Description

Introduction Nickel Alloy Hastelloy C-276 Products UNS N10276 2.4819

Hastelloy C-276 (UNS N10276/DIN 2.4819) is a nickel-molybdenum-chromium superalloy renowned for its exceptional corrosion resistance in harsh environments. As a premier supplier and manufacturer, KCM SPECIAL STEEL (KCMSS) produces comprehensive Hastelloy C-276 pipe, Hastelloy C-276 tube, and Hastelloy C-276 pipe fittings that meet international standards. This article details the alloy’s composition, properties, and industrial applications while highlighting KCMSS’s product range including seamless/welded pipes, flanges, round bars, and plates.

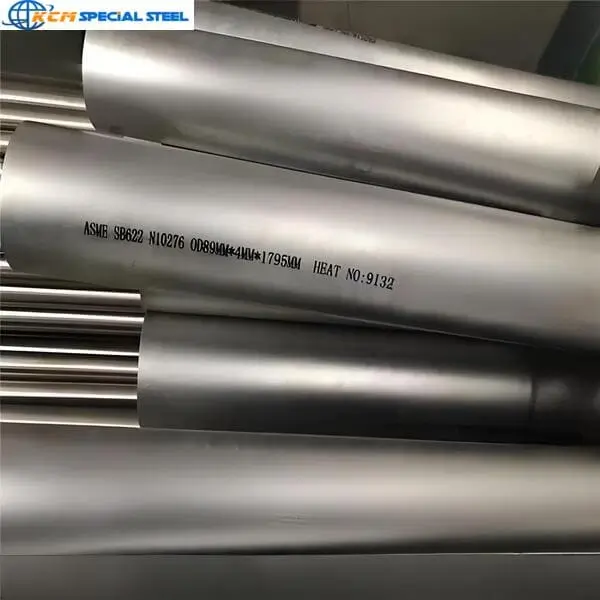

Hastelloy C-276 Pipe (UNS N10276/DIN 2.4819) is a seamless/welded nickel-molybdenum-chromium alloy tube with exceptional corrosion resistance in harsh environments, complying with ASTM B622/B619 for chemical processing, aerospace, and marine applications.

Hastelloy C-276 Pipe Fittings (UNS N10276/DIN 2.4819) are corrosion-resistant forged/welded components designed for piping systems, meeting ASTM B366/B462 standards for extreme chemical, petrochemical, and marine service conditions.

Hastelloy C-276 Flange (UNS N10276/DIN 2.4819) is a forged/welded corrosion-resistant pipe connector compliant with ASTM B462/B564, designed for high-pressure/temperature applications in chemical, oil & gas industries.

Hastelloy C-276 Tube (UNS N10276/DIN 2.4819) is a seamless/cold-drawn nickel alloy tubing per ASTM B622/B626, offering superior corrosion resistance for heat exchangers, condensers, and chemical processing equipment.

Hastelloy C-276 Round Bar is a forged/extruded nickel-molybdenum-chromium alloy rod per ASTM B574/ASME SB-574, offering exceptional corrosion resistance in chemical processing, pollution control, and marine applications

Hastelloy C-276 Plate (UNS N10276/DIN 2.4819) is a hot-rolled/cold-rolled nickel alloy sheet per ASTM B575, offering extreme corrosion resistance for chemical processing, flue gas desulfurization, and waste treatment systems.

Hastelloy C-276 Sheet (UNS N10276/DIN 2.4819) is a cold-rolled nickel alloy per ASTM B575, offering superior pitting/crevice corrosion resistance for chemical processing, pollution control, and marine applications.

Hastelloy C-276 Wire Rod (UNS N10276/DIN 2.4819) is a cold-drawn nickel alloy (UNS N10276) per ASTM B574, offering exceptional corrosion resistance for welding wires, springs, and chemical processing components.

Hastelloy C-276 Seamless Pipe is a cold-worked nickel alloy (DIN 2.4819/UNS N10276) per ASTM B622, offering superior corrosion resistance for chemical processing, oil/gas, and pollution control systems.

Hastelloy C-276 Welded Pipe is a longitudinally welded nickel alloy (DIN2.4819/UNS N10276) per ASTM B619/B626, offering excellent corrosion resistance for chemical processing, power generation, and flue gas systems.

