Description

310 / 310S STAINLESS STEEL PIPE SUPPLIER BRIEF INTRODUCTION

310 / 310S stainless steel pipe, also known as tp310S ( SS310S ) stainless steel, is an austenitic chromium nickel stainless steel with excellent oxidation resistance and corrosion resistance. Due to the high percentage of chromium and nickel, it has much better creep strength and can continue to operate at high temperatures, with good high temperature resistance.

310 / 310s stainless steel pipe supplier is a hollow long round steel, mainly is widely used in petroleum, chemical, medical, food, light industry, machinery, instrument and other industrial pipeline and mechanical structure parts, etc.

In addition, in bending and torsion strength, the weight is lighter, so it is also widely used to make mechanical parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns and shells.

NAME:310S STAINLESS STEEL PIPE METERIAL: SUPER AUSTENITIC STAINLESS STEEL

APPLICATIONS: OIL,CHEMICAL,FOOD,LIGHT INDUSTRY,ETC., DENSITY: 8.0g/CM³

310s stainless steel pipe supplier( 06cr25ni20 ) is cr-ni austenitic stainless steel has good oxidation resistance, corrosion resistance, due to high percentage of chromium and nickel, 310 / 310s has much better creep strength, can continue to work at high temperatures, has good resistance to high temperature.

310 Stainless Steel Pipe vs. 310S Stainless Steel Pipe: A Comprehensive Technical Comparison

1. Introduction

Stainless steel pipes, particularly grades 310 and 310S, are critical in high-temperature and corrosive environments. While both belong to the austenitic chromium-nickel alloy family, subtle differences in composition and performance dictate their suitability for specific industrial applications. This article explores the distinctions between stainless steel 310 pipe and stainless steel 310S pipe, supported by technical data and application examples.

310 Stainless Steel Pipe is austenitic stainless Steel pipe (24–26% Cr, 19–22% Ni, ≤0.25% C) compliant with ASTM A312 TP310/S31000. Designed for high-temperature applications (≤1150°C) with superior oxidation resistance, featuring tensile strength ≥515 MPa and carbon content ≤0.25%. Primarily used in non-welded heat-resistant components like industrial furnaces and heat treatment equipment.

310S Stainless Steel Pipe is austenitic stainless steel pipe (24-26% Cr, 19-22% Ni, ≤0.08% C) per ASTM A312 TP310S, optimized for oxidation/corrosion resistance in welded structures and high-temperature environments (≤1200°C). Applications include chemical processing pipes and furnace components.

2. Overview of 310 and 310S Stainless Steel Pipes

2.1 310 Stainless Steel Pipe

Stainless steel 310 pipe is a high-temperature alloy containing 24–26% chromium (Cr) and 19–22% nickel (Ni). Its elevated carbon content (≤0.25%) enhances strength but limits weldability. Key features include:

- Maximum Service Temperature: ≤1150°C (2100°F)

- Primary Standards: ASTM A312 TP310, ASME SA312

- Typical Applications: Industrial furnace parts, heat treatment equipment, non-welded components.

2.2 310S Stainless Steel Pipe

Stainless steel 310S pipe is a low-carbon variant (≤0.08% C) of grade 310, optimized for welded structures and prolonged high-temperature exposure. It retains the same Cr/Ni range but offers:

- Maximum Service Temperature: ≤1200°C (2192°F)

- Primary Standards: ASTM A312 TP310S, ASME SA312

- Typical Applications: Chemical processing piping, radiant tubes, welded furnace components.

3. Key Differences: 310 vs. 310S Stainless Steel Pipes

3.1 Chemical Composition

| Element | 310 Stainless Steel Pipe | 310S Stainless Steel Pipe |

|---|---|---|

| Chromium (Cr) | 24–26% | 24–26% |

| Nickel (Ni) | 19–22% | 19–22% |

| Carbon (C) | ≤0.25% | ≤0.08% |

| Manganese (Mn) | ≤2.0% | ≤2.0% |

| Silicon (Si) | ≤1.5% | ≤1.5% |

Analysis: The reduced carbon in 310S pipe minimizes carbide precipitation during welding, enhancing corrosion resistance in welded assemblies.

3.2 Mechanical Properties

| Property | 310 Stainless Steel Pipe | 310S Stainless Steel Pipe |

|---|---|---|

| Tensile Strength | ≥515 MPa (75 ksi) | ≥515 MPa (75 ksi) |

| Yield Strength | ≥205 MPa (30 ksi) | ≥205 MPa (30 ksi) |

| Elongation | ≥35% | ≥40% |

| Hardness | 95 HRB | 90 HRB |

Analysis: While both grades share similar tensile strength, 310S pipe exhibits marginally higher ductility (elongation) due to its lower carbon content.

