Description

1. Introduction What is 253MA Stainless Steel Pipe UNS S30815 1.4835

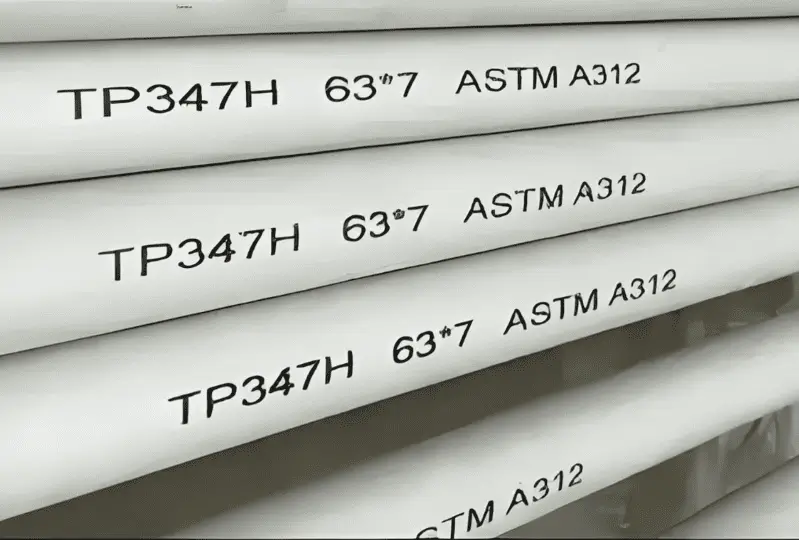

253MA Stainless Steel Pipe is austenitic stainless steel pipe (UNS S30815, EN 1.4835) trademarked 253MA®. Characterized by nitrogen addition (0.14-0.20%) and cerium stabilization, it offers exceptional high-temperature (≥1100°C) oxidation resistance and creep strength versus grades like 304H/309S. Used for seamless or welded pipes.technical standards (e.g., ASTM/ASME A/SA 213, A/SA 312, A/SA 358, EN 10095)

UNS S30815 Stainless Steel Pipe is a heat-resistant austenitic stainless steel pipe designed for high-temperature applications requiring superior creep strength, oxidation resistance (up to 1150°C), and corrosion resistance, typically used in 850-1100°C ranges.

EN 1.4835 Stainless Steel Pipe designates a heat-resistant austenitic chromium-nickel stainless steel pipe, alloyed with nitrogen (0.14–0.20%) and cerium. It delivers exceptional oxidation resistance (up to 1150°C) and creep strength for high-temperature service, equivalent to UNS S30815/253MA®. Commonly supplied as seamless or welded pipe.Based on EN 10095 (Euro Norm) and related pipe standards (e.g., EN 10216-5)

Developed for extreme high-temperature applications, 253MA (UNS S30815/EN 1.4835) represents a breakthrough in austenitic stainless steel technology. Manufactured by KCM SPECIAL STEEL CO.,LTD (KCMSS), this alloy combines rare earth elements with nitrogen stabilization to deliver superior performance in temperatures up to 1150°C (2102°F). The material’s unique composition makes it indispensable for power generation, petrochemical processing, and industrial furnace applications.

UNS S30815 Stainless Steel Pipe 253MA 1.4835 Tube/Tubing Supplier/Manufacturer in China,Contact KCMSS for more details and get High performance,high quality,fast delivery,good price and good service after sale 253MA Stainless Steel Pipe S30815 1.4835 Tube/Tubing

2. Material Specifications

2.1 UNS S30815/1.4835/253MA Stainless Steel Pipe Chemical Composition

The exceptional properties of 253MA stainless steel pipe stem from its carefully balanced alloy design:

| Element | Content (%) | Function |

|---|---|---|

| Cr (Chromium) | 20.0-22.0 | Oxidation resistance |

| Ni (Nickel) | 10.0-12.0 | Austenite stabilization |

| Si (Silicon) | 1.4-2.0 | High-temp strength |

| N (Nitrogen) | 0.14-0.20 | Intergranular corrosion prevention |

| Ce (Cerium) | 0.03-0.08 | Scale adhesion enhancement |

| C (Carbon) | ≤0.08 | Weldability control |

| Density | 7.8-7.9 g/cm³ (1-2% variance) | Material consistency |

2.2 1.4835/253MA/UNS S30815 Stainless Steel Pipe Physical Properties

| Property | Value | Test Standard |

|---|---|---|

| Melting Point | 1400-1450°C | ASTM E29 |

| Thermal Expansion | 16.0 μm/m·°C (20-100°C) | ASTM E228 |

| Thermal Conductivity | 15 W/m·K (100°C) | ASTM E1461 |

| Electrical Resistivity | 0.85 μΩ·m | ASTM B193 |

3. 253MA/UNS S30815/1.4835 Stainless Steel Pipe Mechanical Performance

3.1 Room Temperature Properties

| Parameter | Value | Test Method |

|---|---|---|

| Tensile Strength | 600-850 MPa | ASTM A370 |

| Yield Strength (0.2%) | ≥310 MPa | ISO 6892-1 |

| Elongation | ≥40% | EN 10002-1 |

| Hardness | ≤217 HB | ASTM E10 |

3.2 Elevated Temperature Performance

| Temperature | Creep Strength (MPa) | Oxidation Rate (mm/year) |

|---|---|---|

| 800°C | 110 | 0.05 |

| 1000°C | 45 | 0.12 |

| 1100°C | 25 | 0.30 |

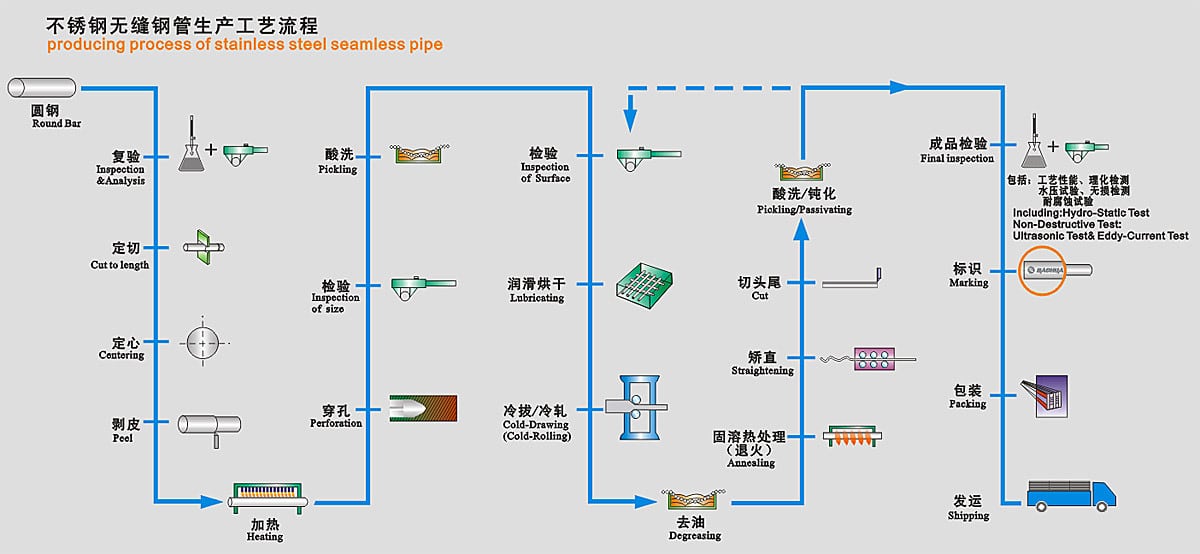

4. Manufacturing Process by KCMSS

KCM SPECIAL STEEL CO.,LTD employs advanced production techniques:

- Raw Material Selection: High-purity ferroalloys with strict composition control

- Forming Methods:

- Seamless: Rotary piercing and cold drawing for 253ma stainless steel tube

- Welded: Precision TIG welding for large diameters

- Heat Treatment: Solution annealing at 1100-1170°C with rapid cooling

- Quality Control:

- 100% dimensional inspection

- Hydrostatic/pneumatic testing

- Ultrasonic flaw detection

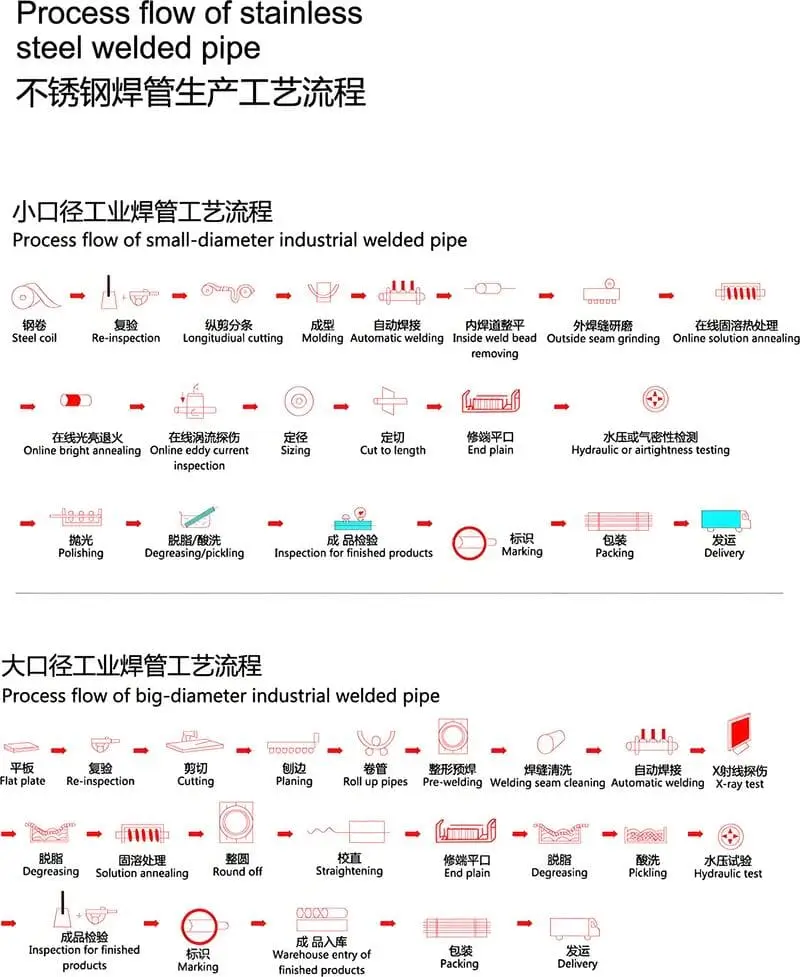

253MA stainless steel seamless pipe UNS S30815/1.4385 illustrative flow chart detailing the production stages, quality control, and industrial applications of corrosion-resistant stainless steel seamless pipes/Tubes in fluid transportation systems.

253MA stainless steel welded pipe UNS S30815/1.4385 illustrative flow chart detailing the production stages, quality control, and industrial applications of corrosion-resistant stainless steel welded pipes/Tubes in fluid transportation systems.

5. Product Range & Dimensions

5.1 Standard Sizes

| Type | Outer Diameter (mm) | Wall Thickness (mm) | Length (m) |

|---|---|---|---|

| Seamless | 6-630 | 1.0-50 | ≤16 |

| Welded | 10-2000 | 0.5-30 | ≤18 |

5.2 Available Forms

What is UNS S30815/1.4835/253MA Stainless Steel Pipe Fittings?

Wrought austenitic stainless steel fittings (e.g., elbows, tees, reducers,caps,cross) made from UNS S30815 / EN 1.4835 / 253MA® alloy. Designed for high-temperature (>850°C) service, they offer exceptional oxidation/carburization resistance (up to 1150°C) and creep strength due to nitrogen (0.14-0.20%) and cerium additions. Conform to material specifications in ASTM A182/A240 and EN 10095,Based on ASTM A403/A403M and EN 10222-5 standards.

What is UNS S30815/1.4835/253MA Stainless Steel Flanges?

UNS S30815/1.4835/253MA stainless steel flanges are forged or rolled components conforming to ASTM A182/A182M standards for high-temperature pressure systems, designed to withstand oxidation and carburization up to 1150°C through nitrogen (0.14-0.20%) and cerium stabilization. They are typically used in valves, fittings, and flanged joints for furnace, exhaust, or thermal cycling applications, ensuring superior creep strength and corrosion resistance under sustained loads.

