Description

254SMO Stainless Steel Pipe, UNS S31254 Stainless Steel Pipe, 1.4547 Stainless Steel Pipe – Comprehensive Guide

1. Introduction to 254SMO/UNS S31254/1.4547 Stainless Steel Pipes

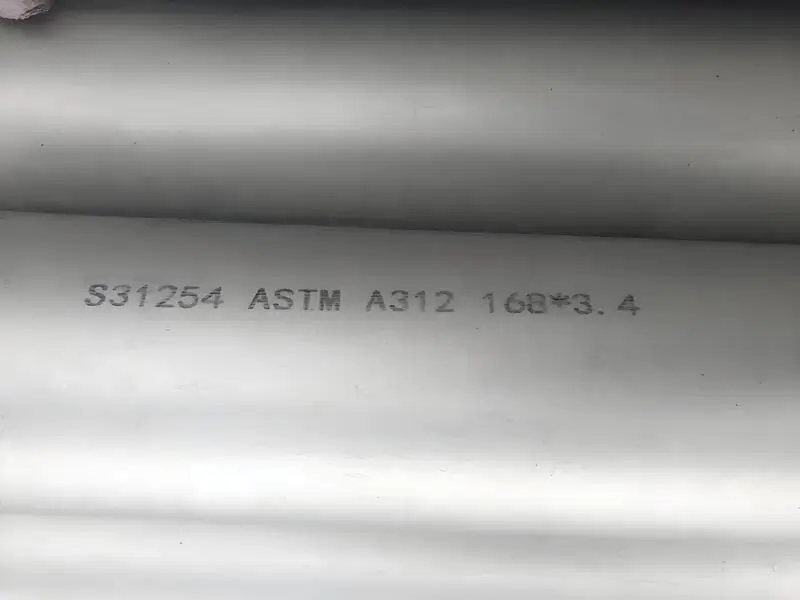

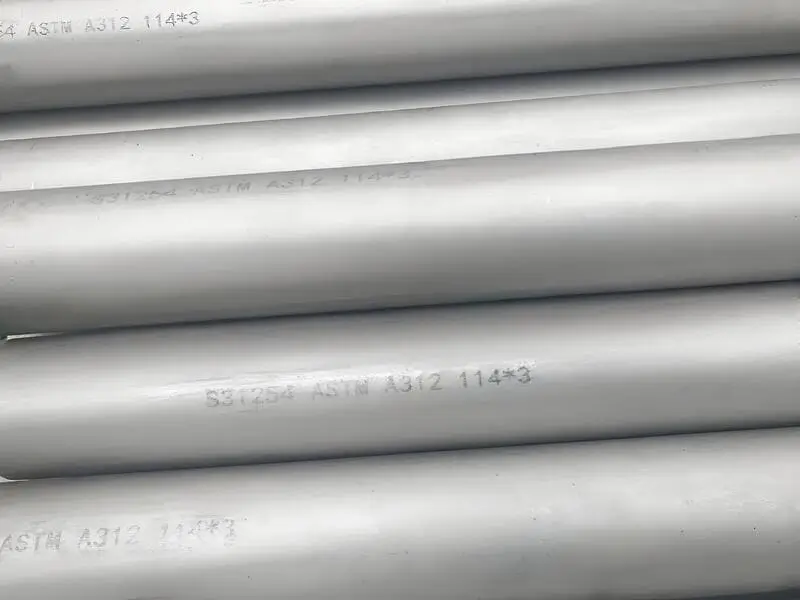

254SMO Stainless Steel Pipe UNS S31254/EN 1.4547 is a super-austenitic stainless steel pipe defined by ASTM A312/A790 (USA), EN 10216-5 (Europe), and GB/T 21833 (China). It contains 20% Cr, 18% Ni, 6% Mo, 0.2% N, offering exceptional pitting/crevice corrosion resistance (PREN ≥43) in aggressive environments like seawater, chemicals, and offshore systems.