3.3 Thermal and Corrosion Performance

| Parameter | 310 Stainless Steel Pipe | 310S Stainless Steel Pipe |

|---|---|---|

| Max Service Temp | ≤1150°C | ≤1200°C |

| Oxidation Resistance | Excellent (cyclic heating) | Superior (continuous heating) |

| Weldability | Moderate (risk of carbide precipitation) | Excellent (low-carbon design) |

Analysis: The 310S pipe outperforms grade 310 in continuous high-temperature service due to reduced carbon-induced embrittlement.

3.4 Physical Properties

| Property | 310 Stainless Steel Pipe | 310S Stainless Steel Pipe |

|---|---|---|

| Density | 8.0 g/cm³ | 8.0 g/cm³ |

| Thermal Conductivity | 14.2 W/m·K (100°C) | 14.2 W/m·K (100°C) |

| Electrical Resistivity | 0.78 µΩ·m | 0.78 µΩ·m |

Note: Identical density and thermal/electrical properties make both grades interchangeable in non-critical thermal applications.

4. Application-Specific Suitability

4.1 310 Stainless Steel Pipe Applications

- Non-welded furnace components (e.g., burner nozzles, trays).

- Heat treatment equipment requiring high strength.

- Lower-cost alternative where welding is not required.

4.2 310S Stainless Steel Pipe Applications

- Welded radiant tubes in petrochemical heaters.

- Continuous-operation kilns (e.g., ceramic, glass industries).

- Corrosive chemical processing systems with cyclic thermal loads.

5. Selection Guidelines

| Factor | Choose 310 Pipe | Choose 310S Pipe |

|---|---|---|

| Welding Required | Not recommended | Best choice |

| Budget Constraints | Lower cost | Higher cost (premium grade) |

| Operating Temp | ≤1150°C | ≤1200°C |

| Cyclic Heating | Suitable | Optimal |

6. Conclusion

Both stainless steel 310 pipe and stainless steel 310S pipe excel in extreme environments, but their differences in carbon content and weldability define their roles. For welded, high-temperature systems, 310S stainless steel pipe is the superior choice, while 310 stainless steel pipe remains cost-effective for non-welded, high-strength applications. Engineers must prioritize operating conditions, lifecycle costs, and fabrication methods when selecting between these grades.

KCM SPECIAL STEEL, 310/310S STAINLESS STEEL PIPE SUPPLIER RELATED PRODUCTS:

1. 310 / 310S STAINLESS STEEL PIPE FITTINGS :ELBOW, TEE, REDUCER, CAP, CROSS, STUB END.

2. 310 / 310S STAINLESS STEEL PIPE FLANGES: WELD NECK, SLIP ON, LAP JOINT, SOCKEL WELD, BLIND, THREAD

3. 310 / 310S STAINLESS STEEL VALVES: BALL VALVE, BUTTERFLY WALL, CHECK VALVE, ETC,

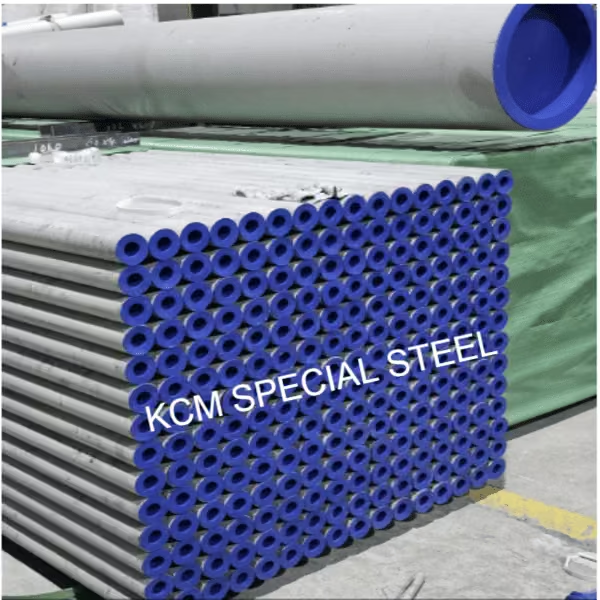

4. 310 / 310S STAINLESS STEEL SEAMLESS PIPES: SEAMLESS PIPE AND SEAMLESS TUBE AVAILABLE

5. 310 / 310S STAINLESS STEEL WELDED PIPES : ERW, EFW TYPES

6. 310 / 310S STAINLESS STEEL TUBES : SEAMLESS AND WELDED IS AVAILABLE IN STOCK.

