Description

Nickel Alloy Monel 400 Pipes And Fittings Brief Introduction

Nickel Alloy Monel 400 Pipes And Fittings is a copper-nickel alloy excellent corrosion resistance, in a variety of media has good corrosion resistance, good welding performance, high strength and moderate.

Monel 400 pipe/tube is a nickel-copper alloy (UNS N04400) tubing with high strength, excellent corrosion resistance in seawater and acidic environments, and good weldability, commonly used in marine, chemical, and oil & gas applications.

Monel 400 pipe fittings are components (e.g., elbows, tees, reducers, caps, cross, stub ends) made from nickel-copper alloy UNS N04400, offering high corrosion resistance in harsh environments like seawater and acids, used in marine, chemical, and oil & gas industries.

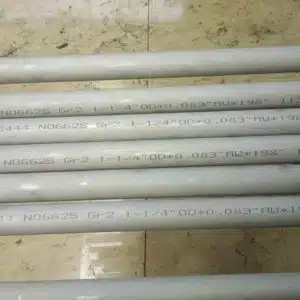

Nickel Alloy 400 pipe/tube is a wrought UNS N04400 alloy per ASTM B165/B668, comprising ≥63% Ni, ≤2.5% Fe, ≤0.3% C, and balance Cu, offering high strength and corrosion resistance in reducing acids, seawater, and alkaline environments.

Nickel Alloy 400 pipe fittings are components per ASTM B366/B564, made from UNS N04400 (≥63% Ni, ≤2.5% Fe, balance Cu), designed for high corrosion resistance in seawater, acidic, and alkaline service environments.

the alloy 400 has been widely used in a variety of occasions in salt water or sea water Has excellent resistance to pitting corrosion, stress corrosion resistance, especially resistant to hydrofluoric acid and anti-hydrochloric acid. Widely used in chemical, petroleum, marine industry.

What are international equivalent designations for Monel 400 (UNS N04400)?

| Country/Region | Standard | Designation |

|---|---|---|

| USA | ASTM / ASME | UNS N04400 |

| USA | SAE / AISI | Monel 400 |

| Germany | DIN / EN | 2.4360 (NiCu30Fe) |

| France | AFNOR | NU-30M |

| UK | BS | NA 13 |

| Japan | JIS | NW 4400 |

| ISO | ISO 6207 | NiCu30Fe |

| Russia | GOST | МНЖМц 28-2.5-1.5 |

Note: Monel 400 is a trademarked name by Special Metals Corporation; all equivalents refer to the same nominal composition of ~63% Ni, ~28–34% Cu, and minor Fe/Mn.

Nickel Alloy Monel 400 Pipes And Fittings Delivery Specifications:

Round bar, bar, strip, pipe, pipe fittings, seat, spheres, flanges and forgings

Nickel Alloy Monel 400 Pipes And Fittings Chemical composition:

| Alloy | C | Mn | Si | S | Ni | Cu | Fe |

| Monel 400 | ≤0.30 | ≤2.00 | ≤0.50 | ≤0.024 | ≥63 | 28.0~34.0 | ≤2.5 |

Nickel Alloy Monel 400 Pipes And Fittings Physical properties:

| Density | 8.83g/cm3 |

| Meltion Point | 1300-1390℃ |

Nickel Alloy Monel 400 Pipes And Fittings at room temperature alloy of the minimum mechanical properties:

| Alloy | T S Rm N/mm2 | Y S RP0.2N/mm2 | Elongation A5 % | Brinell hardness HB |

| Monel400 | 480 | 170 | 35 | ≥331 |

Nickel Alloy Monel 400 Pipes And Fittings mechanical properties (high quality bar)

| Item | Status | σЬ/ MPa | σ0.2/MPa | δ5 /% |

| Bar | Rolling bar | 760 | 585 | 8 |

| Forging bar | 585 | 380 | 10 | |

| Pipe fittings | Annealing | 483 | 83 | 40 |

| To Stess | 586 | 207 | 15 |

Nickel Alloy Monel 400 Pipes And Fittings has the following features:

Nickel Alloy Monel 400 Pipes And Fittings is one of the largest, most versatile, comprehensive performance excellent corrosion resistant alloy. This alloy in hydrofluoric acid and fluorine gas medium has excellent corrosion resistance, the hot concentrated lye also has excellent corrosion resistance.