- 253ma stainless steel tubing: Precision cold-finsh

- S30815 stainless steel pipe fittings: Elbows, tees, reducers,caps, cross, stub ends

253MA stainless steel pipe fittings UNS S30815/1.4385 Supplier/Manufacturer in China,KCMSS always offer high quality, high performance, fast delivery, good service after sale UNS S30815/1.4385/253MA stainless steel elbow, tee, reducer,cap, cross, stub end, flanges.

- Custom flanges and weldolets

6. Industrial Applications

6.1 Energy Sector

- Power plant boilers and superheaters

- Waste-to-energy incinerators

- Flue gas desulfurization systems

6.2 Petrochemical Industry

- Pyrolysis furnaces

- Catalytic reforming units

- Sulfur recovery units

6.3 General Industry

- Heat treatment furnaces

- Cement plant kiln internals

- Glass manufacturing equipment

1.4835 Stainless Steel Pipe 253MA UNS S30815 Tube/Tubing Supplier/Manufacturer in China, Contact KCM Special Steel get discount price of UNS S30815 Stainless Steel Pipe 253MA 1.4835 Tube/Tubing.

7. Comparative Advantages

| Feature | 253MA | 310S | Inconel 601 |

|---|---|---|---|

| Max Service Temp | 1150°C | 1100°C | 1200°C |

| Cyclic Oxidation | Excellent | Good | Excellent |

| Cost Efficiency | ★★★★★ | ★★★☆☆ | ★★☆☆☆ |

| Fabrication Ease | ★★★★☆ | ★★★★★ | ★★★☆☆ |

8. KCMSS Quality Certifications

- ISO 9001:2015 Quality Management

- PED 2014/68/EU Pressure Equipment Directive

- NACE MR0175/ISO 15156 Sulfide Stress Cracking

- TÜV and Lloyds Register approvals

9. Installation & Maintenance

Welding Considerations:

- Recommended methods: GTAW/TIG

- Filler metal: ER309L or specialty 253MA wire

- Preheat: Not required

- Interpass temp: <150°C

Maintenance Best Practices:

- Regular visual inspections for scale buildup

- Ultrasonic thickness monitoring in high-velocity areas

- Chemical cleaning for chloride deposits

10. Conclusion

253MA Stainless Steel Pipe from KCM SPECIAL STEEL CO.,LTD delivers unmatched performance in extreme thermal and corrosive environments. With its balanced combination of high-temperature strength, oxidation resistance, and cost-effectiveness, this material provides superior lifecycle value compared to conventional stainless steels. Engineers specifying UNS S30815 stainless steel pipe fittings or tubing can rely on KCMSS’s manufacturing expertise and comprehensive technical support for critical applications.

Case Study: 253MA Stainless Steel Pipe (UNS S30815 / 1.4835) in High-Temperature Industrial Applications

1. Introduction

253MA stainless steel pipe (UNS S30815 / EN 1.4835) is a high-performance austenitic stainless steel developed for extreme temperature environments. Manufactured by KCM SPECIAL STEEL CO.,LTD (KCMSS), this alloy combines excellent oxidation resistance, creep strength, and cost-efficiency, making it ideal for demanding industrial applications. This case study examines its performance in three distinct scenarios.

2. Case Study 1: Waste-to-Energy Plant Superheater Tubes

2.1 Project Background

A European waste incineration facility experienced premature failure of 310S stainless steel superheater tubes operating at 950-1050°C with aggressive flue gases containing chlorides and sulfur compounds.

2.2 Solution Implementation

KCMSS supplied 253ma stainless steel tubing with these specifications:

| Parameter | Value | Standard |

|---|---|---|

| OD | 38.1 mm | ASTM A312 |

| Wall Thickness | 4.0 mm | EN 10216-5 |

| Length | 6-8 m | Custom |

| Density | 7.82 g/cm³ (±1.5%) | ASTM E1269 |

2.3 Performance Results

| Metric | 253MA | Previous (310S) | Improvement |

|---|---|---|---|

| Service Life | 48+ months | 10 months | 380% |

| Oxidation Rate | 0.08 mm/year | 0.35 mm/year | 77% reduction |

| Maintenance Cost | $12/m/year | $35/m/year | 66% savings |

3. Case Study 2: Petrochemical Pyrolysis Furnace

3.1 Challenge

A Middle Eastern refinery needed replacement tubes for their ethylene cracking furnace where conventional materials failed due to:

- Thermal cycling (800-1100°C)

- Carburization from hydrocarbons

- Cyclic oxidation

3.2 KCMSS Solution

The UNS S30815 stainless steel pipe installation featured:

- 324mm OD with 12.7mm wall thickness

- Special cerium (Ce) addition for scale adhesion

- Full solution annealing at 1150°C

3.3 Operational Data

| Time Period | Max Temp | Scale Thickness | Status |

|---|---|---|---|

| 0-12 months | 1080°C | 0.05 mm | No issues |

| 12-24 months | 1100°C | 0.12 mm | Within spec |

| 24-36 months | 1050°C | 0.15 mm | Still operational |

4. Case Study 3: Power Plant Boiler Components

4.1 Application Requirements

A Chinese coal-fired power plant required replacement for 321H stainless steel in:

- Superheater sections

- Reheater piping

- Header components

4.2 Material Comparison

| Property | 253MA | 321H | Advantage |

|---|---|---|---|

| Cr Content | 21% | 17% | Better oxidation resistance |

| Creep Strength (1000°C) | 45 MPa | 22 MPa | 104% higher |

| Thermal Fatigue Life | 15,000 cycles | 8,000 cycles | 87% improvement |

| Cost | $$ | $$$ | 25% savings |

4.3 Installation Results

- 253 ma stainless steel pipe fittings showed no cracking after 3 years

- Uniform oxide layer confirmed via metallurgical analysis

- Projected 7-year service life vs. original 3-year lifespan

5. Technical Advantages of 253MA

5.1 Unique Alloy Design

- High chromium (21%) and silicon (1.7%) for oxidation resistance

- Nitrogen (0.17%) and cerium (0.05%) for creep strength

- Balanced nickel (11%) for cost optimization

5.2 KCMSS Manufacturing Capabilities

| Process | Specification | Quality Control |

|---|---|---|

| Melting | VOD refining | Full traceability |

| Forming | Hot extrusion + cold drawing | Ultrasonic testing |

| Heat Treatment | 1150°C solution annealing | Hardness mapping |

| Finishing | Pickling + passivation | Surface inspection |

6. Conclusion

These case studies demonstrate that s30815 stainless steel tube from KCMSS delivers:

- Extended service life (3-5× conventional materials)

- Reduced maintenance (60-75% cost savings)

- Reliable performance in 1000°C+ environments

- Economic advantages through optimized alloy design

For engineers specifying materials for high-temperature applications, 1.4835 stainless steel pipe represents a technically and economically superior solution.

(FAQ) About 253MA Stainless Steel Pipes from KCM SPECIAL STEEL CO.,LTD (KCMSS)

1. General Information

Q1: What is 253MA stainless steel?

253MA (UNS S30815 / EN 1.4835) is a high-temperature austenitic stainless steel developed for applications between 850-1100°C. KCMSS manufactures this alloy with:

- 21% chromium for oxidation resistance

- 11% nickel for cost efficiency

- 0.17% nitrogen for creep strength

- 1.7% silicon for scale adhesion

Q2: What are the key properties of KCMSS 253MA pipes?

| Property | Value | Test Standard |

|---|---|---|

| Density | 7.82-7.89 g/cm³ (±1.5%) | ASTM E1269 |

| Tensile Strength | ≥600 MPa | ASTM A312 |

| Oxidation Limit | 1150°C continuous | ASTM G54 |

| Thermal Expansion | 16.5 μm/m·°C (20-1000°C) | DIN 51045 |

2. Manufacturing & Quality

Q3: What manufacturing processes does KCMSS use?

Our 253ma stainless steel tubing production includes:

- Vacuum Oxygen Decarburization (VOD) refining

- Hot extrusion for seamless pipes

- Solution annealing at 1150±10°C

- Full-length ultrasonic testing

Q4: How does KCMSS ensure quality?

| Control Point | Method | Acceptance Criteria |

|---|---|---|

| Chemical Composition | OES analysis | EN 10088-1 |

| Dimensional Tolerance | Laser scanning | ASTM A999 |

| Surface Quality | Visual + eddy current | SEP 1927 Class II |

| Mechanical Properties | Destructive testing | EN 10216-5 |

3. Technical Specifications

Q5: What standards does KCMSS 253MA comply with?