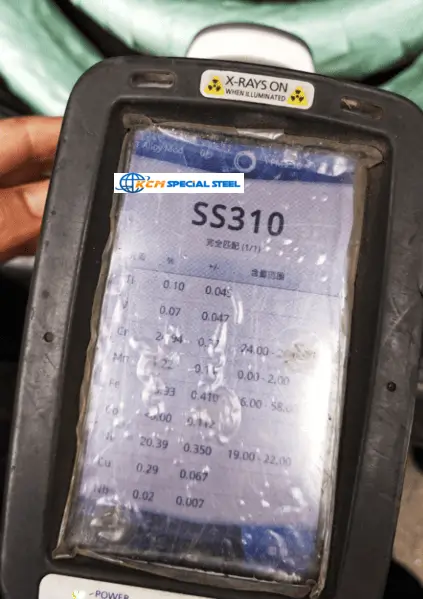

310S STAINLESS STEEL PIPE CHEMICAL COMPOSITON based on ASTM A312 TP310S Stainless Steel Pipe standards:

| Element | Composition Range (%) |

|---|---|

| Chromium (Cr) | 24.0 – 26.0 |

| Nickel (Ni) | 19.0 – 22.0 |

| Carbon (C) | ≤0.08 |

| Manganese (Mn) | ≤2.0 |

| Silicon (Si) | ≤1.5 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.03 |

| Nitrogen (N) | ≤0.11 |

| Iron (Fe) | Balance |

Key Notes:

- Low Carbon Advantage: The reduced carbon content (≤0.08%) in 310S minimizes carbide precipitation during welding, enhancing corrosion resistance.

- Balanced Cr/Ni Ratio: High chromium (24-26%) and nickel (19-22%) ensure superior oxidation resistance up to 1200°C.

- Trace Elements: Controlled levels of P, S, and N optimize weldability and high-temperature stability.

This composition aligns with ASTM A312 TP310S specifications for welded high-temperature piping systems.

PMI Tested Chemical Compositon:

310/310S STAINLESS STEEL PIPE SUPPLIER AND MANUFACTURER IN CHINA,contact us to get discount price and high quality stainless steel 310 tube.

Chemical composition of 310 Stainless Steel Pipe based on ASTM A312 TP310 Stainless Steel Pipe standards:

| Element | Composition Range (%) |

|---|---|

| Chromium (Cr) | 24.0 – 26.0 |

| Nickel (Ni) | 19.0 – 22.0 |

| Carbon (C) | ≤0.25 |

| Manganese (Mn) | ≤2.0 |

| Silicon (Si) | ≤1.5 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.03 |

| Nitrogen (N) | ≤0.11 |

| Iron (Fe) | Balance |

Key Notes:

- Higher Carbon Content: The carbon in 310 stainless steel pipe (≤0.25%) improves strength but increases susceptibility to carbide precipitation during welding, limiting its use in welded high-temperature applications.

- Cr/Ni Balance: Matches 310S in chromium and nickel content, ensuring excellent oxidation resistance up to 1150°C (2100°F).

- Trace Elements: Controlled sulfur and phosphorus levels enhance machinability and corrosion resistance.

This composition aligns with ASTM A312 TP310 specifications, ideal for non-welded components requiring high strength and moderate oxidation resistance.

310S / 310 STAINLESS STEEL PIPE SUPPLIER Mechanical performance

Tensile strength (б) b (Mpa) : ≥520

Yield strength (sigma s) (Mpa) : ≥205

Area reduction (ψ) : ≥50%

the Elongation (δ) : ≥40 %

HB : ≤187

Melting point : 1398 ℃ ~ 1454 ℃

stand temperatures: up to 1150 ℃.

310 / TP310S STAINLESS STEEL PIPE SUPPLIER Heat treatment

Tempering: 180 ~ 200

Annealing status: less than 207HB,

the diameter of the indentation is ≥ 4.20 mm

Quenching: 62 HRC

310S STAINLESS STEEL PIPE SUPPLIER features:

Due to the high content of nickel (Ni) and chromium (Cr), it has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. High temperature resistant steel pipes are specially used for manufacturing electric furnace tubes and other applications. After increasing the carbon content in austenitic stainless steel, its strength is improved due to its solid solution strengthening effect. The chemical composition characteristics of austenitic stainless steel are based on chromium and nickel, with the addition of elements such as molybdenum, tungsten, niobium, and titanium. Due to its face centered cubic structure, it has high strength and creep strength at high temperatures.

