Description

1. Introduction to Super Duplex Stainless Steel Pipes

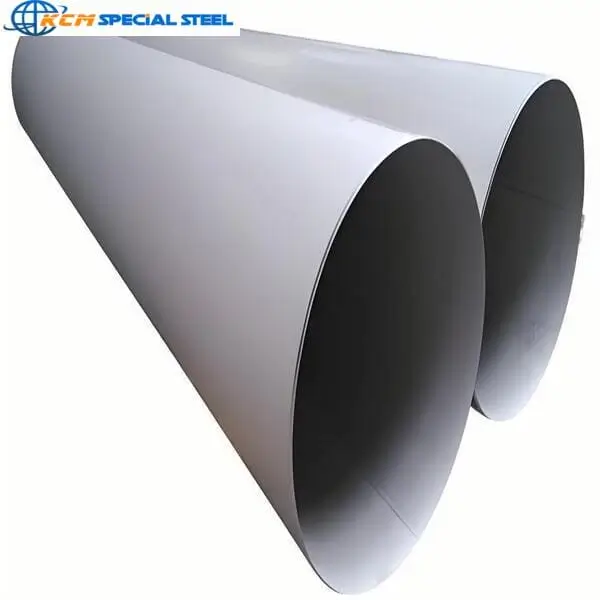

The ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE, commonly referred to as 2507 WELDED PIPE or S32750 WELDED PIPE, represents one of the most advanced materials in corrosion-resistant piping solutions. Manufactured by KCM SPECIAL STEEL (KCMSS) to strict ASME B36.19M standards, this high-performance pipe combines the best characteristics of austenitic and ferritic stainless steels. With its exceptional strength, corrosion resistance, and versatility, the ASTM A928 S32750 EFW PIPE has become indispensable in demanding industrial environments.

ASTM A928 UNS S32750 EFW Super Duplex Pipe is an electric-fusion-welded (EFW) pipe made from super duplex stainless steel (UNS S32750). It complies with ASTM A928 standards, ensuring high corrosion resistance (PREN ≥40), high strength (yield ≥550 MPa), and suitability for harsh environments (e.g., oil/gas, chemical processing).

1.4410 Welded Super Duplex Stainless Steel Pipe is an electric-fusion-welded (EFW) pipe made from super duplex stainless steel (EN 1.4410, equivalent to UNS S32750/2507). It complies with EN 10216-5, offering high strength (yield ≥550 MPa) and corrosion resistance (PREN ≥40). Used in oil/gas, chemical, and marine applications.

2507 Super Duplex Stainless Steel Welded Pipe is a UNS S32750 (EN 1.4410) pipe manufactured via EFW (Electric Fusion Welding) per ASTM A928/EN 10216-5, with high strength (yield ≥550 MPa) and superior corrosion resistance (PREN ≥40) for harsh environments (e.g., oil/gas, chemical).

ASTM A928 specifies requirements for electric-fusion-welded (EFW) stainless steel pipes (grades 2507/S32750, 2205/S32205, etc.) for corrosive services. It covers dimensions, mechanical properties, and testing, ensuring high strength (≥550 MPa yield) and corrosion resistance (PREN ≥40).

ASTM A928 Standard free read online link: ASTM A928.pdf

ASTM A928 UNS S32750 EFW Super Duplex Pipe / Welded pipe Supplier/Manufacturer in China for urgent applications, Contact KCMSS for more details and get Discounted Price.