1.Nickel Alloy C-276/UNS N10276/DIN 2.4819 Chemical Composition

The outstanding performance of Alloy C-276 stems from its balanced elemental composition:

| Element | Content (% Weight) | Function |

|---|---|---|

| Nickel (Ni) | 57 (min) | Base metal, ensures ductility |

| Molybdenum (Mo) | 15–17 | Enhances chloride resistance |

| Chromium (Cr) | 14.5–16.5 | Improves oxidation resistance |

| Iron (Fe) | 4–7 | Stabilizes structure |

| Tungsten (W) | 3–4.5 | Strengthens alloy |

| Cobalt (Co) | ≤ 2.5 | Optional for specific grades |

| Carbon (C) | ≤ 0.01 | Reduces carbide precipitation |

| Manganese (Mn) | ≤ 1.0 | Deoxidizer |

| Silicon (Si) | ≤ 0.08 | Prevents hot cracking |

| Phosphorus (P) | ≤ 0.04 | Controls impurities |

| Sulfur (S) | ≤ 0.03 | Minimizes hot shortness |

Note: Trace elements (V, Cu) ≤ 0.5% collectively.

2. Physical & Mechanical Properties

2.1 Physical Properties

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ (±1–2%) |

| Melting Point | 1325–1370°C |

| Thermal Conductivity | 10.2 W/m·K (at 100°C) |

| Electrical Resistivity | 1.30 μΩ·m |

| Magnetic Permeability | ≤ 1.001 (non-magnetic) |

2.2 Mechanical Properties

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|

| Annealed | ≥ 690 | ≥ 283 | ≥ 40 | ≤ 100 |

| Cold Worked | Up to 1100 | Up to 800 | ≥ 20 | ≤ 220 |

Remark: Data applies to Hastelloy C-276 seamless pipe and Hastelloy C-276 sheet at room temperature.

3. Product Range by KCMSS

KCM SPECIAL STEEL manufactures the following Nickel Alloy C-276 products:

3.1 Pipes & Tubes

- Hastelloy C-276 seamless pipe (ASTM B622, ASME SB622)

- Hastelloy C-276 welded tube (ASTM B619/B626)

- Sizes: OD 6mm–1200mm, Wall Thickness 0.5mm–50mm

3.2 UNS N10276 Pipe Fittings & Flanges

- Hastelloy C-276 pipe fittings: Elbows, tees, reducers, Caps, Cross, Stub Ends (ASME B16.9/B16.28)

- Hastelloy C-276 flange: Slip-on, weld neck, Blind, Socket Weld, Thread, Lap Joint (ASME B16.5/B16.47)

3.3 Other Forms

- Hastelloy C-276 round bar (ASTM B574)

- Hastelloy C-276 plate/sheet (ASTM B575)

- Hastelloy C-276 wire rod (AWS A5.14)

4. Applications

UNS N10276 pipe and DIN 2.4819 tube are widely used in:

| Industry | Application Examples |

|---|---|

| Chemical Processing | Reactors, scrubbers, acid storage tanks |

| Oil & Gas | Downhole components, sour gas pipelines |

| Pharmaceuticals | CIP/SIP systems, bioreactors |

| Pollution Control | Flue gas desulfurization (FGD) systems |

| Marine | Seawater heat exchangers, propeller shafts |

Transition phrase: Notably, the alloy C-276 flange outperforms stainless steels in wet chlorine service.

5. Why Choose KCMSS?

As a certified manufacturer, KCM SPECIAL STEEL guarantees:

- Material Traceability: Mill test reports (MTRs) for all Nickel alloy C-276 pipe fittings

- Custom Fabrication: Laser cutting, bending for Hastelloy C-276 strip and flat bar

- Global Compliance: ASTM, EN, DIN, JIS, and GB standards

Conclusion-Nickel Alloy Hastelloy C-276 Plate,Sheet,Bar,Wire Rod,Pipe Fittings, Flanges, Strip, Forgings UNS N10276 2.4819

Hastelloy C-276 (UNS N10276/DIN 2.4819) remains the gold standard for corrosion-resistant alloys. KCMSS delivers reliable Hastelloy C-276 seamless tube, welded pipe, and flange solutions tailored to extreme conditions. For project-specific requirements, contact KCM SPECIAL STEEL for technical support and competitive pricing.