310S stainless steel pipe function

Improve the brittle properties of carbon tool steel to extend the lifespan of the tool. Vacuum degassing refined steel with stable quality. Good hardenability, oil cold hardening (less cracking and deformation), good toughness and wear resistance, and durable tools.

310s stainless steel pipe is divided into industrial and subsurface

A type of stainless steel tube with a flat surface of 310s, which is treated only by the surface. In addition to the normal 310s stainless steel tubes. The solution is as follows:

To make a working liquid, a 1:1 ratio of sublight to water. Under normal temperature or heating electrolyte to 40-50 degrees, hang in the cathode lead plate or stainless steel plate, electrolytic polishing workpiece is fixed in the anode, and then adjust the voltage at around 5 v, polishing 3-5 minutes remove artifacts. Finished subphotoelectrolytic technology.

Technical process: chemical oil removal, rust removal, water washing, electrolytic sublight, water wash, and water wash

SS310/TP310S STAINLESS STEEL PIPE SUPPLIER AVAILABLE SIZES IN STOCK

ASTM A213/A312 TP 310/310s stainless steel pipe supplier & manufacturer in china, contact us now to get discout price and high quality stainless steel pipe 310 Pipe.

| INCH | inch sizc (ID) | OD | WT STANDARD | ||||||||||||||

| SCH 5s | SCH 10S | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | STD | XS | XXS | |||

| 1/8 | DN6 | 10.3 | – | 1.24 | – | – | – | 1.73 | – | 2.42 | – | – | – | – | 1.73 | 2.41 | – |

| 1/4 | DN8 | 13.7 | – | 1.65 | – | – | – | 2.24 | – | 3.02 | – | – | – | – | 2.24 | 3.02 | – |

| 3/8 | DN10 | 17.1 | – | 1.65 | – | – | – | 2.31 | – | 3.2 | – | – | – | – | 2.31 | 3.2 | – |

| 1/2 | DN15 | 21.3 | 1.65 | 2.11 | – | – | – | 2.77 | – | 3.73 | – | – | – | 4.78 | 2.77 | 3.73 | 7.47 |

| 3/4 | DN20 | 26.7 | 1.65 | 2.11 | – | – | – | 2.87 | – | 3.91 | – | – | – | 5.56 | 2.87 | 3.91 | 7.82 |

| 1 | DN25 | 33.4 | 1.65 | 2.77 | – | – | – | 3.38 | – | 4.55 | – | – | – | 6.35 | 3.38 | 4.55 | 9.09 |

| 1.1/4 | DN32 | 42.2 | 1.65 | 2.77 | – | – | – | 3.56 | – | 4.85 | – | – | – | 6.35 | 3.58 | 4.85 | 9.7 |

| 1.1/2 | DN40 | 48.3 | 1.65 | 2.77 | – | – | – | 3.68 | – | 5.05 | – | – | – | 7.14 | 3.68 | 5.08 | 10.15 |

| 2 | DN50 | 60.3 | 1.65 | 2.77 | – | – | – | 3.91 | – | 5.54 | – | – | – | 8.74 | 3.91 | 5.54 | 11.07 |

| 2.1/2 | DN65 | 73 | 2.11 | 3.05 | – | – | – | 5.16 | – | 7.01 | – | – | – | 9.53 | 5.16 | 7.01 | 14.02 |

| 3 | DN80 | 88.9 | 2.11 | 3.05 | – | , – | – | 5.49 | – | 7.62 | – | – | – | 11.13 | 5.49 | 7.52 | 15.24 |

| 3.1/2 | DN90 | 101.6 | 2.11 | 3.05 | – | – | – | 5.74 | – | 8.08 | – | – | – | – | 5.74 | 8.08 | – |

| 4 | 114.3 | 2.11 | 3.05 | – | – | – | 6.02 | – | 8.58 | – | 11.13 | – | 13.49 | 6.02 | 8.56 | 17.12 | |