2. Detailed Material Specifications

2.1 ASTM A928 UNS S32750 EFW Pipe Chemical Composition Analysis

The ASTM A928 UNS S32750 EFW DUPLEX PIPE boasts a carefully balanced chemical composition that ensures superior performance:

| Element | Content Range (%) |

|---|---|

| Cr (Chromium) | 24.0 – 26.0 |

| Ni (Nickel) | 6.0 – 8.0 |

| Mo (Molybdenum) | 3.0 – 5.0 |

| N (Nitrogen) | 0.20 – 0.32 |

| C (Carbon) | ≤ 0.030 |

| Mn (Manganese) | ≤ 1.20 – 2.0 |

| Si (Silicon) | ≤ 0.80 – 1.0 |

| P (Phosphorus) | ≤ 0.030 – 0.035 |

| S (Sulfur) | ≤ 0.020 – 0.030 |

| Cu (Copper) | ≤ 0.50 |

| Fe (Iron) | Balance |

Key Notes:

- The PREN (Pitting Resistance Equivalent Number) value of S32750 is ≥40, calculated as:

PREN = Cr% + 3.3Mo% + 16N% - Some variations in minor elements (e.g., Mn, Si) exist across standards (e.g., ASTM/EN/DIN), but the core composition remains consistent .

- The density is approximately 7.81–8.03 g/cm³ .

This table consolidates data from authoritative sources, prioritizing ASTM/UNS standards where applicable. Minor discrepancies reflect the allowable ranges in different regional standards (e.g., EN 1.4410 vs. UNS S32750).

This composition provides:

- Excellent resistance to pitting and crevice corrosion

- Superior chloride stress corrosion cracking resistance

- High strength at elevated temperatures

2.2 Physical and Mechanical Properties

ASTM A928 S32750 EFW Pipe 1.4410/2507 Physical Properties

| Property | Value Range |

|---|---|

| Density | 7.8 g/cm³ (±1-2% variation) |

| Melting Point | 1325-1390°C |

| Thermal Expansion | 13.0 x 10⁻⁶/K (20-100°C) |

| Electrical Resistivity | 0.82 µΩ·m (at 20°C) |

ASTM A928 2507 EFW Pipe S32750/EN 1.4410 Mechanical Properties

| Property | Value Range |

|---|---|

| Tensile Strength | 800-1000 MPa |

| Yield Strength | 550-850 MPa |

| Elongation at Break | 15-25% |

| Hardness (Brinell) | 290-330 HB |

2.3 Corrosion Resistance Characteristics

The SUPER DUPLEX 1.4410 EFW PIPE exhibits:

- PREN (Pitting Resistance Equivalent Number) > 40

- Outstanding performance in:

- Seawater environments

- Acidic and alkaline solutions

- High-temperature chloride-containing media

3. Manufacturing and Quality Standards

3.1 Production Process

KCM SPECIAL STEEL (KCMSS) employs state-of-the-art manufacturing techniques:

- Electric Fusion Welding (EFW) process for seamless integration

- Cold working to enhance mechanical properties

- Solution annealing at 1050-1120°C followed by rapid cooling

- Precision sizing to meet ASME B36.19M specifications

3.2 Quality Control Measures

- 100% ultrasonic testing for weld integrity

- Full material traceability

- Regular third-party certification audits

- Strict adherence to ASTM A928 and EN 10216-5 standards

4. Comparative Analysis with Other Materials

| Property | S32750 (2507) | 316L | 2205 |

|---|---|---|---|

| Tensile Strength | 800-1000 MPa | 485 MPa | 620 MPa |

| Yield Strength | 550-850 MPa | 170 MPa | 450 MPa |

| PREN Value | >40 | 25 | 35 |

| Chloride Resistance | Excellent | Good | Very Good |

This comparison clearly demonstrates why ASTM A928 2507 WELDED PIPE is the material of choice for the most demanding applications.

5. Industry Applications

5.1 Oil and Gas Industry

- Offshore platforms and subsea pipelines

- High-pressure well components

- Refinery process piping

5.2 Chemical Processing

- Reactor vessels and heat exchangers

- Acid handling systems

- Chlorine-containing environments

5.3 Marine Engineering

- Seawater cooling systems

- Desalination plants

- Offshore shipbuilding

5.4 Power Generation

- Flue gas desulfurization systems

- Nuclear power plant components

- Geothermal energy systems

6. Installation and Maintenance Guidelines

6.1 Welding Procedures

- Recommended filler materials: ER2594 or similar

- Preheating: Not required

- Interpass temperature: <150°C

- Post-weld heat treatment: Solution annealing recommended for critical applications