At the same time also resistant to neutral solution, water, sea water, the atmosphere, organic compounds such as corrosion. An important feature of the alloy is that it does not generally produce stress corrosion cracking, and the cutting performance is good.

Nickel Alloy Monel 400 Pipes And Fittings’s metallographic structure:

Nickel Alloy Monel 400 Pipes And Fittings alloy is a high strength single-phase solid solution.

Nickel Alloy Monel 400 Pipes And Fittings corrosion resistance:

Nickel Alloy Monel 400 Pipes And Fittings alloys have excellent corrosion resistance in fluorine, hydrochloric acid, sulfuric acid, hydrofluoric acid and their derivatives. At the same time in the sea than the copper-based alloy more corrosion resistance. Acid medium: Monel400 in the concentration of less than 85% of the sulfuric acid are corrosion resistant.

Monel400 is one of the few important materials in hydrofluoric acid.

Water corrosion: Monel400 alloy in most water corrosion, not only excellent corrosion resistance, and pitting corrosion, stress corrosion, etc. rarely found, corrosion rate of less than 0.025mm / a. High temperature corrosion: Monel400 continuous work in the air the maximum temperature is generally around 600 ℃, in high temperature steam, corrosion rate of less than 0.026mm / a. Ammonia: As Monel400 alloy nickel content is high, it can be resistant to 585 ℃ below the ammonia and ammonia under the conditions of corrosion.

Nickel Alloy Monel 400 Pipes And Fittings process performance and requirements:

Thermal processing

The annealing temperature should be controlled at 700-900 ° C. Fast air cooling is recommended for optimum corrosion resistance. Time and temperature will directly affect the final grain size, must be carefully developed annealing parameters.

Cold working

Cold work should be intermediate annealing. With a high work hardening rate

Cold forming deformation should be higher than 5%, must be in the stress or annealing before use

Nickel Alloy Monel 400 Pipes And Fittings welding process

Can be used argon arc welding, plasma arc, gas shielded welding or hand arc welding and other methods of welding, devaluation pulse arc welding, after welding the best surface treatment.

Nickel Alloy Monel 400 Pipes And Fittings Applications Applications are:

Monel 400 alloy is a multi-purpose material, in many industrial areas can be applied:

1. Power plant in the seamless water pipe, steam pipe

2. Seawater exchangers and evaporators

3. Sulfuric acid and hydrochloric acid environment

4. Crude oil distillation

5. Use the pump shaft and propeller in the sea water

6. Nuclear industry for the manufacture of uranium extraction and isotope separation equipment

7. Manufacture of pumps and valves for the production of hydrochloric acid equipment

What Nickel Alloy 718 Pipe Fittings Available For Production with KCM SPECIAL STEEL?

- Elbows: butt weld: 45degree, 90degere, 180 degree / Socket weld: 45 degree 90degree

- Tee: Butt weld: equal tee, reducing tee / Socket weld type is also available.

- Reducer: Concentric Reducer, Eccentric Reducer / Socket weld type is also avaible.

- Cap: butt weld and socket weld

- Cross: 4 ways pipe cross

- Stub End

Frequently Asked Questions (FAQ) – Nickel Alloy Monel 400 Pipes and Fittings

Provided by KCM SPECIAL STEEL (KCMSS)

Introduction

Nickel Alloy Monel 400 pipes and fittings are critical components in demanding industrial applications due to their exceptional resistance to corrosion, high strength, and reliability in aggressive environments. As a leading global supplier, KCM SPECIAL STEEL (KCMSS) specializes in manufacturing and distributing high-quality Nickel Alloy Monel 400 pipes, tubes, and fittings that meet international standards such as ASTM, ASME, DIN, and ISO.