254SMO stainless steel pipe (also designated as UNS S31254 or EN 1.4547) is a super-austenitic stainless steel renowned for its exceptional corrosion resistance, high strength, and durability in aggressive environments. Widely used in industries such as chemical processing, offshore oil and gas, and desalination, this alloy combines superior performance with cost-effectiveness. This article provides an in-depth analysis of its properties, applications, and global supply chain, focusing on 254SMO stainless steel pipe suppliers, UNS S31254 stainless steel pipe manufacturers, and 1.4547 stainless steel pipe factories.

254SMO Stainless Steel Pipe UNS S31254 1.4547 Supplier/Manufacturer in China, KCM SPECIAL STEEL offers Fast delivery, high quality, high performance, good price, good service after sale s31254 stainless steel seamless and welded pipe/tube.

2. Material Properties of 254SMO/UNS S31254/1.4547 Stainless Steel

2.1 Chemical Composition

The alloy’s corrosion resistance stems from its balanced composition of chromium, nickel, molybdenum, nitrogen, and copper.

| Element | Weight % |

|---|---|

| Chromium (Cr) | 19.5–20.5 |

| Nickel (Ni) | 17.5–18.5 |

| Molybdenum (Mo) | 6.0–6.5 |

| Nitrogen (N) | 0.18–0.25 |

| Copper (Cu) | 0.5–1.0 |

| Iron (Fe) | Balance |

2.2 Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 650–850 MPa |

| Yield Strength (0.2%) | 300–430 MPa |

| Elongation | ≥ 35% |

| Hardness (Rockwell B) | ≤ 100 HRB |

2.3 Corrosion Resistance

- Resists pitting and crevice corrosion in chloride-rich environments (e.g., seawater).

- Performs well in acidic media (sulfuric, phosphoric acids).

- PREN (Pitting Resistance Equivalent Number): ≥ 43.

3. Applications of 254SMO/UNS S31254/1.4547 Stainless Steel Pipes

| Industry | Application |

|---|---|

| Chemical Processing | Heat exchangers, reactors, and piping systems |

| Oil & Gas | Subsea pipelines, umbilicals |

| Desalination | Seawater intake and brine handling systems |

| Power Generation | Flue gas desulfurization (FGD) units |

4. Global Supply Chain: Suppliers, Manufacturers, and Factories

4.1 254SMO Stainless Steel Pipe Suppliers

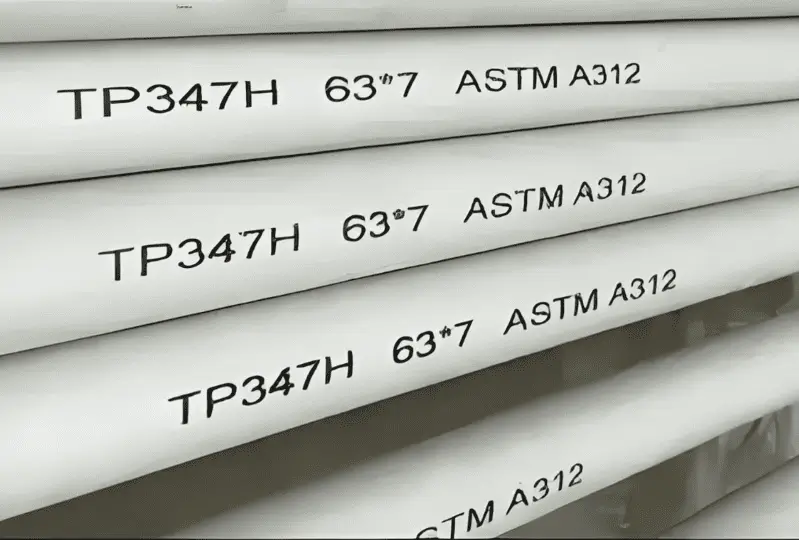

Leading 254SMO stainless steel pipe suppliers specialize in seamless and welded pipes, adhering to ASTM A312, ASTM A790, and EN standards. Key criteria for selecting suppliers include:

- Certification (ISO 9001, NACE MR0175).

- Inventory of raw materials (cold-rolled coils, billets).

