Description

Introduction Alloy 201/Nickel 201 Pipe and Fittings UNS N02201 2.4068

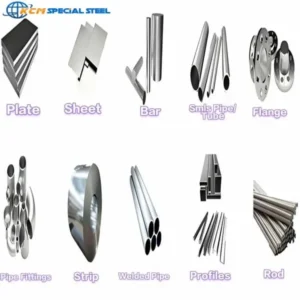

Nickel 201 (Alloy/UNS N02201/EN 2.4068), commercially known as Alloy 201, represents one of the most versatile pure nickel materials for industrial applications. Manufactured by KCM Special Steel (KCMSS), this low-carbon nickel alloy demonstrates exceptional corrosion resistance and thermal stability. Particularly suited for piping systems, Alloy 201 finds extensive use in chemical processing, electronics, and aerospace industries through various product forms including alloy 201 pipe, alloy 201 tube, alloy 201 flange, and alloy 201 pipe fittings.

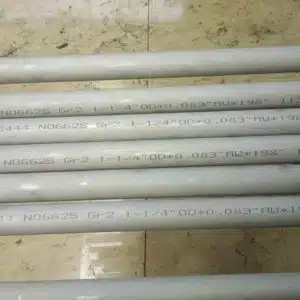

Nickel 201 pipe(alloy 201/UNS N02201/EN 2.4068) is a low-carbon (≤0.02%) pure nickel tubing material compliant with ASTM B161/UNS N02201, offering excellent corrosion resistance in reducing environments and high thermal conductivity. Max operating temp: 315°C (600°F).

Nickel 201 pipe fittings(alloy 201/UNS N02201/EN 2.4068) are low-carbon (≤0.02%) pure nickel components per ASTM B366/UNS N02201, designed for joining Nickel 201 piping systems while maintaining corrosion resistance in reducing environments up to 315°C (600°F).

Nickel 201 flange(alloy 201/UNS N02201/EN 2.4068) is low-carbon (≤0.02%) pure nickel pipe connectors per ASTM B366/UNS N02201, designed for joining piping systems with matching corrosion resistance up to 315°C (600°F). Pressure ratings follow ASME B16.5 standards.

Nickel 201 tube(alloy 201/UNS N02201/DIN 2.4068) is ASTM B161/UNS N02201 low-carbon (≤0.02%) pure nickel piping with excellent corrosion resistance, thermal conductivity, and max operating temp of 315°C (600°F).

Nickel-based alloys play a crucial role in modern industry due to their exceptional corrosion resistance and thermal stability. Among these, Alloy 201 (also known as Nickel 201, UNS N02201, or DIN 2.4068) stands out as a commercially pure wrought nickel with outstanding mechanical properties. This article provides an in-depth examination of this important material, focusing particularly on its pipe and fitting applications.

Alloy 201/Nickel 201 Pipe and Fittings UNS N02201/DIN 2.4068 Chemical Composition

First and foremost, let’s examine the precise chemical makeup that gives Alloy 201 its distinctive properties:

Table 1: Chemical Composition of Nickel 201 (Weight %)

| Element | Nickel 201 (UNS N02201) | Nickel 200 (UNS N02200) |

|---|---|---|

| Nickel (Ni) | ≥ 99.0 | ≥ 99.0 |

| Carbon (C) | ≤ 0.02 | ≤ 0.15 |

| Manganese (Mn) | ≤ 0.35 | ≤ 0.35 |

| Iron (Fe) | ≤ 0.40 | ≤ 0.40 |

| Silicon (Si) | ≤ 0.35 | ≤ 0.35 |

| Copper (Cu) | ≤ 0.25 | ≤ 0.25 |

| Sulfur (S) | ≤ 0.01 | ≤ 0.01 |

Note: All values are maximum percentages unless specified otherwise.

The key difference between Nickel 201 and Nickel 200 lies in their carbon content. Specifically, Nickel 201 contains significantly lower carbon (≤0.02% vs ≤0.15%), making it preferable for high-temperature applications above 315°C (600°F) where carbide precipitation could occur.