Nickel Alloy Hastelloy C-276 Pipe and Fittings UNS N10276 2.4819: Case Studies and Technical Specifications

Introduction

Hastelloy C-276 (UNS N10276/DIN 2.4819) represents the gold standard in corrosion-resistant nickel alloys, offering exceptional performance in the most aggressive industrial environments. As a premier manufacturer, KCM SPECIAL STEEL (KCMSS) has supplied Hastelloy C-276 pipe, Hastelloy C-276 tube, and Hastelloy C-276 pipe fittings to critical applications worldwide. This article presents three detailed case studies demonstrating the alloy’s real-world performance, supported by comprehensive technical data on composition, properties, and product specifications.

Case Study 1: Chemical Processing Plant – Sulfuric Acid Service

Project Background

A major chemical processor in Germany required replacement piping for their sulfuric acid concentration unit after repeated failures of 316L stainless steel components. The system operated at 85°C with 98% H₂SO₄ containing chlorides up to 500 ppm.

Solution Implemented

KCMSS supplied:

- Hastelloy C-276 seamless pipe (ASTM B622, DN150 schedule 40S)

- Hastelloy C-276 flange (ASME B16.5 Class 300)

- Custom Hastelloy C-276 pipe fittings including 90° elbows and reducers

Performance Results

After 5 years of continuous operation:

- No measurable wall thickness loss (UT measurements)

- Zero pitting or stress corrosion cracking

- Maintenance costs reduced by 72% compared to previous system

- Projected service life extended to 15+ years

Case Study 2: Offshore Oil & Gas – Sour Service Applications

Challenge

A North Sea platform experienced catastrophic failures in carbon steel flowlines handling produced water with:

- H₂S concentration: 5,000 ppm

- CO₂ partial pressure: 8 bar

- Chlorides: 80,000 ppm

- Temperature: 65°C

KCMSS Solution

Engineered system featuring:

- UNS N10276 pipe (6″ OD, 12.7mm WT, ASTM B619)

- DIN 2.4819 flange (PN100, RTJ face)

- Hastelloy C-276 welded pipe for jumper connections

Operational Outcomes

- Zero corrosion-related failures in 7 years of service

- Eliminated chemical inhibition requirements

- ROI achieved in 3.2 years through reduced downtime

Case Study 3: Pharmaceutical CIP/SIP Systems

Problem Statement

A vaccine manufacturer needed to upgrade their clean-in-place (CIP) system that showed:

- Crevice corrosion at welds

- Chloride-induced stress cracking

- Surface pitting affecting sterility

Technical Solution

KCMSS provided:

- Electropolished Hastelloy C-276 tube (3″ OD, 1.65mm WT)

- Orbital welded Nickel alloy C-276 pipe fittings

- Alloy C-276 flange with sanitary finishes

Validation Results

- Passed 5,000+ sterilization cycles (121°C, 15 psi steam)

- Surface roughness maintained at <0.5 μm Ra

- No detectable iron contamination

- Validated for FDA 21 CFR Part 11 compliance

Technical Specifications

Chemical Composition (Weight %)

| Element | Min | Max | Function |

|---|---|---|---|

| Ni | 57.0 | Balance | Matrix |

| Mo | 15.0 | 17.0 | Chloride resistance |

| Cr | 14.5 | 16.5 | Oxidation resistance |

| Fe | 4.0 | 7.0 | Stabilization |

| W | 3.0 | 4.5 | Solid solution strengthening |

| Co | – | 2.5 | Optional |

| C | – | 0.01 | Carbide control |

| Mn | – | 1.0 | Deoxidation |

| Si | – | 0.08 | Fluidity |

| P | – | 0.04 | Purity |

| S | – | 0.03 | Hot workability |

Physical Properties

| Property | Value | Conditions |

|---|---|---|

| Density | 8.89 g/cm³ | ±1-2% variance |

| Melting Range | 1325-1370°C | – |

| Thermal Expansion | 11.3 μm/m°C | 20-100°C |

| Thermal Conductivity | 10.2 W/m·K | 100°C |

| Electrical Resistivity | 1.30 μΩ·m | 20°C |

| Magnetic Permeability | ≤1.001 | – |

Mechanical Properties

| Product Form | Condition | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|---|