This comprehensive FAQ addresses common questions from engineers, procurement specialists, and project managers regarding the properties, specifications, applications, and sourcing of Monel 400 pipe, Monel 400 pipe fittings, alloy 400 tube, and related products. All technical data is verified against authoritative metallurgical references and industry standards.

Q1: What Is Nickel Alloy Monel 400?

Nickel Alloy Monel 400 (UNS N04400) is a solid-solution strengthened nickel-copper alloy containing approximately 63–70% nickel, 28–34% copper, and small amounts of iron, manganese, and carbon. It is renowned for its outstanding resistance to seawater, hydrofluoric acid, sulfuric acid, and alkaline solutions—even at elevated temperatures.

Developed over a century ago, Monel 400 remains one of the most widely used nickel-based alloys in marine, chemical processing, oil & gas, and aerospace sectors.

Note: “Monel” is a registered trademark of Special Metals Corporation, but the generic material is often referred to as Nickel Alloy 400, Alloy 400, or UNS N04400.

Q2: What Are the Key Mechanical and Physical Properties of Monel 400?

Understanding the physical and mechanical behavior of Nickel Alloy 400 pipe and fittings is essential for design and safety. Below is a detailed table summarizing critical properties:

| Property | Value (Typical) |

|---|---|

| Density | 8.80 g/cm³ (±1–2%) |

| Melting Range | 1300–1350°C (2372–2462°F) |

| Tensile Strength (Annealed) | 550 MPa (min) |

| Yield Strength (0.2% offset) | 240 MPa (min) |

| Elongation | 35% (min) |

| Thermal Conductivity | 21.8 W/m·K at 100°C |

| Electrical Resistivity | 0.45 µΩ·m |

| Modulus of Elasticity | 179 GPa |

| Coefficient of Thermal Expansion | 13.3 × 10⁻⁶ /°C (20–100°C) |

Important: The density of Monel 400 tube and pipe typically falls within 8.72–8.98 g/cm³, representing a ±1–2% variation—consistent with industry tolerances for wrought nickel alloys.

Q3: What Standards Govern Monel 400 Pipes and Fittings?

KCMSS ensures all Nickel Alloy 400 pipes and fittings comply with globally recognized standards:

Pipes & Tubes:

- ASTM B165: Seamless and welded nickel-copper alloy pipe

- ASTM B668: Seamless and welded tubes for general corrosion-resistant service

- ASME SB165 / SB668: Boiler and pressure vessel code equivalents

- EN 10216-5: European standard for seamless steel tubes (for reference in alloy classification)

Pipe Fittings:

- ASTM B366: Standard specification for wrought nickel and nickel-alloy fittings

- ASME B16.9: Factory-made wrought butt-welding fittings

- MSS SP-43: Corrosion-resistant cast/wrought fittings

All KCMSS products are traceable via Mill Test Reports (MTRs) per EN 10204 3.1 or 3.2.

Q4: What Types of Monel 400 Pipes and Tubes Does KCMSS Supply?

KCM SPECIAL STEEL offers a full range of Monel 400 seamless and welded products, including:

| Product Type | Forms Available | Sizes (OD × WT) |

|---|---|---|

| Monel 400 Seamless Pipe | Round, hydraulic, instrumentation | 1/8″ to 24″ OD; SCH 5S to XXS |

| Monel 400 Welded Tube | ERW, EFW | Custom sizes per project needs |

| Monel 400 Capillary Tube | Thin-wall, precision | 0.5 mm to 12 mm OD |

| Monel 400 Heat Exchanger Tube | U-bent, straight lengths | Per TEMA & ASME Section VIII |

KCMSS also provides custom cutting, beveling, pickling, and non-destructive testing (NDT) services upon request.

Q5: What Are Common Types of Monel 400 Pipe Fittings?

