- Home

- Products

- STAINLESS STEEL PIPE AND FITTINGS

- Stainless Steel Pipe Suppliers T4 Tube

- STAINLESS STEEL PIPE FITTINGS

- 304 Stainless Steel Pipe

- 304L Stainless Steel Pipe

- 321 Stainless Steel Pipe

- 316 Stainless Steel Tubing Pipe

- 316L Stainless Steel Pipe

- 316Ti Stainless Steel Pipe

- 317L Stainless Steel Pipe

- TP347H STAINLESS STEEL PIPE

- 310 / 310S Stainless Steel Pipe Suppliers

- 904L Stainless Steel Pipe

- 253MA Stainless Steel Pipe UNS S30815 1.4835

- Stainless Steel Square Tube

- AL-6XN Stainless Steel Pipe UNS N08367 1.4529

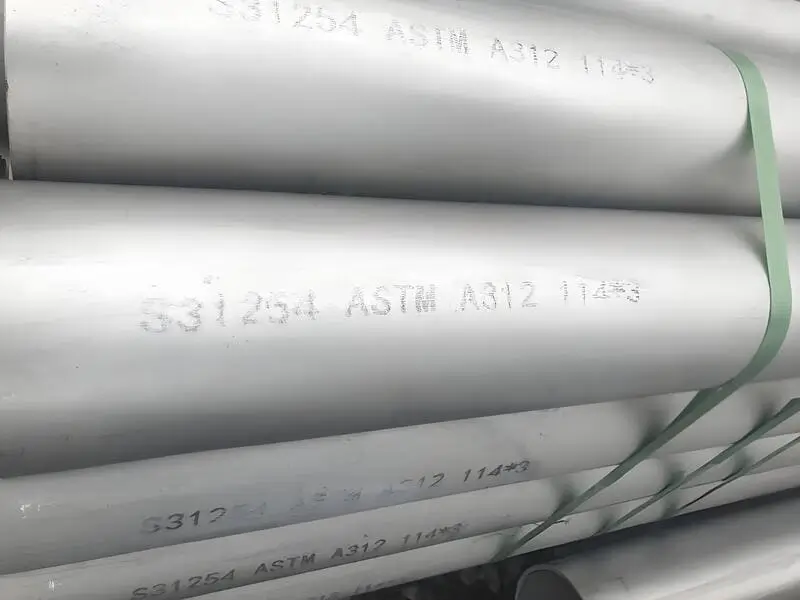

- 254SMO Stainless Steel Pipe UNS S31254 1.4547

- DUPLEX STAINLESS STEEL PIPE AND FITTINGS

- Duplex 2205 Stainless Steel Pipe

- SUPER DUPLEX 2507 STAINLESS STEEL PIPE

- Astm A790 / A789 UNS S31803 Duplex Pipe Tube

- ASTM A790 UNS S32750 Super Duplex Pipe/Tube

- ASTM A815 UNS S31803 Duplex Steel Pipe Fittings / S32205 Butt Weld Fittings / SAF 2205 Duplex Pipe Fittings