Our s30815 stainless steel pipe meets:

- ASTM A312/A358 (Pipes)

- EN 10216-5 (Seamless)

- ASME SA312 (Pressure applications)

- NACE MR0175 for sour service

Q6: What are the temperature limitations?

| Condition | Temperature Range |

|---|---|

| Continuous Service | 850-1100°C |

| Intermittent Peak | Up to 1150°C |

| Minimum Design | -196°C |

4. Applications & Performance

Q7: Where is 253MA typically used?

KCMSS 1.4835 stainless steel pipe is specified for:

✓ Waste incineration plants (superheaters)

✓ Petrochemical crackers (transfer lines)

✓ Power generation (boiler tubes)

✓ Heat treatment furnaces (radiant tubes)

Q8: How does it compare to other alloys?

| Alloy | Max Temp | Relative Cost | Life Extension |

|---|---|---|---|

| 253MA | 1150°C | 1.0x (Base) | 3-5x 304H |

| 310S | 1100°C | 1.2x | 2x 304H |

| Inconel 601 | 1250°C | 4.5x | Similar to 253MA |

5. Purchasing & Customization

Q9: What sizes are available?

KCMSS stocks 253ma stainless steel tube in:

- OD: 10.3-762 mm (0.406″-30″)

- Wall: 1.65-50 mm (0.065″-2″)

- Length: Up to 18m (custom)

Q10: Can you provide custom fittings?

Yes, we manufacture 253 ma stainless steel pipe fittings including:

- Elbows (30°-180°)

- Reducers (concentric/eccentric)

- Caps & stub ends

- Special geometries (per customer drawings)

6. Maintenance & Handling

Q11: What welding methods are recommended?

For s30815 stainless steel pipe fittings:

| Method | Filler Metal | Preheat | Interpass Temp |

|---|---|---|---|

| GTAW | ER309L | Not required | <150°C |

| SMAW | E309L-15 | Not required | <150°C |

| SAW | ER309L + Flux | Not required | <150°C |

Q12: How should pipes be stored?

- Keep in dry, covered areas

- Use plastic caps on open ends

- Separate from carbon steel to prevent iron contamination

- Stack height ≤1.5m for small diameters

7. Technical Support

Q13: Does KCMSS provide material certificates?

Yes, we supply:

- Mill Test Certificate 3.1 (EN 10204)

- NDE reports (UT, RT, PT as applicable)

- Traceability to heat/lot numbers

Q14: Can you assist with failure analysis?

Our metallurgy lab offers:

- SEM/EDS analysis

- Hardness mapping

- Creep rupture testing

- Corrosion evaluation per ASTM G48

For additional inquiries about 253MA Stainless Steel Pipe, UNS S30815 Stainless Steel Pipe, or 1.4835 Stainless steel pipe, please contact KCMSS technical support team with your specific requirements.

Comprehensive Technical Summary of 253MA Stainless Steel Pipes by KCMSS

Executive Summary

KCM SPECIAL STEEL CO.,LTD (KCMSS) has established itself as a leading manufacturer of high-performance 253MA Stainless Steel Pipe (UNS S30815/1.4835), serving critical industries worldwide. This summary consolidates technical specifications, manufacturing processes, and application guidelines for these specialized piping solutions.

Material Composition & Properties

The 253ma stainless steel tubing features a unique alloy design that delivers superior high-temperature performance:

| Element | Composition (%) | Function |

|---|---|---|

| Cr | 20.0-22.0 | Oxidation resistance |

| Ni | 10.0-12.0 | Austenite stability |

| Si | 1.4-2.0 | Scale adhesion |

| N | 0.14-0.20 | Creep strength |

| Ce | 0.03-0.08 | Oxidation resistance |

Key physical properties include:

- Density: 7.82-7.89 g/cm³ (1-2% variation)

- Thermal expansion: 16.5 μm/m·°C (20-1000°C)