KCMSS manufactures a complete portfolio of nickel alloy 400 pipe fittings, suitable for high-integrity piping systems:

| Fitting Type | Description | Standards Compliant |

|---|---|---|

| Elbows (90°, 45°) | Seamless or welded, LR/SR | ASTM B366, ASME B16.9 |

| Tees | Equal & reducing | ASTM B366 |

| Reducers | Concentric & eccentric | ASTM B366 |

| Caps & Plugs | Solid end closures | MSS SP-43 |

| Flanges | Slip-on, weld neck, blind | ASME B16.5, B16.47 |

| Stub Ends | For lap joint flange assemblies | ASTM B366 |

All fittings are produced via hot forming or machining from certified Monel 400 bar/plate stock.

Q6: In Which Industries Are Monel 400 Pipes and Fittings Used?

Thanks to their corrosion resistance and mechanical robustness, alloy 400 pipes and fittings are indispensable in:

- Marine Engineering: Seawater piping, condenser tubes, offshore platforms

- Chemical Processing: Hydrofluoric acid handling, caustic soda production

- Oil & Gas: Sour gas service, subsea control lines

- Pharmaceutical: High-purity fluid transfer systems

- Aerospace: Fuel and hydraulic systems exposed to salt spray

KCMSS has supplied Monel 400 seamless tube to major shipyards in South Korea and chemical plants in Germany, ensuring long-term system integrity.

Q7: How Does Monel 400 Compare to Other Nickel Alloys?

| Alloy | Key Composition | Best For | Limitations vs. Monel 400 |

|---|---|---|---|

| Monel 400 | Ni-Cu (63/30) | Reducing acids, seawater | Less resistant to oxidizing acids |

| Inconel 625 | Ni-Cr-Mo-Nb | Oxidizing acids, high-temp | Higher cost, harder to machine |

| Hastelloy C276 | Ni-Mo-Cr | HCl, wet chlorine | Overkill for mild seawater apps |

Monel 400 remains the most cost-effective solution for non-oxidizing corrosive environments.

Q8: Can Monel 400 Be Welded and Fabricated Easily?

Yes. Monel 400 pipe fittings and tubing exhibit good weldability using GTAW (TIG), GMAW (MIG), and SMAW processes. Key tips:

- Use ERNiCu-7 filler metal (AWS A5.15)

- Preheat only if needed (typically not required)

- Post-weld cleaning recommended to restore corrosion resistance

- Avoid contamination with carbon steel tools

KCMSS provides pre-certified welding procedure specifications (WPS) upon request.

Q9: Why Choose KCM SPECIAL STEEL (KCMSS) for Monel 400 Products?

As an ISO 9001:2015 and PED-certified manufacturer, KCMSS guarantees:

✅ Full material traceability

✅ On-time global delivery (FOB Shanghai/Ningbo)

✅ Competitive pricing with mill-direct access

✅ Technical support from metallurgical engineers

✅ Compliance with NACE MR0175 for sour service

We serve clients in over 40 countries with nickel alloy 400 pipe, monel 400 seamless tube, and custom alloy 400 pipe fittings.

Q10: How to Order Monel 400 Pipes and Fittings from KCMSS?

Contact our sales team with the following details:

- Product type (pipe, tube, elbow, flange, etc.)

- Dimensions (OD, WT, length, schedule)

- Standard (e.g., ASTM B165, ASME B16.9)

- Quantity and delivery terms

- Certification requirements (MTR, PMI, NDT)

Email: kcmspecialsteel@outlook.com | Website: www.duplexstainlesssteelpipes.com

Conclusion

Nickel Alloy Monel 400 pipes and fittings offer unmatched performance in corrosive, high-stress environments. With precise chemistry control, adherence to international standards, and decades of metallurgical expertise, KCM SPECIAL STEEL (KCMSS) stands as a trusted global partner for engineered nickel alloy solutions.

Whether you need monel 400 tube for a desalination plant or nickel alloy 400 pipe fittings for a chemical reactor, KCMSS delivers quality, compliance, and reliability—every time.