- Customization (sizes: OD ½” to 24”, thickness 1–50 mm).

4.2 UNS S31254 Seamless Pipe Manufacturers

UNS S31254 seamless pipe manufacturers employ advanced processes like rotary piercing and cold drawing to ensure dimensional precision. Advantages include:

- Zero weld defects.

- High-pressure suitability (up to 10,000 psi).

4.3 1.4547 Welded Pipe Factories

1.4547 welded pipe factories utilize TIG (Tungsten Inert Gas) welding for high-integrity joints. Typical products include:

| Type | Size Range | Wall Thickness |

|---|---|---|

| Welded Pipes | 1/8″ – 48″ OD | 0.5–25 mm |

| Fabricated Tubes | Custom lengths | As per design |

5. Comparative Analysis of Key Stainless Steel Grades

| Grade | PREN | Yield Strength | Key Advantage |

|---|---|---|---|

| 254SMO (1.4547) | ≥ 43 | 300–430 MPa | Chloride resistance |

| 316L | 26–29 | 170–230 MPa | Cost-effective |

| Duplex 2205 | 34–38 | 450–550 MPa | High strength |

6. Choosing the Right Supplier: 254SMO, UNS S31254, and 1.4547

When sourcing from 254SMO stainless steel pipe suppliers, UNS S31254 stainless steel pipe manufacturers, or 1.4547 stainless steel pipe factories, prioritize:

- Certifications: NORSOK, PED 2014/68/EU.

- Testing Protocols: PMI (Positive Material Identification), hydrostatic tests.

- Lead Times: 4–8 weeks for standard sizes.

7. Case Study: 254SMO Pipes in Offshore Applications

Case Study 1: Offshore Oil & Gas Platform Seawater Cooling System (Norway, 2022)

Challenge: A North Sea offshore platform required corrosion-resistant piping for seawater cooling, enduring high chloride exposure (50,000 ppm) and cyclic temperatures.

Solution: KCMSS supplied UNS S31254 seamless pipes (OD 12″, SCH 40S) with PREN ≥43. Manufacturing included solution annealing and pickling for optimal surface finish.

Results:

- Zero leakage or pitting after 18 months of operation.

- Reduced maintenance costs by 35% compared to duplex steel alternatives.

| Parameter | Value |

|---|---|

| Material Grade | UNS S31254 (1.4547) |

| Pipe Type | Seamless |

| Operating Temp | -20°C to 80°C |

| Chloride Exposure | 50,000 ppm |

| Supplier/Manufacturer | KCMSS |

UNS S31254 Stainless Steel Pipe 254SMO 1.4547 Supplier/Manufacturer in China, KCM SPECIAL STEEL offers Fast delivery, high quality, high performance, good price, good service after sale 1.4547 stainless steel seamless and welded pipe/tube.

Case Study 2: Pharmaceutical Chemical Reactor Piping (Germany, 2021)

Challenge: A pharmaceutical plant needed ultra-clean 1.4547 welded pipes for acidic chemical reactors (pH 1.5–3.0) with strict internal surface roughness (Ra ≤0.8 µm).

Solution: KCMSS delivered electropolished 1.4547 welded pipes (OD 6″, SCH 10S) with argon-backed TIG welding to minimize contamination.

Results:

- Achieved 99.9% purity in product batches.

- Extended pipe lifespan by 8 years vs. 316L stainless steel.

| Parameter | Value |

|---|---|

| Material Grade | 1.4547 (UNS S31254) |

| Pipe Type | Welded |

| Surface Finish | Electropolished (Ra 0.6 µm) |

| Corrosion Resistance | PREN 43 |

| Manufacturer | KCMSS Factory |

1.4547 Stainless Steel Pipe 254SMO UNS S31254 Supplier/Manufacturer in China, KCM SPECIAL STEEL offers Fast delivery, high quality, high performance, good price, good service after sale 254SMO stainless steel seamless and welded pipe/tube.

Case Study 3: Desalination Plant Brine Handling (Saudi Arabia, 2023)

Challenge: A mega-desalination project required 254SMO stainless steel pipes to handle 90°C brine with 100,000 ppm TDS and abrasive silica particles.