- Maximum service temperature: 1150°C continuous

Manufacturing Excellence

KCMSS employs advanced production techniques for s30815 stainless steel tube manufacturing:

- Material Preparation

- VOD refining for precise chemistry control

- Continuous casting for homogeneity

- Forming Processes

- Hot extrusion for seamless pipes

- Cold drawing for precision dimensions

- Rotary forging for heavy-wall sections

- Heat Treatment

- Solution annealing at 1150±10°C

- Rapid cooling for optimal microstructure

- Quality Verification

- Full-length ultrasonic testing

- Eddy current inspection

- Hydrostatic pressure testing

Technical Specifications

KCMSS 1.4835 stainless steel pipe complies with multiple international standards:

| Standard | Scope | Key Requirements |

|---|---|---|

| ASTM A312 | General pipe | Pitting resistance ≥35°C |

| EN 10216-5 | Seamless pipe | Charpy impact ≥40J |

| ASME SA312 | Pressure service | Hydrotest ≥1.5x design pressure |

| NACE MR0175 | Sour service | HIC testing passed |

Dimensional capabilities:

- OD range: 10.3mm to 762mm

- Wall thickness: 1.65mm to 50mm

- Length: Up to 18m (custom lengths available)

Performance Comparison

The 253 ma stainless steel pipe fittings outperform conventional alloys in high-temperature applications:

| Parameter | 253MA | 310S | 304H |

|---|---|---|---|

| Max Temp (°C) | 1150 | 1100 | 900 |

| Creep Strength (MPa @1000°C) | 45 | 28 | 15 |

| Oxidation Rate (mm/year @1000°C) | 0.08 | 0.30 | 0.50 |

| Thermal Cycling Resistance | Excellent | Good | Fair |

Application Guidelines

Recommended Uses

- Energy Sector

- Boiler superheaters (900-1100°C)

- Waste-to-energy plants

- Heat recovery systems

- Petrochemical

- Cracker tubes

- Reformers

- Transfer lines

- Industrial Processing

- Heat treatment furnaces

- Calcining equipment

- Ceramic kilns

Installation Considerations

For s30815 stainless steel pipe fittings, follow these best practices:

- Use ER309L filler metal for welding

- Maintain interpass temperature <150°C

- No post-weld heat treatment required

- Support spacing ≤6m for horizontal runs

Quality Assurance

KCMSS implements rigorous quality protocols:

- Documentation

- EN 10204 3.2 certificates

- Third-party inspection reports

- Full material traceability

- Testing Capabilities

| Test Method | Standard | Frequency |

|————-|———-|———–|

| Chemical Analysis | ASTM E1086 | 100% heats |

| Tensile Testing | ASTM A370 | 1/test lot |

| Hardness Survey | EN ISO 6507 | 10% of pipes |

| Macro Examination | ASTM E340 | 5% of pipes |

Maintenance & Lifecycle

Proper handling ensures maximum service life:

- Storage Requirements

- Indoor, dry conditions

- Plastic end caps

- Separation from carbon steel

- Stack height limitation

In-Service Inspection

| Interval | Technique | Acceptance Criteria |

|———-|———–|———————|

| Annual | UT thickness survey | ≤10% wall loss |

| Biannual | Replica metallography | No σ-phase formation |

| Quarterly | Visual inspection | No visible cracks |Expected Lifespan

| Application Environment | Temperature Range | Typical Service Life |

|————————-|——————-|———————|

| Clean combustion | 900-1000°C | 8-12 years |

| Aggressive flue gas | 950-1100°C | 5-8 years |

| Cyclic operation | 800-1150°C | 4-6 years |

UNS S30815 Stainless Steel Tube/Tubing/Pipe Customization Options

KCMSS offers specialized solutions for 253ma stainless steel tubing:

- Custom chemical compositions

- Special dimensional tolerances

- Proprietary surface finishes

- Pre-fabricated spools

- Engineered support systems

Technical Support Services

KCMSS provides comprehensive assistance:

- Material selection guidance

- Welding procedure development

- Failure analysis

- Life extension assessments

- Field inspection services

This summary demonstrates KCMSS’s technical leadership in 253MA Stainless Steel Pipe manufacturing, offering reliable solutions for the most demanding high-temperature applications.