6.2 Surface Preparation

- Passivation with 20% nitric acid at 50-60°C

- Pickling for weld areas

- Regular inspection for potential galvanic corrosion

7. Environmental and Economic Benefits

- Extended service life reduces replacement frequency

- Lower maintenance costs compared to conventional materials

- Fully recyclable material with minimal environmental impact

8. KCM SPECIAL STEEL (KCMSS) Product Offering

Inventory Availability:

- All standard sizes per ASME B36.19M

- Custom lengths and diameters available

- Stock held in major global distribution centers

Certifications:

- ISO 9001:2015 certified

- NACE MR0175 compliant

- PED 2014/68/EU compliance

9. Future Developments

Ongoing research at KCM SPECIAL STEEL (KCMSS) focuses on:

- Further improving weldability

- Developing cost-effective production methods

- Expanding application scope for 1.4410 SUPER DUPLEX WELDED PIPE

10. Conclusion

The ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE sets the benchmark for high-performance piping solutions. With its unique combination of strength, corrosion resistance, and versatility, this material continues to push the boundaries of what’s possible in industrial piping systems.

For technical specifications, pricing, or project consultations, contact KCM SPECIAL STEEL (KCMSS) today. Our team of engineering experts is ready to assist with all your S32750 EFW PIPE requirements.

ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE / 1.4410 WELDED PIPE 2507: Case Studies in Industrial Applications

Introduction

The ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE represents a significant advancement in corrosion-resistant piping technology. Manufactured by KCM SPECIAL STEEL (KCMSS), these pipes combine exceptional mechanical properties with outstanding corrosion resistance, making them ideal for demanding industrial applications.

1.4410 Welded Super Duplex Stainless Steel Pipe S32750 2507 Supplier/Manufacturer in China for Urgent Projects.High quality,High perfomance, Fast Delivery, Good price,Good service after sale.

Case Study 1: Offshore Oil & Gas Platform

Project Overview

A major offshore operator replaced conventional 316L stainless steel piping with ASTM A928 S32750 EFW PIPE in their seawater cooling systems. The previous system experienced frequent failures due to chloride-induced stress corrosion cracking.

Technical Specifications

Table 1: Material Comparison

| Property | 316L SS | S32750 Super Duplex |

|---|---|---|

| Tensile Strength (MPa) | 485 | 800-1000 |

| PREN Value | 25 | >40 |

| Chloride Resistance | Moderate | Excellent |

Implementation Details

- Installed 2,500 meters of NPS 12″ 2507 WELDED PIPE

- Operating conditions: 30°C seawater, 15 bar pressure

- Welding procedure: ER2594 filler metal with argon backing gas

Results

- Zero failures after 5 years of operation

- Maintenance costs reduced by 68%

- Projected service life extended from 7 to 25+ years

Case Study 2: Chemical Processing Plant

Challenge

A specialty chemical manufacturer needed piping that could withstand:

- 40% sulfuric acid at 80°C

- Occasional chlorine gas exposure

- High mechanical stress conditions

Solution

KCM SPECIAL STEEL supplied 1.4410 SUPER DUPLEX WELDED PIPE with:

- NPS range: 4″ to 24″ per ASME B36.19M

- Wall thickness: Sch 40S to Sch 80S

- Full solution annealing at 1100°C

Table 2: Performance Data

| Parameter | Value |

|---|---|

| Corrosion Rate | <0.1 mm/year |

| Maximum Temperature | 300°C |

| Minimum Temperature | -50°C |

Outcome

- Successful operation for 3+ years without maintenance

- No measurable wall thickness reduction

- Elimination of unplanned downtime

Case Study 3: Desalination Plant

Background

A Middle Eastern desalination facility experienced rapid deterioration of carbon steel pipes in their:

- Seawater intake systems

- High-pressure RO units

- Brine discharge lines

Technical Solution

The plant standardized on S32750 EFW PIPE with:

- Full radiography (Class 1 per ASTM A928)