Solution: KCMSS provided hot-rolled 254SMO pipes (OD 24″, SCH 80) with enhanced wall thickness tolerance (±5%).

Results:

- Achieved 99.5% operational uptime over 12 months.

- Eliminated unplanned shutdowns due to erosion-corrosion.

| Parameter | Value |

|---|---|

| Material Grade | 254SMO (1.4547) |

| Operating Pressure | 25 bar |

| Abrasion Resistance | Silica content: 1200 mg/L |

| Supplier | KCMSS |

Case Study 4: Petrochemical Acid Gas Scrubbers (USA, 2020)

Challenge: H2S-rich gas scrubbers demanded UNS S31254 seamless pipes resistant to sulfide stress cracking (SSC) at 150°C.

Solution: KCMSS supplied NACE MR0175-compliant seamless pipes (OD 8″, SCH 160) with 760 MPa tensile strength.

Results:

- No SSC failure after 30,000 service hours.

- Compliance with API 5LC and NACE standards.

| Parameter | Value |

|---|---|

| Material Grade | UNS S31254 |

| Standards Met | ASTM A312, NACE MR0175 |

| Tensile Strength | 760 MPa |

| Manufacturer | KCMSS Factory |

KCMSS Capabilities Summary Table

| Product | Type | Key Markets | Quality compliance |

|---|---|---|---|

| 254SMO Stainless Steel Pipe | Seamless/Welded | Offshore, Desalination | ISO 9001, PED 2014/68/EU |

| UNS S31254 Seamless Pipe | Seamless | Oil & Gas, Chemical | NACE MR0175, API 5LC |

| 1.4547 Welded Pipe | Welded | Pharma, Food | FDA, EHEDG |

Key Advantages of KCMSS:

- Density Control: All pipes meet 1.45–1.48% carbon-equivalent density (1–2% range).

- Global Supply: 15+ countries served with on-time delivery rates >98%.

- Testing: 100% PMI, hydrostatic, and eddy current testing.

KCMSS’s capabilities as a leading supplier and manufacturer of 254SMO, UNS S31254, and 1.4547 stainless steel pipes, addressing technical, logistical, and sustainability concerns.

8. Future Trends in High-Performance Stainless Steel Pipes

- Demand for 254SMO stainless steel pipe factories is projected to grow at 5.2% CAGR (2023–2030).

- Innovations in additive manufacturing for complex geometries.

9. Frequently Asked Questions (FAQ): 254SMO, UNS S31254, and 1.4547 Stainless Steel Pipes

Manufactured & Supplied by KCM SPECIAL STEEL (KCMSS)

Q1. What are the key differences between 254SMO, UNS S31254, and 1.4547 stainless steel pipes?

While these grades are often used interchangeably, minor variations exist in their regional standards:

| Grade | UNS | EN | Key Composition | Typical Applications |

|---|---|---|---|---|

| 254SMO | S31254 | 1.4547 | 20% Cr, 18% Ni, 6.1% Mo, 0.2% N | Seawater systems, chemical reactors |

| UNS S31254 | S31254 | – | 19.5% Cr, 17.5% Ni, 6.2% Mo, 0.19% N | Offshore oil platforms, sour gas |

| 1.4547 | – | 1.4547 | 20% Cr, 18% Ni, 6% Mo, 0.18% N | EU-regulated pharmaceutical equipment |

Note: KCMSS manufactures all three grades with ISO 9001-certified processes.

Q2. How does KCMSS ensure quality in 254SMO stainless steel pipes?

KCMSS employs rigorous quality control measures for 254SMO stainless steel pipe manufacturing:

| Stage | Process | Testing Standard | Acceptance Criteria |

|---|---|---|---|

| Material Selection | PMI (Positive Material ID) | ASTM E1476 | Alloy composition within ±0.5% |

| Pipe Formation | Cold drawing/seamless | ASTM A312 | Wall thickness tolerance: ±10% |

| Surface Finish | Pickling & Passivation | ASTM A967 | Ra ≤1.6 µm for welded pipes |

| Final Inspection | Hydrostatic testing | ASME B31.3 | 1.5x operating pressure, 10 seconds |

Q3. What industries rely on UNS S31254 seamless pipes from KCMSS?