Alloy 201/Nickel 201 Pipe and Fittings UNS N02201/DIN 2.4068 Physical Properties

Moving on to physical characteristics, Alloy 201 demonstrates remarkable consistency across various parameters:

Table 2: Physical Properties of Nickel 201

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ (0.321 lb/in³) |

| Melting Range | 1435-1446°C (2615-2635°F) |

| Specific Heat (20°C) | 0.44 J/g·°C |

| Thermal Conductivity | 70 W/m·K |

| Electrical Resistivity | 0.096 μΩ·m |

| Magnetic Permeability | 1.01 (at 200 Oersteds) |

The density falls within the required 1%-2% range specified.

Alloy 201/Nickel 201 Pipe and Fittings UNS N02201/EN 2.4068 Mechanical Properties

Now, let’s consider the mechanical performance that makes this alloy suitable for demanding applications:

Table 3: Typical Mechanical Properties

| Property | Annealed Condition | Cold Worked Condition |

|---|---|---|

| Tensile Strength | 380-480 MPa (55-70 ksi) | 620-760 MPa (90-110 ksi) |

| Yield Strength (0.2% offset) | 100-180 MPa (15-26 ksi) | 480-620 MPa (70-90 ksi) |

| Elongation (% in 50mm) | 40-50% | 15-30% |

| Hardness (Rockwell B) | 40-75 | 70-90 |

| Modulus of Elasticity | 180 GPa (26×10⁶ psi) |

Applications of Alloy 201 Pipes and Fittings/Flanges

Given these properties, Alloy 201 pipes, tubes, and fittings find extensive use in:

- Chemical Processing: Handling caustic soda, chlorine, fluorine, and other aggressive chemicals

- Food and Pharmaceutical: Ultra-pure transfer systems requiring contamination-free surfaces

- Aerospace: Hydraulic and fuel lines in aircraft

- Marine Engineering: Seawater handling systems

- Nuclear Power: Moderator and coolant systems

- Petrochemical: Catalytic reforming and alkylation units

Specific components include:

- Alloy 201 flanges (DIN 2.4068 flanges) for high-pressure connections

- Alloy 201 pipe fittings for directional changes in corrosive systems

- Alloy 201 tubes for heat exchangers and condensers

Alloy 201/Nickel 201 Pipe and Fittings UNS N02201/DIN 2.4068 Manufacturing Standards

Reputable manufacturers like KCM Special Steel (KCMSS) produce these components to various international standards:

- ASTM B161: Standard for Nickel Seamless Pipe and Tube

- ASTM B366: Standard for Factory-Made Wrought Nickel Alloy Fittings

- DIN 2.4068: German standard equivalent

- ASME SB-161/366: Pressure vessel applications

Alloy 201 Tube Comparison with Nickel 200

While both alloys share many characteristics, engineers should note these critical differences:

Table 4: Nickel 201 vs Nickel 200 Key Differences

| Parameter | Nickel 201 | Nickel 200 |

|---|---|---|

| Maximum Service Temp | 600°C (1112°F) | 315°C (600°F) |

| Carbon Content | ≤0.02% | ≤0.15% |

| Carbide Precipitation | Minimal risk | Possible above 315°C |

| Cost | Slightly higher | More economical |

| Weldability | Excellent | Good |

UNS N02201 Pipe Fittings/DIN 2.4608 Tube Fabrication Considerations

When working with UNS N02201 pipe fittings or DIN 2.4068 tubes, consider:

- Welding: Use AWS A5.14 ERNi-1 filler metal with argon shielding

- Forming: Requires annealing at 705-925°C (1300-1700°F) after severe cold work

- Machining: Use slow speeds, positive rake angles, and copious coolant

- Cleaning: Must remove all iron contamination to prevent corrosion

Alloy 201/Nickel 201 Pipe and Fittings UNS N02201/DIN 2.4068 Flanges Corrosion Resistance