- ASTM A928 UNS S31803 EFW Pipe / SA928 S32205 Welded Duplex Pipes

- ASTM A928 UNS S32750 EFW Super Duplex Pipe / 2507 Welded Pipe 1.4410

- ASTM A815 UNS S32750 Super Duplex Steel Pipe Fittings / 2507 1.4410 F53

- Duplex 2304 Stainless Steel Pipe

- Duplex S32760 Stainless Steel Pipe

- NICKEL ALLOY PIPE AND FITTINGS

- Nickel Alloy Hastelloy C-276 Pipe and Fittings UNS N10276 2.4819

- Alloy 200/Nickel 200 Pipe and Fittings UNS N02200 2.4066

- Alloy 201/Nickel 201 Pipe and Fittings UNS N02201 2.4068

- Nickel Alloy Monel 400 Pipes And Fittings

- Nickel Alloy Inconel 600 Pipes And Fittings

- Nickel Alloy Inconel 601 Pipes And Fittings

- Nickel Alloy Inconel 625 Pipes And Fittings

- Nickel Alloy Inconel 718 Pipes And Fittings

- Nickel Alloy Incoloy 800H Pipes And Fittings

- Nickel Alloy INCOLOY 800HT Pipes and Fittings

- Nickel Alloy Incoloy 825 Pipes And Fittings

- ASTM A453 Grade 660 A/B/C/D Stainless Steel: Plate, Sheet, Bar, Rod, Forgings

- STAINLESS STEEL PIPE FLANGES

- STAINLESS STEEL VALVES

- CARBON STEEL PIPE AND FITTINGS

- STAINLESS STEEL PIPE AND FITTINGS

- STANDARDS

- STAINLESS STEEL STORE

- ABOUT

- CONTACT

company news

05

Dec

What is S31254 Stainless Steel? This article clarifies why S31254 is not duplex stainless steel, explores its true classification as a super austenitic stainless steel, compares it with genuine duplex grades, lists its common alternative...

18

Aug

Introduction- 316L Stainless Steel Pipe and Fittings to Africa 316L Stainless Steel Pipe and Fittings to Africa - Custom 6-inch threaded solutions for Mauritanian water projects, 100% Perfect & ISO-certified. KCMSS delivers durability & cost...

25

Jun

304 and 316L Stainless Steel Seamless Pipe to Indonesia: Premium Stock for Immediate Export 1. Introduction: Meeting Indonesia’s Industrial DemandIndonesia’s rapidly expanding infrastructure and manufacturing sectors require reliable supplies of high-performance stainless steel piping. Specifically,...

02

Jun

Successful Implementation of 1.4462 Duplex Steel Flange to Qatar's Desalination Infrastructure IntroductionThis comprehensive case study examines the exceptional performance of UNS S31803 (1.4462) duplex stainless steel flanges in one of Qatar's largest seawater desalination plants....

12

May

304 Stainless Steel Pipe to Malaysia: Comprehensive Supply Guide for Immediate Procurement KCM Special Steel Delivers ASTM A312 TP304 Stainless Steel Pipe to Malaysia in Bulk Stock – SCH40, 3/4''–8'', Around 6M Random Length. 304 Stainless...

29

Apr

This case study highlights the rapid production of 2,000 custom 316 stainless steel 180° elbows for a luxury UAE hotel HVAC project. Key achievements include:

15-day end-to-end delivery via optimized workflows and H13 tool steel mold development (7-day turnaround).

Precision manufacturing with ±0.1mm wall thickness control and Ra ≤0.8μm mirror finish.

Rigorous quality compliance: 90 bar hydrostatic testing, 480-hour salt spray resistance, and 100% CMM inspection.

Client success: Zero post-installation maintenance and 12% HVAC efficiency gain, leading to repeat orders.

Core innovations: Seamless cold-forming technology, electrolytic polishing, and agile logistics for GCC-region projects.

26

Apr

KCM SPECIAL STEEL customized three non-standard thick-walled 304 stainless steel tubes (242×31×6000mm) for a Brazilian engineering firm, delivering within 15 days. The client praised precise tolerances (±0.5mm), high density (7.97g/cm³), and timely delivery, underscoring KCM’s expertise in large-diameter, heavy-walled pipe solutions and global supply chain efficiency. Keywords: thick-walled stainless steel tube to Brazil, large diameter stainless steel pipe, heavy-walled stainless steel tube.

24

Apr

KCM SPECIAL STEEL successfully exported 5” SCH STD Duplex 2205 stainless steel pipes (UNS S31803) to a Saudi trading company. Faced with logistics challenges due to unavailable 40ft LCL containers for 6m pipes, KCM proposed precision-cutting the pipes to 3m for 20ft LCL shipping to Dammam Port. Post-delivery, the client praised the pipes’ excellent quality, precise chemical composition (Cr: 22-23%, Mo: 3-3.5%), dimensional accuracy (±0.5mm), and controlled density variance (1-2%). The case highlights KCM’s adaptability, fast delivery, and expertise in OEM customization. With robust stock availability and ISO-certified quality, KCM reinforces its reliability for global clients in demanding industries like oil and gas.