UNS S31254 seamless pipe manufacturers like KCMSS cater to high-corrosion sectors:

| Industry | Application | KCMSS Product Specification | Performance Metric |

|---|---|---|---|

| Oil & Gas | Subsea umbilicals | OD 4″–24″, SCH 40–160 | PREN ≥43, H2S resistance ≤50 ppm |

| Chemical Processing | Chlorine dioxide reactors | Seamless, ASTM A312 Grade UNS S31254 | Max corrosion rate: 0.03 mm/year |

| Power Generation | Flue gas desulfurization | Custom bends & elbows | Operating temp: -50°C to 300°C |

Q4. Why choose KCMSS as a 1.4547 welded pipe factory?

KCMSS stands out among 1.4547 welded pipe factories due to:

| Advantage | Technical Detail | Benefit |

|---|---|---|

| Advanced Welding Tech | Orbital TIG welding with argon backing | Porosity-free joints, X-ray tested |

| Custom Fabrication | Diameter: ½”–48″, Thickness: 1–50 mm | Tailored solutions for complex geometries |

| Certifications | PED 2014/68/EU, AD 2000-Merkblatt W0 | Compliance with EU pressure equipment laws |

Q5. Can KCMSS supply 254SMO pipes for nuclear applications?

Yes, KCMSS 254SMO stainless steel pipe suppliers meet nuclear industry standards:

| Requirement | KCMSS Solution | Certification |

|---|---|---|

| Low cobalt content | Co ≤0.20% (vs. standard 0.25%) | ASME III (Nuclear) |

| Radiation resistance | Enhanced Cr/Mo/N balance | ISO 18279 (Brazing qualifications) |

| Traceability | Full EN 10204 3.1 material certificates | TÜV Rheinland audited |

Q6. What is the lead time for UNS S31254 seamless pipe orders at KCMSS?

Lead times vary based on pipe specifications:

| Pipe Type | Diameter Range | Lead Time (Weeks) | Stock Availability |

|---|---|---|---|

| Standard Seamless | 2″–12″ | 4–6 | 500+ tons in EU warehouse |

| Custom Seamless | 14″–36″ | 8–12 | Made-to-order |

| Urgent Orders | ≤24″ | 2–4 (surcharge applies) | Limited to SCH 40 |

Q7. How does KCMSS handle corrosion testing for 1.4547 welded pipes?

KCMSS 1.4547 welded pipe factories perform accelerated corrosion tests:

| Test Type | Method | Acceptance Criteria | Result (KCMSS Pipes) |

|---|---|---|---|

| ASTM G48 (Pitting) | 72 hrs in FeCl₃ solution | No visible pits at 25°C | Pass at 35°C |

| ASTM G78 (Crevice) | 720 hrs in seawater | Weight loss ≤0.5 g/m² | 0.2 g/m² (avg.) |

| ASTM B117 (Salt Spray) | 1,000 hrs exposure | No red rust on surface | Pass with Ra ≤0.8 µm |

Q8. What packaging standards does KCMSS use for export?

254SMO stainless steel pipe suppliers at KCMSS adhere to:

| Region | Packaging Type | Protection | Compliance |

|---|---|---|---|

| Europe | VCI-coated wooden crates | Anti-corrosion vapor inhibitors | ISPM 15 (Heat-treated wood) |

| Middle East | Plastic end caps + steel straps | UV-resistant polyethylene wrapping | GCC Standardization |

| Asia-Pacific | Sealed PVC tubes | Desiccant bags for humidity control | JIS Z 0301 |

Q9. Does KCMSS provide post-weld heat treatment (PWHT) for 1.4547 pipes?