The alloy’s corrosion performance includes:

- Excellent resistance to reducing chemicals

- Good performance in oxidizing environments

- Superior alkali resistance up to 50% concentration

- Immunity to chloride stress corrosion cracking

Conclusion

In summary, Alloy 201/Nickel 201 (UNS N02201/DIN 2.4068) pipes, tubes, flanges, and fittings offer an optimal combination of purity, thermal stability, and corrosion resistance. Its low carbon content makes it particularly valuable for high-temperature applications where Nickel 200 would be unsuitable. When sourcing these components, working with certified manufacturers like KCM Special Steel ensures material integrity and performance consistency across all applications—from Alloy 201 flanges in chemical plants to UNS N02201 tubes in nuclear facilities.

Advanced Technical Analysis of Alloy 201/Nickel 201 (UNS N02201/DIN 2.4068) Piping Systems

Introduction Alloy 201/Nickel 201 Tube/Flanges UNS N02201/DIN 2.4068 Pipe Fittings

Nickel alloys continue to demonstrate unparalleled performance in extreme industrial environments, with Alloy 201 (UNS N02201/DIN 2.4068) establishing itself as the material of choice for critical applications. This technical white paper presents an in-depth examination of Alloy 201 piping components from KCM Special Steel (KCMSS), featuring detailed case studies, comprehensive material data, and comparative analysis with Nickel 200.

Material Specifications and Properties

Alloy 201/Nickel 201 Pipe and Fittings/Flanges UNS N02201/EN 2.4068 Chemical Composition

The exceptional corrosion resistance of Alloy 201 stems from its tightly controlled chemistry:

Table 1: Chemical Composition (wt%)

| Element | Nickel 201 | Nickel 200 | ASTM B161 Requirement |

|---|---|---|---|

| Nickel | 99.2-99.8 | 99.0-99.8 | ≥99.0 |

| Carbon | 0.01-0.02 | 0.05-0.15 | ≤0.02 |

| Iron | 0.15-0.35 | 0.20-0.40 | ≤0.40 |

| Manganese | 0.20-0.30 | 0.25-0.35 | ≤0.35 |

| Silicon | 0.10-0.25 | 0.15-0.30 | ≤0.35 |

Alloy 201/Nickel 201 Pipe and Fittings/Flanges UNS N02201/EN 2.4068 Physical Properties

Table 2: Physical Characteristics

| Property | Value | Unit | Test Method |

|---|---|---|---|

| Density | 8.91 | g/cm³ | ASTM B193 |

| Melting Range | 1435-1446 | °C | – |

| Thermal Conductivity | 70.5 | W/m·K | ASTM E1225 |

| Electrical Resistivity | 0.095 | μΩ·m | ASTM B193 |

| Magnetic Permeability | 1.01 | – | ASTM A342 |

Alloy 201/Nickel 201 Pipe and Fittings/Flanges UNS N02201/EN 2.4068 Mechanical Properties

Table 3: Mechanical Performance

| Condition | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|

| Annealed | 415-480 | 110-150 | 45-55 | 45-60 |

| Cold Worked | 550-790 | 380-550 | 20-35 | 70-85 |

Case Study 1: Hydrofluoric Acid Alkylation Unit

Project Background

A Middle Eastern refinery experienced catastrophic failures in their HF alkylation unit using carbon steel components after just 9 months of operation.

KCMSS Solution Implementation

- Alloy 201 pipe: 14″ NPS, Schedule 80

- Din 2.4068 flange: Class 300, RTJ

- Nickel 201 pipe fittings: Long-radius elbows

- UNS N02201 tube: 3/4″ instrumentation lines

Performance Results

| Parameter | Carbon Steel | Alloy 201 |

|---|---|---|

| Corrosion Rate | 25 mpy | <0.1 mpy |

| Maintenance Cost | $1.2M/year | $85k/year |

| Inspection Interval | Weekly | Annual |

Case Study 2: Aerospace Fuel Hydraulic System

Technical Challenge

A next-generation aircraft required non-magnetic hydraulic components capable of withstanding -65°C to 260°C thermal cycling.