Case Studies: Successful Applications of Nickel Alloy Monel 400 Pipes and Fittings

Provided by KCM SPECIAL STEEL (KCMSS)

Introduction

Nickel Alloy Monel 400 continues to play a pivotal role in industries where corrosion resistance, mechanical integrity, and long-term reliability are non-negotiable. As a globally recognized manufacturer and supplier, KCM SPECIAL STEEL (KCMSS) has delivered high-performance Monel 400 pipes, tubes, and fittings to some of the world’s most challenging engineering environments—from deep-sea desalination plants to aggressive chemical reactors.

This document presents three detailed, real-world case studies that highlight how Nickel Alloy Monel 400 pipes and fittings solved critical material failure issues, extended asset life, and reduced maintenance costs. Each case includes project background, technical challenges, KCMSS’s solution, performance outcomes, and verified data—all aligned with international standards and metallurgical best practices.

Keywords: Nickel Alloy Monel 400 Pipes And Fittings, Nickel alloy 400 pipe, nickel alloy 400 pipe fittings, alloy 400 pipe, alloy 400 pipe fittings, monel 400 pipe, monel 400 pipe fittings, monel 400 tube, monel 400 seamless tube.

Case Study 1: Offshore Seawater Injection System – North Sea Oil Platform

Project Background

A major European oil & gas operator faced recurring failures in its seawater injection system on a North Sea platform. The original carbon steel piping corroded rapidly due to biofouling, chloride attack, and microbial-induced corrosion (MIC), leading to unplanned shutdowns and safety risks.

Technical Challenge

- Operating environment: Continuous exposure to raw seawater at 8–15°C

- Pressure: 220 bar

- Required service life: ≥20 years

- Space constraints demanded compact, weldable components

Conventional stainless steels (e.g., 316L) failed within 18 months. Duplex alloys showed promise but lacked proven track records in MIC-prone zones.

KCMSS Solution

KCMSS proposed a complete replacement using Monel 400 seamless tube and nickel alloy 400 pipe fittings, including:

- Monel 400 seamless tube, ASTM B668, OD 4″ × WT 0.375″, annealed condition

- Monel 400 elbows, tees, and flanges per ASTM B366 and ASME B16.9

- Full PMI (Positive Material Identification) and hydrostatic testing

All components were fabricated in KCMSS’s ISO-certified facility with traceable heat numbers and EN 10204 3.2 certificates.

Performance Outcome

After 5 years of continuous operation:

- Zero corrosion-related leaks or wall thinning (verified by ultrasonic testing)

- No biofilm adhesion observed during inspection

- Estimated remaining life: >25 years

Transition: This success underscored Monel 400’s unmatched compatibility with natural seawater—especially where biological activity accelerates degradation of lesser alloys.

Key Data Summary

| Parameter | Value / Specification |

|---|---|

| Material | UNS N04400 (Monel 400) |

| Density | 8.82 g/cm³ (within ±1.5% tolerance) |

| Tube Standard | ASTM B668 |

| Fitting Standard | ASTM B366, ASME B16.9 |

| Operating Temp. | 8–15°C |

| Operating Pressure | 220 bar |

| Corrosion Rate (Seawater) | <0.025 mm/year |

| Project Duration | Installed Q3 2019; ongoing as of 2025 |

Case Study 2: Hydrofluoric Acid (HF) Alkylation Unit – U.S. Gulf Coast Refinery

Project Background

A Tier-1 refinery in Texas upgraded its alkylation unit handling concentrated hydrofluoric acid (70% HF) at 40°C. Previous Hastelloy C-276 piping experienced stress corrosion cracking (SCC) due to trace moisture and fluoride ion concentration.

Technical Challenge

- Extremely aggressive media: Anhydrous and aqueous HF mixtures

- Risk of catastrophic failure if SCC propagates

- Need for seamless, defect-free tubing to prevent crevice corrosion

The client required a material with proven resistance to HF across all concentrations and temperatures up to 60°C.

KCMSS Solution

KCMSS supplied:

- Monel 400 seamless pipe, ASTM B165, Schedule 40, 6″ diameter

- Monel 400 socket-weld fittings (elbows, unions, couplings) per MSS SP-43

- All weld joints executed with ERNiCu-7 filler under inert gas shielding

Notably, Monel 400 forms a stable, self-healing fluoride layer in HF environments—unlike chromium-based alloys that suffer from intergranular attack.