| 5 | DN125 | 141.3 | 2.77 | 3.4 | – | – | – | 6.55 | – | 9.53 | – | 12.7 | – | 15.88 | 6.55 | 9.53 | 18.05 |

| 6 | DN150 | 168.3 | 2.77 | 3.4 | – | – | – | 7.11 | – | 10.97 | – | 14.27 | – | 18.26 | 7.11 | 10.97 | 21.95 |

| 8 | DN200 | 219.1 | 2.77 | 3.76 | – | 6.35 | 7.04 | 8.18 | 10.31 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 8.18 | 12.7 | 22.23 |

| 10 | DN250 | 273.1 | 3.4 | 4.19 | – | 6.35 | 7.8 | 9.27 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 9.27 | 12.7 | 25.4 |

| 12 | DN300 | 323.9 | 3.96 | 4.57 | – | 6.35 | 8.38 | 10.31 | 14.27 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 9.35 | 12.7 | 25.4 |

| 14 | DN350 | 355.5 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 11.13 | 15.09 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | 9.53 | 12.7 | – |

| 16 | DN400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 12.7 | 16.66 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | 9.53 | 12.7 | – |

| 18 | DN450 | 457 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 14.27 | 19.05 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | 9.53 | 12.7 | – |

| 20 | DN500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 15.09 | 20.62 | 26.19 | 32.54 | 38.1 | 44.45 | , 50.01 | 9.53 | 12.7 | – |

| 22 | DN550 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | – | 22.23 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | 9.53 | 12.7 | – |

| 24 | DN600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 24.61 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | 9.53 | 12.7 | – |

| 26 | DN650 | 660 | – | – | 7.92 | 12.7 | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 28 | DN700 | 711 | – | – | 7.92 | 12.7 | 15.88 | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 30 | DN750 | 762 | 6.35 | 7.92 | 7.92 | 12.7 | 15.88 | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 32 | DN800 | 813 | – | – | 7.92 | 12.7 | 15.88 | 17.48 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 34 | DN850 | 864 | – | – | 7.92 | 12.7 | 15.88 | 17.48 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 36 | DN900 | 914 | – | – | 7.92 | 12.7 | 15.88 | 19.05 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 38 | DN950 | 965 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 40 | DN1000 | 1015 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 42 | DN1050 | 1067 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 44 | DN1100 | 1118 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 46 | DN1150 | 1188 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 48 | DN1200 | 1219 | – | – | – | – | – | – | – | – | – | – | – | – | |||

310 / 310S Stainless Steel Pipe: Customer Applications & Feedback

1. Oil & Gas Industry

- Application:

- 310S pipes are widely used in furnace tubes, heating systems, and catalytic cracking units due to their exceptional oxidation resistance at temperatures up to 1200°C. These pipes ensure safe operation and extended equipment lifespan in refineries and petrochemical plants.

- Customer Feedback:

- “TP310S pipes significantly reduced downtime in our high-temperature reactors, maintaining structural integrity even under cyclic thermal stress.”

2. Chemical Processing

- Application:

- Stainless steel 310 pipes are deployed in fertilizer production equipment and acid-resistant reactors, where they resist sulfur and chemical corrosion.

- Customer Feedback:

- “Switching to 310S pipes eliminated premature failures in our sulfuric acid processing units, cutting maintenance costs by 30%.”

3. Power Generation

- Application:

- 310S seamless pipes are critical in boiler systems and gas turbine exhaust ducts, handling high-pressure steam and corrosive flue gases.

- Customer Feedback:

- “TP310S pipes delivered consistent performance in our coal-fired power plant boilers, with no signs of scaling after 18 months of operation.”

4. Pharmaceutical & Food Industries

- Application:

- 310S stainless steel tubes are used in sterile processing pipelines and cleanroom HVAC systems, meeting strict hygiene and oxidation resistance requirements.

- Customer Feedback:

- “The smooth surface finish of 310S pipes minimized bacterial buildup, ensuring compliance with FDA standards.”

5. High-Temperature Manufacturing

- Application:

- 310 pipes are utilized in glass kilns, ceramic furnaces, and heat treatment equipment, where they withstand prolonged exposure to 1100°C+ environments.

- Customer Feedback:

- “TP310 pipes in our ceramic kiln showed no deformation after 2 years, outperforming previous materials like Inconel.”

Key Customer Takeaways

- Performance:

- Both grades excel in extreme heat, but 310S is preferred for welded systems due to its low carbon content and reduced intergranular corrosion risks.

- Cost Efficiency:

- Clients report 20–35% longer service life compared to 304/316 pipes in similar conditions.