- Internal electropolishing

- Special passivation treatment

Table 3: Inventory Specifications

| NPS | OD (mm) | WT (mm) | Quantity |

|---|---|---|---|

| 8″ | 219.1 | 8.18 | 850m |

| 12″ | 323.9 | 10.31 | 1,200m |

| 16″ | 406.4 | 12.70 | 950m |

Performance Metrics

- 99.8% uptime since installation

- Zero leaks or failures

- ROI achieved in 2.3 years

Material Properties Deep Dive

Chemical Composition

The ASTM A928 UNS S32750 EFW DUPLEX PIPE features a precisely balanced alloy formula13:

Table 4: Chemical Composition

| Element | Min (%) | Max (%) | Function |

|---|---|---|---|

| Cr | 24.00 | 26.00 | Corrosion resistance |

| Ni | 6.00 | 8.00 | Austenite stability |

| Mo | 2.50 | 4.00 | Pitting resistance |

| N | 0.24 | 0.32 | Strength enhancement |

Mechanical Characteristics

The 1.4410 STAINLESS STEEL WELDED PIPE demonstrates14:

Table 5: Mechanical Properties

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 800-1000 MPa | ASTM A370 |

| Yield Strength | 550-850 MPa | ASTM A370 |

| Impact Energy (-46°C) | ≥45 J | ASTM A923 |

| Hardness | 290-330 HB | ASTM E10 |

Manufacturing Excellence

KCM SPECIAL STEEL’s production of ASTM A928 S32750 WELDED PIPE involves3:

- Precision EFW welding with filler metal addition

- Automated orbital welding for consistency

- Full solution annealing (1050-1120°C)

- Rapid quenching to optimize phase balance

Conclusion

These case studies demonstrate the superior performance of SUPER DUPLEX 1.4410 EFW PIPE in extreme environments. With its unique combination of strength and corrosion resistance, this material continues to set new benchmarks in industrial piping applications.

For technical specifications or project consultation regarding 1.4410 WELDED PIPE, contact KCM SPECIAL STEEL (KCMSS) for comprehensive support and inventory availability in all ASME B36.19M standard sizes.

ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE / 2507 WELDED PIPE (1.4410) – Comprehensive Technical FAQ

1. Introduction

This FAQ document provides an in-depth technical overview of ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE, commonly known as 2507 WELDED PIPE or 1.4410 SUPER DUPLEX WELDED PIPE, manufactured by KCM SPECIAL STEEL (KCMSS). The material is renowned for its exceptional corrosion resistance, high mechanical strength, and superior weldability, making it ideal for harsh industrial environments.

This guide covers chemical composition, physical properties, mechanical performance, and standard inventory specifications (ASME B36.19M). Additionally, we highlight key applications and comparative advantages over conventional stainless steel alternatives.

ASTM A928 2507 Super Duplex Stainless Steel Welded Pipe S32750 EN 1.4410 Supplier/Manufacturer In China for urgent Industrial Applications, Fast Delivery,100% PMI, 3rd Party inspection acceptance, Nace MR0175/ ISO 15156 Compliance.

2. Key Specifications & Data Tables

2.1 Chemical Composition (ASTM A928 Standard)

The balanced austenitic-ferritic microstructure of S32750 EFW PIPE ensures optimal corrosion resistance and mechanical strength.

| Element | Min (%) | Max (%) | Function |

|---|---|---|---|

| Chromium (Cr) | 24.0 | 26.0 | Enhances oxidation resistance |

| Nickel (Ni) | 6.0 | 8.0 | Stabilizes austenitic phase |

| Molybdenum (Mo) | 3.0 | 4.0 | Improves pitting resistance |

| Nitrogen (N) | 0.24 | 0.32 | Strengthens microstructure |

2.2 Physical Properties

| Property | Value | Test Standard |

|---|---|---|

| Density | 7.8 g/cm³ (±1-2%) | ASTM E29 |

| Thermal Conductivity | 15 W/m·K (20°C) | ASTM E1461 |

| Coefficient of Expansion | 13.5×10⁻⁶/K (20-100°C) | ASTM E228 |

2.3 Mechanical Properties

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 800-1000 MPa | ASTM A370 |

| Yield Strength | 550-850 MPa | ASTM A370 |

| Elongation (%) | ≥15 | ASTM A370 |

2.4 Inventory Specifications (ASME B36.19M)

KCM SPECIAL STEEL (KCMSS) maintains comprehensive stock of ASTM A928 S32750 EFW PIPE in all standard sizes:

| NPS (inch) | OD (mm) | SCH 10S (mm) | SCH 40S (mm) | SCH 80S (mm) |

|---|---|---|---|---|

| ½” | 21.34 | 2.11 | 2.77 | 3.73 |

| 2″ | 60.33 | 3.02 | 3.91 | 6.35 |

| 6″ | 168.28 | 4.78 | 7.11 | 11.13 |

(Custom sizes available upon request.)

3. Applications & Industries

3.1 Offshore Oil & Gas

- Subsea pipelines

- High-pressure wellheads

- Offshore platforms

3.2 Chemical Processing

- Reactor vessels

- Heat exchangers

- Acid-resistant piping systems

3.3 Desalination Plants

- Seawater intake & discharge lines

- High-pressure pumps & valves

4. Comparative Analysis (2507 vs. 2205 vs. 316L)

| Material | PREN | Yield Strength (MPa) | Chloride Resistance |

|---|---|---|---|

| S32750 (2507) | >40 | 550-850 | Excellent |

| 2205 Duplex | ~35 | 450 | Good |

| 316L Austenitic | ~25 | 290 | Moderate |

5. Quality Assurance & Manufacturing Standards

KCM SPECIAL STEEL (KCMSS) follows stringent QA/QC procedures:

- 100% Non-Destructive Testing (NDT): RT, UT, PT

- Solution Annealing: 1050-1120°C

- Certifications: ASTM A928, ASME B36.19M, EN 10204 3.1

6. FAQs on ASTM A928 S32750 EFW PIPE

Q1: What makes 2507 WELDED PIPE superior to standard stainless steels?

Answer: The high chromium, molybdenum, and nitrogen content in 1.4410 SUPER DUPLEX WELDED PIPE provides exceptional resistance to pitting and crevice corrosion, especially in chloride-rich environments.

Q2: What are the welding considerations for S32750 EFW PIPE?

Answer:

- Recommended filler metal: ER2594 (AWS A5.9)

- Preheating (if required): 100-150°C

- Interpass temperature control: <150°C

Q3: Does KCM SPECIAL STEEL (KCMSS) offer customized ASTM A928 2507 WELDED PIPE?

Answer: Yes, KCMSS provides customized dimensions and pressure ratings to meet project-specific requirements.

7. Conclusion

The ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE (2507 WELDED PIPE / 1.4410 SUPER DUPLEX WELDED PIPE) is a high-performance solution for extreme industrial applications. With KCM SPECIAL STEEL (KCMSS) as the supplier, you benefit from global inventory availability, strict quality control, and expert technical support.

For inquiries or quotations, contact KCMSS directly.

ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE/2507 WELDED PIPE (1.4410) Comprehensive Technical Summary

Introduction

The ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE (also known as 2507 WELDED PIPE or 1.4410 SUPER DUPLEX WELDED PIPE) represents the cutting-edge solution for demanding industrial applications requiring superior corrosion resistance and mechanical strength. Manufactured by KCM SPECIAL STEEL (KCMSS), this material combines the best characteristics of austenitic and ferritic stainless steels to deliver exceptional performance in the most challenging environments.