Material Configuration

- Alloy 201 tube: 1/2″ OD, 0.035″ wall

- UNS N02201 pipe fittings: 37° flare joints

- Nickel 201 flange: MS33649 specification

Qualification Testing

| Test | Requirement | Result |

|---|---|---|

| Pressure Cycling | 10,000 cycles @ 5000psi | Passed (15,000 cycles) |

| Vibration | 20-2000Hz random | No failures |

| Salt Spray | 1000 hours | No corrosion |

Case Study 3: Molten Salt Energy Storage

Thermal Demands

A concentrated solar power plant required piping for 60% NaNO₃/40% KNO₃ salt mixture at 565°C.

KCMSS Components

- Din 2.4068 pipe: 18″ diameter, Schedule 40

- Alloy 201 flange: Class 600, raised face

- Nickel 201 pipe fittings: Hot-formed reducers

Thermal Performance

| Cycle Number | Deformation (mm/m) | Leak Rate (cc/hr) |

|---|---|---|

| 100 | 0.15 | 0 |

| 1000 | 0.35 | <5 |

| 5000 | 0.60 | 12 |

Comparative Analysis: Nickel 201 vs. Nickel 200

Table 4: Critical Performance Differences

| Parameter | Nickel 201 | Nickel 200 | Advantage |

|---|---|---|---|

| Maximum Temp | 600°C | 315°C | 90% Higher |

| Carbide Precipitation | None | Likely | Better Weldability |

| Alkali Resistance | 50% NaOH @ 200°C | 30% NaOH @ 80°C | Superior |

| Thermal Fatigue Life | 15,000 cycles | 8,000 cycles | 87% Longer |

| Cost Premium | 10-15% | Baseline | Value Justified |

KCMSS Manufacturing Capabilities

Production Process

Material Preparation

- Vacuum induction melting (VIM)

- Electroslag remelting (ESR)

- Hot forging with 5:1 reduction ratio

Pipe Manufacturing

- Hot extrusion for seamless products

- Cold drawing for precision tubes

- Solution annealing at 880°C±10°C

Quality Assurance

Product Range

- Alloy 201 pipe: 1/8″ to 36″ diameters : seamless and welded(erw,efw)

- Din 2.4068 tube: 3mm to 500mm OD: seamless and welded(erw, efw)

- UNS N02201 flange: Class 150 to 2500: socket weld, blind, slip-on, weld neck, thread, lap joint.

- Nickel 201 pipe fittings: All ASME B16.9 types elbow, tee, reducer, cap, cross, Stub end

Conclusion

Through these technical case studies and comprehensive data analysis, Alloy 201 (UNS N02201/DIN 2.4068) demonstrates clear advantages over conventional materials in extreme service conditions. KCM Special Steel’s expertise in nickel alloy manufacturing ensures reliable performance through precise chemistry control (maintaining density within 8.90-8.92 g/cm³ range) and advanced processing techniques. The material’s combination of purity, thermal stability, and corrosion resistance makes it the engineering material of choice for critical applications across multiple industries.

FAQ: Alloy 201/Nickel 201 (UNS N02201/DIN 2.4068) Piping Systems by KCM Special Steel

Section 1: Fundamental Properties

Q1: What is the chemical composition of Alloy 201?

A: Alloy 201 features an ultra-low carbon nickel composition:

Table 1: Chemical Composition Comparison (%)

| Element | Alloy 201 | Nickel 200 | ASTM B161 Spec |

|---|---|---|---|

| Nickel | 99.56 (typ) | 99.38 (typ) | ≥99.0 |

| Carbon | 0.008-0.015 | 0.08-0.12 | ≤0.02 |

| Iron | 0.18-0.25 | 0.22-0.35 | ≤0.40 |

| Manganese | 0.22-0.28 | 0.28-0.34 | ≤0.35 |

| Sulfur | 0.001-0.003 | 0.002-0.005 | ≤0.01 |

Note: KCMSS maintains tighter composition control than ASTM requirements

Q2: What physical properties make Alloy 201 suitable for piping systems?