- Supplier Reliability:

- KCM SPECIAL STEEL’s ASTM/ASME-certified TP310S pipes are praised for on-time delivery and custom sizing (e.g., DN6–DN400, Sch40).

For technical specifications or case studies, contact KCM SPECIAL STEEL.

310 / 310S Stainless Steel Pipe Supplier & Manufacturer FAQ – KCM SPECIAL STEEL

1. What is the density of ss310 and ss310s pipes?

- Both ss310 pipe and ss310s pipe have a density of 7.98 g/cm³, ensuring lightweight yet durable performance in extreme heat.

2. Why choose ss310s stainless steel pipe for welding?

- TP310S Stainless Steel Pipe: Low carbon reduces intergranular corrosion risks, eliminating post-weld heat treatment.

- TP310 Stainless Steel Pipe: Requires annealing after welding due to higher carbon content.

3. What industries use 310 and 310s stainless steel pipes?

- SS310 Pipe:

- Power plants (boiler components).

- Automotive exhaust systems.

- SS310S Pipe:

- Petrochemical heaters (resists sulfur corrosion).

- Aerospace and nuclear industries.

4. Do TP310 and TP310s stainless steel pipes comply with global standards?

- Standards:

- TP310 SS Pipe: ASTM A312, ASME SA312.

- TP310S SS Pipe: EN 10028-7, ISO 15510.

- Certifications: KCMSS pipes are ISO 9001 certified.

5. What are the mechanical properties of 310/310s stainless steel pipes?

| Property | 310 Stainless Steel Pipe | 310S Stainless Steel Pipe |

|---|---|---|

| Tensile Strength | ≥515 MPa | ≥515 MPa |

| Yield Strength | ≥205 MPa | ≥205 MPa |

| Elongation | ≥35% | ≥40% |

6. Where to Buy 310 / 310S Stainless Steel Pipe In CHINA?

KCM SPECIAL STEEL CO.,LTD

- Expertise: Over 20 years in manufacturing TP310 ss pipe and TP310s ss pipe.

- Customization:

- Sizes: 1/8″ to 60″ OD.

- Finishes: Annealed, pickled, or polished.

- Type: Seamless And Welded.

- Global Supply: Fast delivery to Europe, Asia, and North America.

Contact KCM SPECIAL STEEL for premium-grade ss 310 pipe and ss 310s pipe solutions.

Conclusion: 310/310S Stainless Steel Pipe

Material Superiority

High-Temperature Resistance:

- 310/310S pipes demonstrate exceptional oxidation resistance at temperatures up to 1200°C, with continuous service capabilities up to 1150°C. Their high chromium (24–26%) and nickel (19–22%) content ensures stability in cyclic thermal environments such as furnaces and boilers.

- The low carbon content in 310S minimizes intergranular corrosion risks, making it ideal for welded systems.

Corrosion Resistance:

- Resistant to sulfur, acids, chlorides, and alkalis, these pipes are widely used in chemical processing, oil refineries, and environments with corrosive flue gases.

Mechanical Strength:

- Tensile strength ≥515 MPa and yield strength ≥205 MPa enable reliable performance under high-pressure and high-stress conditions.

Key Industrial Applications

- Oil & Gas:

- Used in catalytic cracking units, furnace tubes, and high-temperature reactors due to oxidation resistance and structural integrity.

- Power Generation:

- Critical for boiler systems, gas turbine exhaust ducts, and heat exchangers handling high-pressure steam.

- Chemical & Pharmaceutical:

- Deployed in acid-resistant reactors, sterile pipelines, and cleanroom HVAC systems, meeting FDA hygiene standards.

- High-Temperature Manufacturing:

- Applied in glass/ceramic kilns and heat treatment equipment, outperforming materials like Inconel in deformation resistance.

Economic & Operational Benefits

- Extended Service Life:

- Provides 20–35% longer lifespan compared to 304/316 stainless steel in extreme conditions, reducing maintenance costs.

- Cost Efficiency:

- Reduced downtime and replacement frequency enhance operational efficiency in industries like petrochemicals and power plants.

Supplier Considerations

- Quality:

- ASTM A312, ASME SA312, and EN 10028-7 ensure compliance with global quality standards.

- Customization:

- Opt for suppliers offering tailored sizes (DN6–DN2000), seamless/polished finishes, and traceable material testing.

Final Recommendation:

310/310S stainless steel pipes are indispensable for high-temperature and corrosive environments. Prioritize certified supplier KCM SPECIAL STEEL for guaranteed performance and durability.