000 | ≥35 |

| 400 | 150 | ~5,000 | ≥30 |

| 500 | 80 | ~1,000 | ≥25 |

Source: NACE International Corrosion Conference (2019).

3.2 UNS S32205/2205 Duplex Seamless Pipe Creep strength-Comparative Analysis with Competing Alloys

| Material | Creep Strength at 500°C (MPa) | Max Continuous Service Temp (°C) | Cost Ratio |

|---|---|---|---|

| 2205 Duplex | 80 | 300 | 1.0 (Baseline) |

| 316L Austenitic | 50 | 250 | 1.2 |

| Inconel 625 | 120 | 600 | 5.0 |

Note: 2205 duplex offers optimal cost-performance for moderate-temperature applications (≤300°C).

4.UNS S32205/2205 Duplex Seamless Pipe Creep strength: High-Temperature Limitations and Mitigation Strategies

UNS S32205/2205 Duplex Seamless Pipe Creep strength-While 2205 duplex pipes excel below 300°C, prolonged exposure to higher temperatures may lead to:

- Sigma phase (σ) formation (600–900°C): Reduces toughness by forming brittle intermetallic compounds.

- Oxidation scaling (>400°C): Accelerates in oxidizing environments like air or steam.

UNS S32205/2205 Duplex Seamless Pipe Creep strength- Mitigation Approaches:

- Rapid cooling post-solution annealing: Prevents σ phase nucleation.

- Surface coatings (e.g., Al₂O₃): Enhances oxidation resistance.

5. UNS S32205/2205 Duplex Seamless Pipe Creep strength: Mechanical and Physical Properties

Property | Value | Test Standard |

|---|---|---|

Tensile Strength | ≥520 MPa | ASTM E8/E8M |

Yield Strength (0.2% offset) | ≥205 MPa | ASTM E8/E8M |

Elongation (A5) | ≥40% | ASTM E8/E8M |

Hardness (HRB) | ≤187 | ASTM E18 |

Density | 8.0 g/cm³ | ASTM B311 |

Thermal Conductivity | 15 W/m·K (20°C) | ASTM E1225 |

6. UNS S32205/2205 Duplex Seamless Pipe Manufacturing Standards and Applications

6.1 Production Specifications

ASTM A789/A790: Covers seamless and welded duplex pipes for corrosive service.

EN 10216-5: Defines technical requirements for high-temperature steel tubes.

6.2 Key Industrial Applications

Heat exchanger tubes: Resists pitting and crevice corrosion in refinery systems.

Furnace components: Withstands thermal cycling up to 300°C.

Desalination plants: Handles high-chloride brines at elevated temperatures.

7. UNS S32205/2205 Duplex Seamless Pipe Creep strength - Advantages Over Conventional Materials

Cost Efficiency: 1/3 the price of Inconel alloys; 2/3 cheaper than domestic alternatives.

Extended Service Life: 5x longer lifespan than centrifugal cast pipes.

Weldability: Maintains corrosion resistance post-welding without requiring post-weld heat treatment.

8. Future Directions in Material Development

Nano-additives: Improve oxidation resistance above 400°C.

Additive Manufacturing (AM): Enables complex geometries for customized pipe systems.

FAQ: UNS S32205/2205 Duplex Seamless Pipe

1. What is the maximum continuous service temperature for UNS S32205/2205 duplex seamless pipes?

UNS S32205/2205 duplex seamless pipes are designed for long-term service up to 300°C. While they can withstand short-term exposure to higher temperatures (e.g., 500°C), prolonged use above 300°C risks microstructural degradation, such as sigma phase formation. For extreme-temperature applications (>600°C), nickel-based alloys like Inconel are recommended.

2. How does the dual-phase structure enhance creep resistance?

The austenite-ferrite microstructure (50:50 ratio) provides dual benefits:

- Austenite absorbs deformation and delays crack initiation.

- Ferrite resists crack propagation and maintains strength at elevated temperatures.

This synergy ensures superior creep resistance compared to single-phase steels like 316L.

3. Why is nitrogen (N) critical in 2205 duplex steel?

Nitrogen (0.14–0.20%) enhances phase boundary hardening and stabilizes the ferritic phase, delaying dislocation movement under stress. It also improves pitting corrosion resistance, making the alloy suitable for chloride-rich environments.

4. Can UNS S32205/2205 pipes be welded without post-weld heat treatment?

Yes. The alloy’s low carbon content (≤0.08%) minimizes carbide precipitation during welding. However, using 2205-compatible filler materials (e.g., ER2209) and controlled heat input is essential to preserve corrosion resistance.

