Duplex Stainless Steel Pipe/Tubes/Tubing for Chemical Industrial Applications

Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical Industry

Duplex stainless steel pipes (DSS pipes), tubes, and tubing have become indispensable in the chemical industry due to their unique combination of high strength, exceptional corrosion resistance, and cost-effectiveness. These materials, characterized by a balanced microstructure of austenite and ferrite phases, exhibit superior performance in harsh environments involving high temperatures, pressures, and corrosive media. Below is a comprehensive analysis of their applications, supported by technical data and industry case studies.

1. Chemical Reactors-Duplex Stainless Steel Tube for Chemical Industrial Applications

Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical Industry Key Components:

- Agitator shafts, cooling coils, and reactor linings in high-pressure reactors.

- Performance Advantages:

- High yield strength (2–3× higher than standard austenitic grades like 316L) ensures structural integrity under extreme pressure.

- Resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) in acidic/chloride-rich environments.

Case Study:

In urea production, CO₂ compressor cooling systems using 316L stainless steel pipe failed within one month due to SCC, while duplex stainless steel tubes (e.g., 2205 duplex pipe) lasted over five years.

2. Pipeline Systems-Duplex Stainless Steel Pipe for Chemical Industrial Applications

Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical Industry-Applications:

- Transporting acids (HCl, H₂SO₄), alkalis (NaOH), and organic solvents.

- Material Selection:

Grade PREN* Key Features Typical Use Cases S32205 35 Cost-effective, moderate corrosion resistance Chlor-alkali plants, brine lines S32750 42 Superior chloride resistance Offshore pipelines, sulfuric acid transport *PREN = Pitting Resistance Equivalent Number (Cr + 3.3Mo + 16N)

Advantages:

- Reduced downtime due to extended service life and leak prevention in corrosive media.

3. Heat Exchangers-Duplex Stainless Steel Tubing For Chemical Industrial Applications

Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical Industry-Design Requirements:

- Thermal stability (operating temperatures up to 300°C) and corrosion resistance in cooling fluids (e.g., seawater, acidic condensates).

- Material Performance:

- High thermal conductivity (15–20 W/m·K) and low thermal expansion (13 μm/m·K) minimize thermal stress.

- Resistance to ammonium chloride deposits in refinery overhead condensers.

Applications:

- Shell-and-tube heat exchangers in petroleum refining and fertilizer production.

4. Distillation Columns and Towers

Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical Industry-Critical Components:

- Tray supports, packing grids, and reactor effluent air coolers (REACs).

- Case Example:

- Zhenhai Refining & Chemical Company (China) uses DSS tubes in atmospheric distillation tower linings, achieving over 20 years of service in HCl-rich environments.

Material Benefits:

- Reduced wall thickness (30–50% thinner than carbon steel) lowers material costs without compromising strength.

5. Storage Tanks and Vessels

Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical Industry-Applications:

- Acid/alkali storage tanks, solvent containers, and pressure vessels.

- Design Features:

- DSS tubing (e.g., Duplex 2205 Tube) provides leak-proof welding and resistance to sulfide stress cracking in sour gas environments.

Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical Industry-Comparison of DSS Grades for Storage Systems:

| Property | S31803 (2205) | S32750 (2507) |

|---|---|---|

| Yield Strength (MPa) | 450 | 550 |

| PREN | 35 | 42 |

| Max Operating Temp. | 250°C | 300°C |

| Cost Index | 1.0 | 1.8 |

6. Emerging Applications

Applications of Duplex Stainless Steel Pipes/Tubes in the Chemical Industry

- Wastewater treatment: Duplex stainless steel tubes resist bio-corrosion in chlorinated water systems.

- Hydrogen storage: High-pressure hydrogen compatibility due to low hydrogen embrittlement susceptibility.

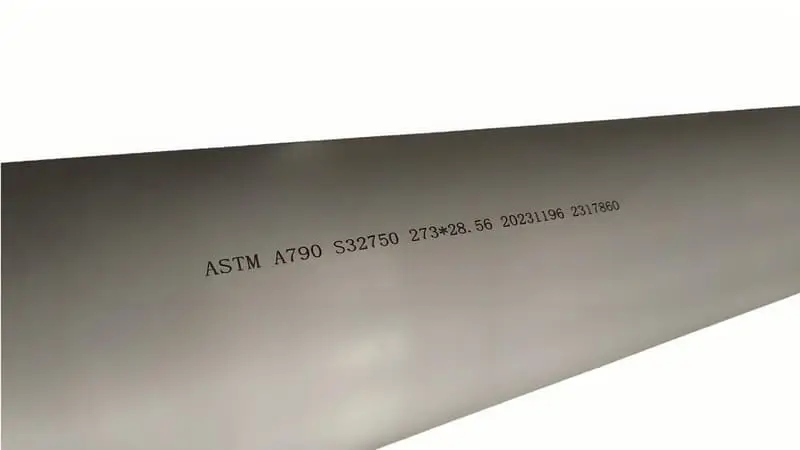

ASTM A928/ASTM A789/ASTM A790 Duplex Stainless Steel Pipe/Tube Standards Free Read Online:

ASTM A928.pdf

ASTM A928 Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded with Addition Of Filler Metal

ASTM A789.pdf

ASTM A789 Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

ASTM A790.pdf

ASTM A790 Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

ASTM A790.pdf

ASTM A790/A790M-08a specifies requirements for seamless/welded duplex stainless steel pipes (e.g., UNS S31803) in corrosive environments, permitting NDT methods like ultrasonic testing as hydrostatic test alternatives, with dual unit systems (SI & inch-pound).

Technical Advantages of Duplex Stainless Steel Tubing

- Density: 7.7–7.9 g/cm³ (1–2% lighter than nickel alloys).

- Fatigue resistance: 50% higher than austenitic grades under cyclic loading.

Conclusion

Duplex stainless steel pipes and tubes have revolutionized chemical equipment design by offering a balance of mechanical robustness and corrosion resistance. From reactors to pipelines, their adaptability ensures safer, longer-lasting operations in one of the most demanding industrial sectors. Continued advancements in grades like S32750 and S31803 will further expand their role in sustainable chemical processing.