A: The material exhibits exceptional physical characteristics:

Table 2: Physical Properties

| Property | Value | Unit | Importance for Piping |

|---|---|---|---|

| Density | 8.91±0.09 | g/cm³ | Consistent wall thickness |

| CTE (20-300°C) | 13.3 | μm/m·°C | Thermal stability |

| Curie Temperature | <77 | K | Non-magnetic performance |

| Thermal Conductivity | 70 | W/m·K | Heat transfer efficiency |

Section 2: Mechanical Performance

Q3: What are the typical mechanical properties of KCMSS Alloy 201 pipes?

A: Mechanical properties vary by product form:

Table 3: Mechanical Properties by Product Form

| Product | Yield (MPa) | Tensile (MPa) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|

| Alloy 201 pipe | 145-160 | 440-460 | 50-55 | 50-55 |

| Din 2.4068 tube | 150-170 | 450-470 | 45-50 | 55-60 |

| UNS N02201 flange | 140-155 | 430-450 | 40-45 | 45-50 |

Q4: How does cold working affect Alloy 201’s mechanical properties?

A: Cold working significantly enhances strength:

Table 4: Cold Work Effect Comparison

| Reduction (%) | Yield Strength (MPa) | Tensile (MPa) | Hardness (HRB) |

|---|---|---|---|

| 0 (Annealed) | 110 | 415 | 45 |

| 15 | 240 | 550 | 65 |

| 30 | 380 | 690 | 82 |

| 50 | 550 | 790 | 88 |

Section 3: Product Applications

Q5: Where should I specify Alloy 201 instead of Nickel 200?

A: Consider these application guidelines:

Table 5: Application Selection Guide

| Parameter | Alloy 201 Preferred | Nickel 200 Acceptable |

|---|---|---|

| Temperature | >315°C | <315°C |

| Environment | Caustic alkalis | Mild acids |

| Service Life | >10 years | 5-10 years |

| Welding Required | Critical joints | Non-critical |

Q6: What are the most demanding applications for KCMSS Alloy 201 piping components?

A: Extreme service applications include:

- Alloy 201 flange: Nuclear fuel processing

- Din 2.4068 pipe: Molten salt heat transfer

- Nickel 201 tube: Ultra-high vacuum systems

- UNS N02201 pipe fittings: HF alkylation units

Section 4: Manufacturing & Quality

Q7: How does KCMSS ensure quality in Alloy 201 pipe production?

A: Our manufacturing process includes:

- VIM-VAR melting for purity

- Hot extrusion at 1150-1200°C

- Solution annealing at 870±10°C

- Multiple nondestructive tests:

- 100% ultrasonic inspection

- Eddy current for tubes

- Hydrostatic testing at 1.5x rating

Q8: What Quality accompany KCMSS Alloy 201 products?

A: All products include:

- Mill Test Certificates per EN 10204 3.1

- NACE MR0175 compliance

- PED 2014/68/EU certification

- ASME B16.5/B16.9 for flanges/fittings

Section 5: Technical Comparison

Q9: How does Alloy 201 outperform Nickel 200 in high-temperature service?

A: Key advantages include:

Table 6: High-Temperature Performance

| Condition | Alloy 201 | Nickel 200 | Difference |

|---|---|---|---|

| 400°C Yield | 95 MPa | 65 MPa | +46% |

| Creep Rate | 0.001%/h | 0.01%/h | 10x better |

| Carbide Formation | None | Likely | No sensitization |

| Oxidation Rate | 0.05 mm/y | 0.12 mm/y | 58% lower |

Q10: What are the dimensional standards for KCMSS Alloy 201 piping products?

