SCHEDULE 40 STAINLESS STEEL PIPE DIMENSIONS

SCHEDULE 40 STAINLESS STEEL PIPE DIMENSIONS,KCM SPECIAL STEEL HAS HONORED ONE OF THE LARGEST STAINLESS STEEL PIPE SUPPLIERS,MANUFACTURERS IN CHINA,ALL RANGE STAINLESS STEEL PIPES SEAMLESS AND WELDED ARE OFFERING AMZING PRICE AND GOOD QUALITY.

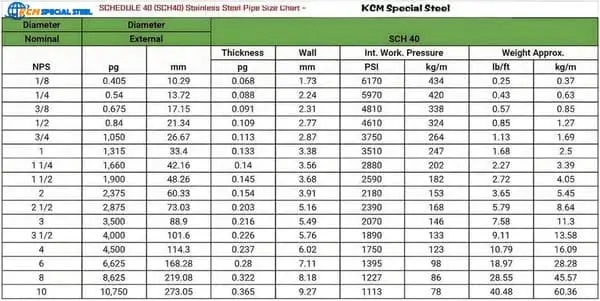

ADDITIONALLY, THE FOLLOWING IS AVAILABLE STANDARD SIZES OF READY STOCK OR ARRANGE PRODUCTION:(TABLE)

MEANWHILE,SCHEDULE 40 STAINLESS STEEL PIPE DIMENSIONS, KCM SPECIAL STEEL , IS ALSO OFFERING NON-STANDARD STAINLESS STEEL PIPE,ANY INQUIRY,PLS CONTACT US. https://www.duplexstainlesssteelpipes.com/

How to Find Schedule 40 Stainless Steel Pipe Wall Thickness (2025 Guide)

To determine Schedule 40 stainless steel pipe wall thickness in mm:

- Reference ASME Standards: Prioritize ASME B36.19M-2024 for stainless steel dimensions.

- Match NPS/DN to OD: For example, NPS 1/2″ (DN15) has a 21.3 mm outer diameter.

- Check SCH 40 Column: Cross-reference tables to find thickness (e.g., 3.73 mm for NPS 1/2).

Note: SCH 40 may not apply to very small/large pipes. For accuracy, use certified charts from ASME or trusted tools like the Engineering Toolbox.

COPY OR DOWNLOAD HERE: ASME B36.10M, 36.19M-DIMENTIONS

SCHEDULE 40 STAINLESS STEEL PIPE DIMENSIONS POWERED BY KCM SPECIAL STEEL CO.,LTD

SCHEDULE 40 STAINLESS STEEL PIPE DIMENSIONS POWERED BY KCM SPECIAL STEEL CO.,LTD

Schedule 40 (Sch40) Stainless Steel Pipe Dimensions Chart

Below is a comprehensive Schedule 40 (SCH40) stainless steel pipe size chart in inches and DN (Diameter Nominal) from 1/8″ to 60″, based on ASME B36.19 (stainless steel) and ASME B36.10 (carbon steel, referenced for dimensional consistency).

All dimensions are in millimeters (mm).

Stainless Steel Pipe Dimensions – Schedule 40 (SCH40)

| NPS (inch) | DN (mm) | Outside Diameter (OD, mm) | Wall Thickness (WT, mm) |

|---|---|---|---|

| 1/8 | 6 | 10.29 | 1.73 |

| 1/4 | 8 | 13.72 | 2.24 |

| 3/8 | 10 | 17.15 | 2.31 |

| 1/2 | 15 | 21.34 | 2.77 |

| 3/4 | 20 | 26.67 | 2.87 |

| 1 | 25 | 33.40 | 3.38 |

| 1.5 | 40 | 48.26 | 3.68 |

| 2 | 50 | 60.33 | 3.91 |

| 2.5 | 65 | 73.03 | 5.16 |

| 3 | 80 | 88.90 | 5.49 |

| 4 | 100 | 114.30 | 6.02 |

| 5 | 125 | 141.30 | 6.55 |

| 6 | 150 | 168.28 | 7.11 |

| 8 | 200 | 219.08 | 8.18 |

| 10 | 250 | 273.05 | 9.27 |

| 12 | 300 | 323.85 | 9.53 |

| 14 | 350 | 355.60 | 9.53 |

| 16 | 400 | 406.40 | 9.53 |

| 18 | 450 | 457.20 | 9.53 |

| 20 | 500 | 508.00 | 9.53 |

| 22 | 550 | 558.80 | 9.53 |

| 24 | 600 | 609.60 | 9.53 |

| 26 | 650 | 660.40 | 7.92 |

| 28 | 700 | 711.20 | 7.92 |

| 30 | 750 | 762.00 | 7.92 |

| 32 | 800 | 812.80 | 7.92 |

| 34 | 850 | 863.60 | 7.92 |

| 36 | 900 | 914.40 | 7.92 |

| 40 | 1000 | 1016.00 | 7.92 |

| 42 | 1050 | 1066.80 | 7.92 |

| 44 | 1100 | 1117.60 | 7.92 |

| 48 | 1200 | 1219.20 | 7.92 |

| 50 | 1250 | 1270.00 | 15.09 |

| 60 | 1500 | 1524.00 | 17.48 |

Key Notes:

DN (Diameter Nominal):

- Metric equivalent to NPS (e.g., NPS 2 ≈ DN 50). For sizes ≥14″, DN = NPS × 25 (e.g., NPS 14 = DN 350).