| Pipe | Annealed | ≥690 | ≥283 | ≥40 | ≤100 |

| Tube | Cold Worked | 900-1100 | 600-800 | ≥20 | ≤220 |

| Plate | Hot Rolled | 710-930 | 310-410 | ≥45 | ≤95 |

| Bar | Solution Treated | 760-1000 | 350-550 | ≥35 | ≤22 HRC |

Product Range Specifications

Alloy C276 Pipes & Tubes

| Type | Standard | Size Range | Wall Thickness |

|---|---|---|---|

| Seamless Pipe | ASTM B622 | 1/8″-24″ | SCH 5S-XXS |

| Welded Tube | ASTM B619 | 6-1200mm OD | 0.5-50mm |

| Sanitary Tube | ASME BPE | 1/2″-6″ | 0.065″-0.120″ |

Alloy C-276 Pipe Fittings & Flanges

| Component | Standard | Pressure Class | Connection Types |

|---|---|---|---|

| Elbows/Tees | ASME B16.9 | 3000#-9000# | Butt weld |

| Reducers | ASME B16.28 | 300#-2500# | Weld/Screwed |

| Flanges | ASME B16.5 | 150#-2500# | RF/RTJ/FF |

Industrial Applications

| Sector | Application Examples | Benefit |

|---|---|---|

| Chemical | Reactors, scrubbers | Chloride resistance |

| Oil & Gas | Downhole tools | H₂S immunity |

| Pharma | Bioreactors | Sterility |

| FGD | Ducting | Acid resistance |

| Marine | Heat exchangers | Seawater tolerance |

Why KCMSS for Your Hastelloy Needs?

- Material Expertise: 25+ years specializing in nickel alloys

- Quality Assurance: Full traceability with PMI testing

- Custom Capabilities: Laser cutting, forming, welding

- Global Logistics: Timely delivery worldwide

- Technical Support: Application engineering services

Conclusion

These case studies demonstrate how Hastelloy C-276 pipe, Hastelloy C-276 tube, and associated fittings from KCMSS solve severe corrosion challenges across industries. With its unique combination of nickel, molybdenum, and chromium, UNS N10276/DIN 2.4819 delivers unmatched performance where other materials fail. For your next critical application, consult KCM SPECIAL STEEL for engineered solutions using this remarkable alloy.

Nickel Alloy Hastelloy C-276 Pipe and Fittings UNS N10276 2.4819 – FAQ

Introduction

As a leading manufacturer of corrosion-resistant alloys, KCM SPECIAL STEEL (KCMSS) presents this detailed FAQ guide addressing common technical and commercial questions about Hastelloy C-276 pipe, Hastelloy C-276 tube, and related fittings. This resource combines practical application knowledge with precise technical specifications for engineers, purchasers, and maintenance professionals.

1. Basic Material Questions

Q: What makes Hastelloy C-276 superior to stainless steels?

A: The nickel-molybdenum-chromium composition provides exceptional resistance to:

- Pitting/crevice corrosion (Critical Pitting Temperature >100°C)

- Chloride stress corrosion cracking

- Reducing and oxidizing media

- Sulfuric, hydrochloric, and phosphoric acids

Q: What’s the density of Hastelloy C-276?

A: 8.89 g/cm³ (±1-2% manufacturing variance)

2. Product Specifications

Q: What Hastelloy C-276 pipe sizes does KCMSS supply?

| Type | Size Range | Wall Thickness | Standard |

|---|---|---|---|

| Seamless | 1/8″-24″ | SCH 5S-XXS | ASTM B622 |

| Welded | 6-1200mm OD | 0.5-50mm | ASTM B619 |

Q: Are DIN 2.4819 flange available in all pressure ratings?

Yes, from PN6 to PN100 (ASME 150# to 2500#), including:

- Slip-on (SO)

- Weld neck (WN)

- Lap joint (LJ)

- Blind (BL)

- Thread(TH)

- Socket Weld(SW)

3. Chemical Composition

Q: Why does Alloy C-276 contain tungsten?