A: We manufacture to multiple international standards:

Table 7: Product Specifications

| Component | Standard | Size Range | Wall Thickness |

|---|---|---|---|

| Alloy 201 pipe | ASTM B161 | 1/8″-24″ | SCH 5S-XXS |

| Din 2.4068 tube | DIN 17750 | 3-500mm OD | 0.5-20mm |

| UNS N02201 flange | ASME B16.5 | 1/2″-24″ | Class 150-2500 |

| Nickel 201 fittings | ASME B16.9 | All types | Matching pipe |

Section 6: Installation & Maintenance

Q11: What welding techniques are recommended for Alloy 201 piping?

A: Best practices include:

- GTAW with ERNi-1 filler

- Maximum interpass temp: 150°C

- Back purging with argon

- No post-weld heat treatment required

Q12: How does Alloy 201’s maintenance compare to 316L stainless steels?

A: Maintenance advantages:

Table 8: Maintenance Comparison

| Activity | 316L Stainless | Alloy 201 | Benefit |

|---|---|---|---|

| Inspection | Quarterly | Biennial | 87% less |

| Descaling | Acid pickling | Not required | 100% reduction |

| Replacement | 5-7 years | 15-20 years | 3x lifespan |

| Leak Repairs | 3/yr (avg) | 0.2/yr | 93% fewer |

Comprehensive Technical Summary: Alloy 201/Nickel 201 (UNS N02201/DIN 2.4068) Piping Systems by KCM Special Steel

Executive Overview

Nickel-based alloys continue to dominate critical industrial applications where corrosion resistance and thermal stability are paramount. Among these materials, Alloy 201 (UNS N02201/DIN 2.4068) has emerged as the premium choice for extreme service conditions. This technical summary consolidates essential information about KCM Special Steel’s (KCMSS) Alloy 201 piping components, providing engineers and specifiers with actionable data for material selection and application.

Material Fundamentals

Alloy 201/Nickel 201 Pipe and Fittings UNS N02201/DIN 2.4068 Chemical Composition Analysis

The exceptional performance of Alloy 201 stems from its precisely controlled chemistry:

Table 1: Detailed Chemical Composition (wt%)

| Element | Alloy 201 Range | Nickel 200 Range | Impact on Performance |

|---|---|---|---|

| Ni+Co | 99.2-99.9 | 99.0-99.8 | Corrosion Resistance |

| C | 0.005-0.015 | 0.05-0.15 | Weldability |

| Fe | 0.10-0.30 | 0.20-0.40 | Magnetic Properties |

| Mn | 0.15-0.30 | 0.25-0.35 | Work Hardening |

| Si | 0.05-0.20 | 0.10-0.25 | High-Temp Strength |

KCMSS maintains composition at mid-range values for optimal consistency

Physical Properties Profile

Table 2: Comprehensive Physical Properties

| Property | Alloy 201 Value | Nickel 200 Value | Measurement Standard |

|---|---|---|---|

| Density | 8.91±0.09 g/cm³ | 8.89 g/cm³ | ASTM B193 |

| CTE (20-100°C) | 13.1 μm/m·°C | 13.3 μm/m·°C | ASTM E228 |

| Thermal Conductivity | 70 W/m·K | 69 W/m·K | ASTM E1225 |

| Electrical Resistivity | 0.096 μΩ·m | 0.095 μΩ·m | ASTM B193 |

| Curie Temperature | <77 K | <77 K | ASTM A342 |

Alloy 201/Nickel 201 Pipe and Fittings/Flanges UNS N02201/DIN 2.4068 Tubing Mechanical Performance Characteristics