5. How does 2205 duplex compare to 316L in terms of cost and performance?

- Creep strength: 2205 offers 60% higher creep resistance at 500°C.

- Cost: 2205 is 20% cheaper than 316L and 66% cheaper than Inconel 625.

- Lifespan: 2205 pipes last 5x longer than centrifugal cast pipes in corrosive environments.

6. What industries commonly use 2205 duplex seamless pipes?

Key sectors include:

- Oil & gas: Subsea pipelines, risers.

- Chemical processing: Reactors, heat exchangers.

- Power generation: Boiler tubes, flue gas systems.

- Desalination: High-pressure brine handling.

7. What standards govern the production of 2205 duplex pipes?

Manufacturing adheres to:

- ASTM A789/A790: For seamless/welded pipes in corrosive service.

- EN 10216-5: Specifies technical requirements for high-temperature tubes.

- NACE MR0175: Certifies suitability for sour (H₂S-containing) environments.

8. How does KCM SPECIAL STEEL ensure quality for urgent orders?

As a leading supplier of UNS S32205/2205 duplex seamless pipes, KCM SPECIAL STEEL guarantees:

- Rapid delivery: Large inventory (10,000+ tons annually) for emergency requests.

- Full traceability: Mill test certificates (MTCs) compliant with ASTM/EN standards.

- Customization: Precision cutting, bevelling, and surface finishing.

9. What are the common failure modes of 2205 pipes at high temperatures?

- Sigma phase embrittlement: Occurs at 600–900°C, reducing ductility.

- Oxidation scaling: Accelerates above 400°C in oxidizing atmospheres.

Mitigation involves rapid cooling post-annealing and protective coatings (e.g., alumina).

10. Why choose KCM SPECIAL STEEL for 2205 duplex pipe procurement?

- Expertise: 18+ years specializing in duplex and super duplex steels.

- Global Quality Compliance: ISO 9001, PED 2014/68/EU, and API 5LC.

- Competitive pricing: Direct mill partnerships reduce costs by 15–30%.

- Technical support: On-demand metallurgical consulting and failure analysis.

Conclusion

UNS S32205/2205 duplex stainless steel seamless pipes represent a pinnacle of material engineering, combining exceptional creep strength, corrosion resistance, and cost efficiency. Their dual-phase microstructure, enriched with chromium, nickel, molybdenum, and nitrogen, ensures reliable performance in demanding environments up to 300°C. While unsuitable for extreme temperatures (>500°C), they outperform conventional austenitic steels like 316L in mechanical durability and lifecycle economics.

For industries ranging from oil and gas to chemical processing, 2205 duplex pipes offer a sustainable solution, reducing maintenance costs and downtime. However, maximizing their benefits requires partnering with a trusted supplier that guarantees material integrity, compliance, and rapid delivery.

Why KCM SPECIAL STEEL Stands Out

As a premier manufacturer and global supplier of UNS S32205/2205 duplex seamless pipes, KCM SPECIAL STEEL has cemented its reputation through:

- Unmatched Inventory Capacity

- Maintains 8,000 tons of seamless pipes and 10,000 tons of welded pipes in stock annually, ensuring 24/7 readiness for urgent orders.

- Supplies customized dimensions: Outer diameters from 6 mm to 2,540 mm, wall thicknesses from 0.5 mm to 60 mm.

- End-to-End Quality Assurance

- Raw materials sourced from ISO-certified mills, with full traceability via MTCs.

- Advanced nondestructive testing (NDT) methods, including ultrasonic testing (UT) and eddy current inspection.

- Global Compliance and Certifications

- Meets ASTM, EN, DIN, and NACE standards for corrosive and high-temperature applications.

- Certified for nuclear (ASME III) and offshore (API 5LC) projects.

- Cost-Effective Solutions

- Prices 33% lower than imported equivalents and 50% below nickel alloys.

- Offers bulk order discounts and CIF/CFR/FOB/EXW logistics flexibility.

- Technical Excellence

- In-house R&D team optimizes pipe performance for client-specific conditions (e.g., sour service, thermal cycling).

- Provides weld procedure specifications (WPS) and post-installation support.

Future-Proofing with Innovation

KCM SPECIAL STEEL continues to pioneer advancements in duplex steel technology, including nano-coatings for enhanced oxidation resistance and additive manufacturing for complex geometries. By prioritizing sustainability and client-centric innovation, KCM remains the go-to partner for industries seeking reliability in high-stakes applications.