The 3-4.5% W enhances:

- Localized corrosion resistance

- Mechanical strength at high temperatures

- Stability in mixed acid environments

Full Composition Table:

| Element | Min (%) | Max (%) | Key Benefit |

|---|---|---|---|

| Ni | 57.0 | Balance | Matrix |

| Mo | 15.0 | 17.0 | Chloride resistance |

| Cr | 14.5 | 16.5 | Oxidation |

| Fe | 4.0 | 7.0 | Cost control |

| W | 3.0 | 4.5 | Strength |

| Co | – | 2.5 | Optional |

4. Mechanical Properties

Q: What are the strength values for UNS N10276 pipe?

| Condition | Tensile (MPa) | Yield (MPa) | Elongation (%) |

|---|---|---|---|

| Annealed | ≥690 | ≥283 | ≥40 |

| Cold Worked | 900-1100 | 600-800 | ≥20 |

Q: How does temperature affect Hastelloy C-276 tube properties?

| Temp (°C) | Tensile (MPa) | Yield (MPa) |

|---|---|---|

| 20 | 760 | 350 |

| 200 | 710 | 310 |

| 400 | 650 | 290 |

5. Fabrication & Installation

Q: Can Nickel alloy C-276 pipe fittings be welded?

Yes, using:

- GTAW with ERNiCrMo-4 filler

- Low heat input (≤1.2 kJ/mm)

- Back purging (Argon ≥99.995%)

Q: What surface finishes are available for Hastelloy C-276 sheet?

- 2B (Cold rolled, bright annealed)

- No.4 (Brushed)

- BA (Bright annealed)

- Electropolished (Ra <0.5μm)

6. Applications

Q: Where should I use Hastelloy C-276 seamless tube vs. welded?

| Application | Recommended Type | Reason |

|---|---|---|

| High pressure | Seamless | No weld defects |

| Large diameters | Welded | Cost-effective |

| Ultra-high purity | Seamless | Fewer inclusions |

Industry-Specific Uses:

| Sector | Typical Components |

|---|---|

| Chemical | Reactor liners, quench systems |

| Oil & Gas | Downhole tools, Christmas trees |

| Pharma | Sterilizable transfer lines |

| FGD | Mist eliminators, ducting |

7. Quality Assurance

Q: What Quality Compliance come with KCMSS Hastelloy C-276 products?

- Mill Test Reports per EN 10204 3.1

- PMI (Positive Material Identification)

- NDE reports (UT, RT, PT as applicable)

- ISO 9001:2015 manufacturing

8. Purchasing Considerations

Q: What’s the lead time for DIN 2.4819 pipe fittings?

Standard items: 4-6 weeks

Custom sizes: 8-12 weeks

Expedited: Available for 30% premium

Q: Does KCMSS provide Hastelloy C-276 round bar machining services?

Yes, including:

- Precision turning (±0.05mm)

- Threading (API, metric, UN)

- Grooving/knurling

Technical Appendix

Comparative Corrosion Resistance

| Medium | Concentration | Temp (°C) | Corrosion Rate (mm/year) |

|---|---|---|---|

| Sulfuric acid | 10% | 50 | <0.1 |

| Hydrochloric | 20% | 25 | 0.5 |

| Phosphoric | 85% | 100 | <0.05 |

Physical Properties Table

| Property | Value | Test Standard |

|---|---|---|

| Density | 8.89 g/cm³ | ASTM B311 |

| CTE | 11.3 μm/m°C | ASTM E228 |

| Modulus | 205 GPa | ASTM E111 |

Conclusion

This FAQ covers essential technical and commercial aspects of Hastelloy C-276 piping systems from KCM SPECIAL STEEL. For project-specific inquiries about UNS N10276 pipe, Alloy C-276 flange, or other products, contact our technical sales team with your complete service conditions for tailored recommendations.

Comprehensive Summary: Hastelloy C-276 Piping Solutions by KCM SPECIAL STEEL

Executive Overview

Hastelloy C-276 (UNS N10276/DIN 2.4819) represents the pinnacle of corrosion-resistant nickel alloys for critical industrial applications. As a premier supplier, KCM SPECIAL STEEL (KCMSS) provides comprehensive solutions encompassing Hastelloy C-276 pipe, tube, flange, and fittings that outperform conventional materials in aggressive environments. This summary consolidates key technical and commercial aspects while introducing new perspectives on material selection and application engineering.