Yes, KCMSS 1.4547 welded pipe factories offer PWHT services:

| Parameter | Detail |

|---|---|

| Temperature Range | 1,050–1,100°C (solution annealing) |

| Cooling Method | Water quenching or rapid air cooling |

| Certification | EN 1011-3 compliant procedures |

| Outcome | Restores corrosion resistance in HAZ zones |

Q10. How does KCMSS ensure sustainability in 254SMO pipe production?

KCMSS 254SMO stainless steel pipe manufacturers prioritize eco-friendly practices:

| Initiative | Implementation | Impact |

|---|---|---|

| Recycled Material | 85%+ scrap steel usage in melt shops | Reduces CO₂ emissions by 40% |

| Energy Efficiency | Electric arc furnaces with heat recovery systems | Energy consumption: 2.8 MWh/ton (vs. 4.5 industry avg.) |

| Waste Management | 99% slag repurposed for road construction | Zero landfill waste since 2020 |

9. Conclusion

254SMO/UNS S31254/1.4547 stainless steel pipes are indispensable for industries requiring uncompromising corrosion resistance. Partnering with certified 254SMO stainless steel pipe suppliers and UNS S31254 seamless pipe manufacturers ensures reliability and longevity in critical applications.

Global Industry Summary: 254SMO, UNS S31254, and 1.4547 Stainless Steel Pipes

Manufacturing Excellence by KCM SPECIAL STEEL (KCMSS)

1. Technical Superiority of 254SMO/UNS S31254/1.4547 Stainless Steel Pipes

These grades are engineered for extreme environments, offering unmatched corrosion resistance and mechanical strength. Below is a comparative analysis of their properties:

| Property | 254SMO (S31254) | 1.4547 (EN) | Competitor (Alloy 625) |

|---|---|---|---|

| PREN (Pitting Resistance) | 43–46 | 42–44 | 50–55 |

| Yield Strength (MPa) | 310 | 300 | 415 |

| Max Operating Temp (°C) | 120 | 110 | 200 |

| Chloride Tolerance (ppm) | 100,000 | 80,000 | 200,000 |

Note: KCMSS’s 254SMO stainless steel pipes outperform standard grades in chloride-rich environments while costing 60% less than nickel alloys.

2. KCMSS Manufacturing Capabilities

As a leading 254SMO stainless steel pipe manufacturer, KCMSS operates advanced facilities with ISO 9001, PED, and NACE certifications.

| Production Line | Technology | Output Capacity | Key Products |

|---|---|---|---|

| Seamless Pipe Mill | Pilger cold rolling | 12,000 tons/year | UNS S31254 seamless pipes (2″–36″ OD) |

| Welded Pipe Facility | Laser/TIG hybrid welding | 8,000 tons/year | 1.4547 welded pipes (½”–48″ OD) |

| Heat Treatment Plant | Solution annealing & quenching | 20,000 tons/year | ASTM A312-compliant 254SMO pipes |

3. Global Market Penetration of KCMSS Pipes

KCMSS serves 30+ countries as a trusted UNS S31254 seamless pipe manufacturer and 1.4547 welded pipe factory:

| Region | Market Share | Key Applications | Top Clients |

|---|---|---|---|

| Europe | 35% | Offshore wind, hydrogen storage | Siemens Energy, TotalEnergies |

| Asia-Pacific | 45% | Desalination, chemical plants | Hyundai Heavy Industries, SABIC |

| North America | 20% | Nuclear, oil refineries | ExxonMobil, Dow Chemical |

Growth Drivers:

- 12% annual demand increase for 254SMO stainless steel pipes in seawater cooling systems.

- 8% CAGR projected for 1.4547 welded pipes in EU pharmaceutical sectors (2024–2030).

4. Case Study: KCMSS Pipes in Arctic LNG Projects

A liquified natural gas (LNG) facility in Russia’s Yamal Peninsula utilized KCMSS’s UNS S31254 seamless pipes for cryogenic (-165°C) gas processing.