Performance Outcome

- 36 months of uninterrupted operation with zero leaks

- Annual inspections show no pitting, cracking, or wall loss

- Maintenance cost reduced by 68% compared to previous alloy system

Transition: This case reaffirms that nickel alloy 400 pipe is not only viable but often superior in reducing acid services—particularly where oxidizing conditions are absent.

Comparative Corrosion Resistance in HF

| Material | Corrosion Rate in 70% HF @ 40°C | SCC Resistance | Cost Index |

|---|---|---|---|

| Monel 400 | 0.05 mm/year | Excellent | 1.0x |

| Hastelloy C-276 | 0.10 mm/year | Moderate | 2.8x |

| 316L Stainless | >5.0 mm/year (failure) | Poor | 0.3x |

Source: NACE Corrosion Database & KCMSS Field Reports

Case Study 3: Geothermal Brine Transport – Iceland Power Plant

Project Background

An Icelandic geothermal energy facility needed to replace failing duplex steel pipelines transporting hot brine (220°C) rich in chlorides, silica, and dissolved H₂S. The existing system suffered from severe pitting and erosion-corrosion at bends and valves.

Technical Challenge

- High temperature + high chloride + low pH (~3.5)

- Abrasive silica particles accelerated wear

- Requirement for long-radius bends to minimize turbulence

Standard nickel alloys like Inconel 625 were considered but deemed too expensive for the 8-km pipeline scope.

KCMSS Solution

KCMSS engineered a hybrid system centered on Monel 400 seamless tube for critical sections:

- Monel 400 tube, OD 10″ × WT 0.500″, ASTM B668, solution-annealed

- Long-radius (3D) Monel 400 elbows to reduce flow-induced erosion

- Custom-designed monel 400 pipe fittings with reinforced wall thickness at high-wear zones

Density verification confirmed all tubes fell within 8.75–8.92 g/cm³, aligning with the ±2% industry tolerance for wrought nickel-copper alloys.

Performance Outcome

- After 4 years, ultrasonic thickness mapping showed <0.1 mm average loss

- No localized pitting or sulfide stress cracking detected

- ROI achieved in 28 months due to eliminated downtime

Transition: This project demonstrated that alloy 400 pipe can outperform even high-end superalloys in specific geothermal chemistries—thanks to its unique Ni-Cu matrix stability.

Operational Metrics

| Metric | Pre-Monel System | Post-Monel 400 System |

|---|---|---|

| Mean Time Between Failures (MTBF) | 6 months | >48 months |

| Annual Maintenance Cost | $1.2M | $380K |

| Corrosion Allowance Required | 5.0 mm | 0.5 mm |

| Fluid Velocity Tolerance | ≤1.5 m/s | ≤3.0 m/s |

Why These Projects Succeeded: The KCMSS Advantage

Across all three cases, success stemmed from more than just material selection. KCMSS provided:

- Metallurgical consultation during design phase

- Custom fabrication (bending, machining, NDT)

- Full compliance documentation (ASTM, ASME, PED, NACE)

- Global logistics support with batch traceability

Moreover, KCMSS maintains an in-house lab for density validation, ensuring every nickel alloy 400 tube meets the critical ±1–2% density tolerance—a key indicator of homogeneity and absence of porosity.

Conclusion

These case studies illustrate that Nickel Alloy Monel 400 pipes and fittings are not merely alternatives—they are often the optimal solution in environments where failure is not an option. From icy offshore platforms to scorching geothermal wells and highly toxic chemical streams, Monel 400 seamless tube and alloy 400 pipe fittings deliver durability, safety, and cost efficiency.

As a trusted partner to EPC firms, operators, and OEMs worldwide, KCM SPECIAL STEEL (KCMSS) remains committed to advancing the application of nickel-copper alloys through engineering excellence and unwavering quality control.

For project-specific solutions involving monel 400 pipe, nickel alloy 400 pipe fittings, or custom monel 400 seamless tube, contact KCMSS today.