21

Apr

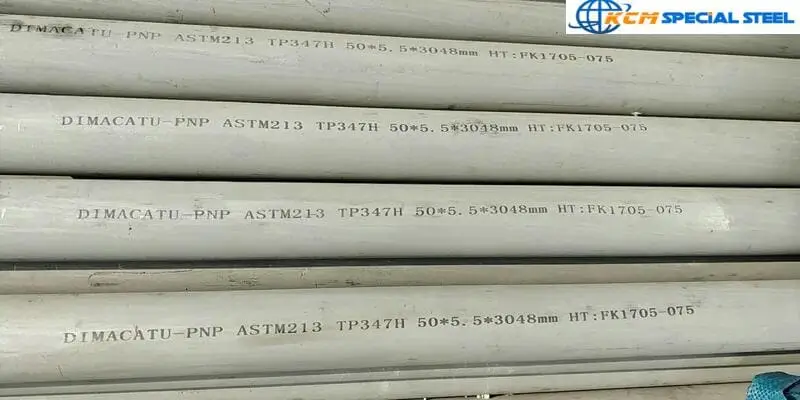

KCM SPECIAL STEEL delivered 69pcs non-standard ASTM A213 TP347H stainless steel pipes to a Mexican industrial client, overcoming a 30-day delivery challenge. To meet strict requirements—including , specialized dimensions (OD: 48.6/50/50.4/54 mm, wall thickness: 5.5/5.9/8.2 mm), and high tensile strength (≥515 MPa)—KCM optimized cold-drawing and heat treatment processes. Rigorous quality protocols, such as ultrasonic testing (ASTM E213) and tensile analysis (ASTM E8), ensured compliance with performance benchmarks (achieved 530 MPa tensile strength, density variation <2%). The client confirmed exceptional performance in high-temperature/pressure environments, highlighting KCM’s global expertise in non-standard manufacturing and agile delivery.Key Highlights Custom Non-Standardization: Precise control of density, dimensions, and strength for industrial specifications. Full-Cycle Quality Control: ASTM-compliant testing across production stages. 30-Day Agile Delivery: Cross-department collaboration ensured on-time completion of urgent orders. This project reinforces KCM’s leadership in delivering high-performance, custom-engineered solutions for critical industrial applications.

17

Apr

This customer case study highlights the successful application of 316Ti stainless steel pipes (EN 1.4571) supplied by KCM SPECIAL STEEL for low-pressure air transport (≤2 bar gauge pressure) in a European sewage treatment plant. Faced with frequent corrosion failures in carbon steel pipes due to moisture, chlorides, and hydrogen sulfide, the plant sought a durable, cost-effective solution. KCM delivered 316Ti pipes stabilized with titanium to prevent weld decay, ensuring compliance with EN 1.4571 standards and 2% optimized alloy density for enhanced performance.

Key outcomes include zero leaks/corrosion after 24 months, €48,000/year maintenance savings, and full compliance with third-party inspections (PMI, dimensional checks, hydrostatic tests). The project underscores 316Ti’s superiority in aggressive environments, offering 25–30% lower lifecycle costs than 316L. KCM’s precision manufacturing, rigorous quality control, and certified logistics ensured seamless installation and long-term reliability.

This case validates 316Ti stainless steel as an ideal choice for cost-sensitive, corrosive applications, aligning with EU sustainability goals through recyclability and reduced downtime.

Keywords: 316Ti stainless steel pipe, EN 1.4571, low-pressure air transport, sewage treatment plant, third-party inspection, lifecycle cost savings.

12