Wall Thickness (SCH40):

- NPS 1/8–12: Standard SCH40 thickness per ASME B36.19.

- NPS 14–24: SCH40 = Standard (STD) wall (9.53 mm).

- NPS 26–48: SCH40 = 7.92 mm (per ASME B36.10M for carbon steel, adopted for stainless steel due to identical SCH dimensions).

- NPS 50–60: Thickness based on industrial practice (carbon steel SCH40 adopted for stainless).

Outside Diameter (OD):

- NPS 1/8–12: Fixed values per ASME B36.19.

- NPS ≥14: OD = NPS (inches) × 25.4 (e.g., NPS 14 = 14 × 25.4 = 355.60 mm).

Materials:

- Applicable to ASTM A312 stainless steel (e.g., TP304/316).

Standards Compliance:

- ASME B36.19 (stainless steel) for NPS 1/8–24.

- ASME B36.10 (carbon steel) for NPS 26–60 (dimensions mirrored for stainless SCH40 pipes).

Critical Sizes:

- NPS 50 and 60 use thicker walls (15.09 mm, 17.48 mm) due to structural requirements. Non-standard SCH40 for these sizes is industry-derived.

Abbreviations:

- NPS: Nominal Pipe Size (inches)

- DN: Diameter Nominal (metric)

- OD: Outside Diameter

- WT: Wall Thickness

- SCH: Schedule

Disclaimer: Sizes >24″ are not formally standardized in ASME B36.19. Values for NPS 26–60 are derived from ASME B36.10M (carbon steel) and industrial practices. Verify with manufacturers for critical applications.

Introduction to Schedule 40 Stainless Steel Pipes

Schedule 40 stainless steel pipes are widely used in industrial and commercial applications due to their balance of durability and cost-effectiveness. The term “Schedule 40” refers to a standardized wall thickness classification under ASME B36.10, ensuring consistent performance across varying pressures and temperatures1. These pipes are ideal for medium-pressure systems, offering reliable strength without excessive material use.

SCH40 Stainless Steel Pipe Dimensions and Specifications Mainly

Standard dimensions for Schedule 40 stainless steel pipes range from 1/8 inch to 24 inches in nominal diameter, with wall thickness varying proportionally. For example, a 2-inch Schedule 40 pipe has an outer diameter of 2.375 inches and a wall thickness of 0.154 inches. Larger sizes, such as 6-inch pipes, maintain structural integrity with thicker walls (0.280 inches) to handle higher stress. Lengths typically span 6 meters (20 feet) for ease of transport and installation.

SCH 40 Stainless Steel Pipe Material Composition and Grades

Common grades include 304 and 316 stainless steel, known for corrosion resistance and mechanical strength. Grade 316L is preferred for harsh environments due to its enhanced molybdenum content, which resists pitting and chemical degradation. These materials comply with international standards, ensuring compatibility with global industrial requirements.

Sch40 Stainless Steel Pipe Applications and Industry Use

Schedule 40 stainless steel pipes are essential in chemical processing, oil and gas, and water distribution systems. Their robustness makes them suitable for structural frameworks, handrails, and HVAC systems. In food and pharmaceutical industries, their smooth surface prevents contamination and simplifies cleaning.

SCH 40 Stainless Steel Pipe Dimensions Standards and Compliance

ASME B36.10 and ANSI B36.19 define dimensional tolerances and testing protocols. Schedule 40 pipes are tested for hydrostatic pressure, tensile strength, and surface finish to meet safety benchmarks. Compliance with ISO and ASTM standards ensures global acceptance and interoperability.

Summary

Schedule 40 stainless steel pipes offer a versatile solution for medium-pressure applications, combining standardized dimensions, corrosion-resistant materials, and rigorous compliance. Their adaptability across industries underscores their importance in modern infrastructure.

FAQ

- What is the pressure rating of Schedule 40 pipes?

Pressure ratings vary by diameter and material but generally suit medium-pressure systems.

2. How does Schedule 40 compare to Schedule 80?

Schedule 80 has thicker walls for higher pressure, while Schedule 40 balances cost and strength.

3. Are these pipes suitable for outdoor use?

Yes, stainless steel grades like 316 resist corrosion in outdoor environments.

4. What lengths are commonly available?

Standard lengths are 6 meters (20 feet), but custom cuts can be ordered.

5. Can Schedule 40 pipes handle high temperatures?

Yes, stainless steel retains strength at elevated temperatures, ideal for thermal applications.