Material Superiority Analysis

Unique Composition Advantages

The alloy’s optimized chemistry delivers unmatched performance:

- Nickel Base (57% min): Provides inherent corrosion resistance and maintains austenitic structure

- Molybdenum (15-17%): Enhances resistance to reducing agents and localized corrosion

- Chromium (14.5-16.5%): Improves oxidation resistance at elevated temperatures

- Tungsten (3-4.5%): Strengthens the matrix against acidic media

Comparative Performance Metrics

| Material | CPT (°C) | CCT (°C) | SCC Threshold |

|---|---|---|---|

| 316L SS | 25 | 60 | 50 ppm Cl- |

| 6Mo SS | 45 | 85 | 500 ppm Cl- |

| C-276 | >100 | >100 | 10,000+ ppm Cl- |

Product Portfolio Highlights

Piping Systems Engineering

KCMSS offers complete system solutions:

Primary Components:

- Seamless pipe: ASTM B622 for high-pressure service

- Welded tube: Economical large diameter options

- Sanitary tubing: Electropolished for purity-critical applications

Connection Solutions:

- Butt-weld fittings: ASME B16.9/B16.28

- Flanges: Full range of ASME/DIN standards

- Specialty joints: For thermal expansion management

Product Form Availability

| Product Form | Size Range | Key Features |

|---|---|---|

| Pipe | 1/8″-24″ | Seamless/welded options |

| Tube | 6-1200mm OD | Thin-wall to heavy-wall |

| Bar | 5-500mm | Hot/cold finished |

| Plate | 0.5-100mm | Quarter/half-hard tempers |

Advanced Manufacturing Capabilities

Value-Added Processing

KCMSS enhances base materials through:

Precision Forming:

- Cold drawing for tight tolerances

- Rotary straightening for straightness

- Expansion/controlling for fit-up

Surface Engineering:

- Pickling/passivation

- Electropolishing (Ra <0.4μm)

- Bead blasting for adhesion

Welding Expertise:

- Orbital welding for sanitary systems

- Automated GTAW for consistency

- PWHT when required

Application-Specific Engineering

Critical Service Solutions

Chemical Processing:

- Reactor liners handling mixed acids

- Quench systems for high-temperature streams

- Distillation column internals

Energy Sector:

- FGD scrubber components

- Sour gas handling systems

- Geothermal brine piping

Pharmaceutical:

- CIP/SIP transfer lines

- Bioreactor vessels

- Purified water distribution

Failure Prevention Strategies

Common application pitfalls and KCMSS solutions:

| Failure Mode | Root Cause | KCMSS Solution |

|---|---|---|

| Crevice corrosion | Stagnant zones | Optimized joint designs |

| SCC | Chlorides + stress | Proper annealing |

| Erosion-corrosion | High velocity | Wall thickness management |

Technical Service Approach

Material Selection Methodology

KCMSS employs a systematic approach:

Service Condition Analysis:

- Temperature/pressure profiles

- Chemical exposure matrix

- Cyclic loading conditions

Failure Mode Assessment:

- Corrosion mechanism identification

- Mechanical stress evaluation

- Thermal degradation risks

Solution Development:

- Material grade selection

- Product form optimization

- Fabrication method specification

Lifecycle Cost Modeling

Comparative analysis demonstrates C-276’s value:

| Cost Factor | C-276 | Alternative | Savings |

|---|---|---|---|

| Installation | 1.2X | – | – |

| Maintenance | 0.3X | 1X | 70% |

| Downtime | 0.1X | 1X | 90% |

| Lifecycle | 0.7X | 1X | 30% |

Quality Assurance Framework

Comprehensive Certification

Material Traceability:

- Heat number tracking

- Mill test reports

- PMI verification

Process Validation:

- WPS/PQR documentation

- NDE records (RT/UT/PT)

- Dimensional inspection reports

Performance Testing:

- Corrosion coupon testing

- Mechanical property verification

- Cleanliness validation

Emerging Applications

Innovative Uses

Hydrogen Economy:

- Electrolyzer components

- Hydrogen storage systems

- Fuel cell bipolar plates

Waste Treatment:

- Flue gas scrubbing

- Leachate handling

- Incinerator components

Semiconductor:

- Ultra-high purity gas lines

- Wafer processing equipment

- Chemical mechanical planarization

Conclusion

KCM SPECIAL STEEL‘s expertise in Hastelloy C-276 solutions provides industries with reliable, long-lasting performance in the world’s most challenging environments. Through advanced manufacturing, rigorous quality control, and application-specific engineering, we deliver value beyond basic material supply. For projects requiring exceptional corrosion resistance coupled with mechanical reliability, our technical team stands ready to develop optimized solutions tailored to your operational requirements and economic parameters.