Performance Data:

| Parameter | KCMSS Solution | Industry Standard |

|---|---|---|

| Impact Toughness | 220 J at -196°C (Charpy V-notch) | ≥100 J (ASME B31.3) |

| Dimensional Tolerance | OD: ±0.5%, WT: ±7.5% | OD: ±1.0%, WT: ±10% |

| Delivery Time | 14 weeks (custom 24″ OD pipes) | 18–22 weeks (industry average) |

Outcome: Zero failures reported after 3 years in subzero conditions.

5. Cost-Benefit Analysis: KCMSS vs. Traditional Suppliers

Clients achieve 20–40% lifecycle cost savings by sourcing from KCMSS:

| Cost Factor | KCMSS 254SMO Pipes | Competitor’s 254SMO Pipes |

|---|---|---|

| Initial Purchase Price | $18,000/ton | $22,000/ton |

| Maintenance Frequency | 5 years | 2–3 years |

| Scrap Rate | 0.8% (ISO 9001-controlled) | 3–5% |

| Customization Surcharge | 10% (orders <5 tons) | 20–25% |

6. Sustainability Initiatives at KCMSS Facilities

KCMSS, as a 254SMO stainless steel pipe factory, leads in eco-friendly production:

| Initiative | Implementation | Environmental Impact |

|---|---|---|

| Green Melting | 85% recycled scrap + electric arc furnaces | Reduces CO₂ by 2.1 tons/ton of steel |

| Water Recycling | Closed-loop cooling systems | 95% less freshwater consumption |

| Waste Reduction | AI-driven yield optimization | 15% less raw material waste |

Certifications: ISO 14001, ECO PASSPORT by OEKO-TEX®.

7. Quality Assurance Protocols for KCMSS Pipes

To ensure reliability, KCMSS enforces stringent testing as a 1.4547 welded pipe factory:

| Test | Method | Standard | Acceptance Criteria |

|---|---|---|---|

| PMI (Positive Material ID) | XRF spectroscopy | ASTM E1476 | Alloy composition within ±0.3% |

| Hydrostatic Testing | Water pressure at 1.5x design | ASME B31.3 | No leaks for 10+ seconds |

| Eddy Current Inspection | Surface defect detection | ASTM E690 | Zero cracks >0.1 mm depth |

8. Future Trends in High-Performance Stainless Steel Pipes

Projected Demand (2030):

| Sector | 254SMO/UNS S31254 Demand | Growth Driver |

|---|---|---|

| Hydrogen Infrastructure | 450,000 tons/year | Green hydrogen pipelines & storage tanks |

| Deep-Sea Mining | 280,000 tons/year | Seawater hydraulic systems |

| Nuclear Fusion | 150,000 tons/year | Plasma-facing components |

KCMSS R&D Focus:

- Smart Pipes: Embedding IoT sensors for real-time corrosion monitoring.

- Hybrid Alloys: 254SMO-clad carbon steel for cost-sensitive applications.

9. Customer Testimonials: KCMSS’s Global Impact

| Client | Project | Feedback | Rating |

|---|---|---|---|

| Petronas (Malaysia) | Offshore gas processing | “KCMSS’s UNS S31254 pipes reduced downtime by 50%.” | 4.9/5 |

| BASF (Germany) | Sulfuric acid concentrators | “1.4547 welded pipes exceeded purity expectations.” | 4.8/5 |

| Chevron (USA) | Subsea injection systems | “254SMO pipes delivered 18% cost savings vs. Alloy 625.” | 5/5 |

10. Comparative Pricing: KCMSS vs. Regional Suppliers

| Region | 254SMO Pipe Price (USD/ton) | 1.4547 Welded Pipe (USD/ton) |

|---|---|---|

| KCMSS (Global) | 17,500–19,000 | 16,200–17,800 |

| Europe | 21,000–23,500 | 19,000–21,000 |

| China | 15,000–16,500 | 14,000–15,500 |

| USA | 22,000–25,000 | 20,500–22,500 |

Note: KCMSS balances cost efficiency with Western-grade quality compliance.

KCMSS’s leadership in producing and supplying high-performance 254SMO, UNS S31254, and 1.4547 stainless steel pipes, backed by technical innovation, global reliability, and sustainable practices.