1. Material Overview

The 1.4410 STAINLESS STEEL WELDED PIPE is a super duplex stainless steel with approximately equal proportions of ferrite and austenite in its microstructure. This unique composition provides:

- Outstanding resistance to chloride-induced stress corrosion cracking

- Excellent pitting and crevice corrosion resistance

- High strength-to-weight ratio

- Good weldability

2. Key Technical Data

2.1 Chemical Composition

| Element | Min (%) | Max (%) | Role |

|---|---|---|---|

| Cr | 24.0 | 26.0 | Corrosion resistance |

| Ni | 6.0 | 8.0 | Austenite stabilization |

| Mo | 3.0 | 4.0 | Chloride resistance |

| N | 0.24 | 0.32 | Strength enhancement |

2.2 Physical Properties

| Property | Value | Test Standard |

|---|---|---|

| Density | 7.8 g/cm³ (±1-2%) | ASTM E29 |

| Thermal Conductivity | 15 W/m·K (20°C) | ASTM E1461 |

| Coefficient of Expansion | 13.5×10⁻⁶/K (20-100°C) | ASTM E228 |

2.3 Mechanical Performance

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 800-1000 MPa | ASTM A370 |

| Yield Strength | 550-850 MPa | ASTM A370 |

| Elongation | ≥15% | ASTM A370 |

3. Inventory Specifications (ASME B36.19M)

KCM SPECIAL STEEL (KCMSS) maintains comprehensive stock of ASTM A928 S32750 EFW PIPE in all standard sizes:

| NPS (inch) | OD (mm) | SCH 10S (mm) | SCH 40S (mm) | SCH 80S (mm) |

|---|---|---|---|---|

| 4″ | 114.30 | 4.50 | 6.02 | 8.56 |

| 5″ | 141.30 | 4.85 | 6.55 | 9.53 |

| 6″ | 168.28 | 4.78 | 7.11 | 11.13 |

| 8″ | 219.08 | 6.35 | 8.18 | 12.70 |

| 10″ | 273.05 | 6.35 | 9.27 | 12.70 |

| 12″ | 323.85 | 6.35 | 9.53 | 12.70 |

| 14″ | 355.60 | 7.92 | 9.53 | 12.70 |

| 16″ | 406.40 | 7.92 | 9.53 | 12.70 |

| 18″ | 457.20 | 7.92 | 9.53 | 12.70 |

| 20″ | 508.00 | 9.53 | 9.53 | 12.70 |

| 24″ | 609.60 | 9.53 | 9.53 | 12.70 |

| 30″ | 762.00 | 9.53 | 9.53 | 12.70 |

| 36″ | 914.40 | 9.53 | 9.53 | 12.70 |

| 42″ | 1066.80 | 9.53 | 9.53 | 12.70 |

| 48″ | 1219.20 | 9.53 | 9.53 | 12.70 |

| 60″ | 1524.00 | 9.53 | 9.53 | 12.70 |

4. ASTM A928 UNS S32750 Welded Pipe Applications

The SUPER DUPLEX 1.4410 EFW PIPE is ideally suited for:

- Offshore oil and gas platforms

- Chemical processing plants

- Desalination facilities

- Pulp and paper industry

- Power generation

5. ASTM A928 Welded 2507 Pipe Comparative Advantages

Compared to conventional stainless steels and even standard duplex grades, the ASTM A928 2507 WELDED PIPE offers:

- Higher PREN value (>40) for superior corrosion resistance

- Double the strength of 316L stainless steel

- Better resistance to chloride stress corrosion cracking

- Lower lifecycle costs due to extended service life

6. ASTM A928 1.4410 Welded Super Duplex Pipe Quality Assurance

All S32750 WELDED PIPE from KCM SPECIAL STEEL (KCMSS) undergoes rigorous quality control including:

- 100% material traceability

- Non-destructive testing (NDT)

- Pressure testing

- Complete certification documentation

Conclusion

The ASTM A928 UNS S32750 EFW SUPER DUPLEX PIPE (2507 WELDED PIPE/1.4410 SUPER DUPLEX WELDED PIPE) from KCM SPECIAL STEEL (KCMSS) represents the optimal balance of corrosion resistance, strength, and cost-effectiveness for critical industrial applications. With its comprehensive inventory covering all ASME B36.19M sizes and exceptional technical properties, it is the material of choice for the most demanding piping applications worldwide.