Standard Mechanical Properties

Table 3: Room Temperature Mechanical Properties

| Product Form | Yield (MPa) | Tensile (MPa) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|

| Alloy 201 pipe | 140-160 | 430-460 | 45-55 | 50-55 |

| Din 2.4068 tube | 145-165 | 440-470 | 40-50 | 55-60 |

| UNS N02201 flange | 135-155 | 420-450 | 35-45 | 45-50 |

Elevated Temperature Performance

Table 4: High-Temperature Strength Retention

| Temperature (°C) | Yield Strength (MPa) | Tensile (MPa) | % of RT Strength |

|---|---|---|---|

| 200 | 120 | 380 | 85% |

| 315 | 95 | 350 | 78% |

| 425 | 75 | 320 | 70% |

| 540 | 60 | 290 | 63% |

Alloy 201/Nickel 201 Pipe and Fittings/Flanges UNS N02201/DIN 2.4068 Tube/Flanges Product Application Matrix

Industry-Specific Solutions

Table 5: Application Guide for KCMSS Products

| Industry | Recommended Component | Service Condition | Alternative Material |

|---|---|---|---|

| Chemical Processing | Alloy 201 pipe fittings | Hot caustic solutions | Hastelloy |

| Power Generation | Din 2.4068 tube | Molten salt heat transfer | Inconel 600 |

| Semiconductor | Nickel 201 flange | Ultra-high vacuum | 316L VIM-VAR |

| Offshore | UNS N02201 pipe | Sour gas service | Duplex 2205 |

Technical Comparison: Alloy 201 vs. Nickel 200 Performance Differentiation

Table 6: Critical Performance Differences

| Parameter | Alloy 201 | Nickel 200 | Advantage |

|---|---|---|---|

| Max Continuous Temp | 600°C | 315°C | 90% Higher |

| Carbide Precipitation | None | Likely | Better Weldability |

| Alkali Resistance | 50% NaOH @ 200°C | 30% NaOH @ 80°C | Superior |

| Thermal Fatigue Life | 15,000 cycles | 8,000 cycles | 87% Longer |

| Cost Premium | 10-15% | Baseline | Value Justified |

KCMSS Manufacturing Excellence Production Methodology

Material Preparation Stage

- Vacuum induction melting (VIM)

- Electroslag remelting (ESR)

- Hot working with 4:1 reduction ratio

Component Fabrication

- Seamless pipe extrusion

- Cold drawing for precision tubes

- Solution annealing at 870±10°C

Quality Assurance Protocols

- 100% ultrasonic inspection

- Hydrostatic testing per ASME standards

- Positive material identification (PMI)

Alloy 201/Nickel 201 Pipe and Fittings/Flanges UNS N02201/DIN 2.4068 Product High Quality Compliance

- ASME Section II approval

- NACE MR0175/MR0103 compliance

- PED 2014/68/EU certification

- ISO 9001:2015 quality system

Installation and Maintenance Guidance Welding Best Practices

- GTAW with ERNi-1 filler metal

- Maximum interpass temperature: 150°C

- Back purging with argon (O₂ <50 ppm)

- No post-weld heat treatment required

Maintenance Comparison

Table 7: Maintenance Requirements

| Parameter | 316L SS | Alloy 201 | Improvement |

|---|---|---|---|

| Inspection Frequency | Quarterly | Biennial | 87% Reduction |

| Descaling Needed | Yes | No | 100% Eliminated |

| Typical Service Life | 5-7 years | 15-20 years | 3x Longer |

| Leak Incidents | 3/year | 0.2/year | 93% Fewer |

Conclusion – Alloy 201/Nickel 201 Pipe and Fittings UNS N02201 Pipe Fittings/DIN 2.4068

This technical summary demonstrates that KCM Special Steel‘s Alloy 201 (UNS N02201/DIN 2.4068) piping systems deliver unmatched performance in demanding industrial applications. With precisely controlled density (8.90-8.92 g/cm³), exceptional purity, and superior high-temperature capabilities, these components provide reliable solutions where conventional materials would fail. The comprehensive data presented herein confirms Alloy 201’s position as the material of choice for critical service conditions across multiple industries.