What are the Stainless Steel Flanges?

Based on key technical standards (ASME B16.5, B16.47, EN 1092-1, ISO 7005-1):

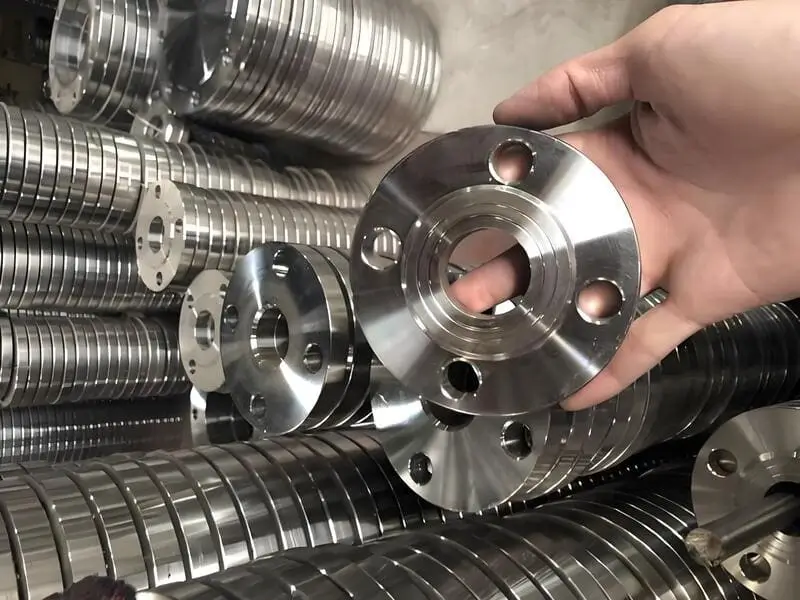

Stainless steel flanges are standardized ring-shaped fittings, fabricated from corrosion-resistant chromium-alloyed steel (min. 10.5% Cr), designed to connect, disconnect, and seal piping system components (pipes, valves, equipment). They provide leak-proof joints via bolting to mating flanges using gaskets/seals, enabling assembly, maintenance, and ensuring pressure containment, alignment, and structural integrity.

Stainless steel flanges serve as the critical connective joints in diverse piping networks, ensuring leak-proof, robust, and maintainable systems across demanding industrial environments. Their standardized design and material versatility facilitate global compatibility and operational safety.

I. Core Standards of Stainless Steel Flanges/Duplex Steel Flanges

Global standardization ensures interoperability and safety. Key standards include:

1. Chinese National Standards (GB) Stainless Steel Flange:

* Scope: Covers dimensions, materials, and technical requirements for flanges from DN10 to DN5000.

* Key Series: GB/T 9112-9124 (Pipe Flanges & Flange Fittings), GB/T 9113-2000 ~ GB/T 9124-2000 (Specific flange types)27.

* Pressure Vessels: JB 1157-82 ~ JB 1160-82, JB 4700-2000 ~ JB 4707-2000.

2. American Standards (ANSI/ASME) Duplex/Stainless Steel Flanges:

* ANSI B16.5: The primary standard for pipe flanges (NPS 1/2″ to NPS 24″) and flanged fittings.

* Pressure Classes: 150, 300, 600, 900, 1500, 2500 Lbs.

* Common Types: Weld Neck (WN), Slip-On (SO), Blind (BL), Threaded (TH), Lap Joint (LJ), Socket Weld (SW).

3. Japanese Standards (JIS)Duplex/Stainless Steel Flanges:

* JIS B 2220 (formerly JIS F 7806 / JIS 2210-1994): Specifies steel pipe flanges.

* Pressure Ratings: 5K, 10K, 16K, 20K.

* Common Types: Plate (PL), Slip-On (SO), Blind (BL), Weld Neck (WN), Threaded (TH), Socket Weld (SW).

4. German / European Standards (DIN/EN):

* Core DIN Standards: 2573 (PN6 Plate), 2572 (PN10 Plate), 2631 (PN6 WN/SO), 2632 (PN10 WN/SO), 2633 (PN16 WN/SO), 2634 (PN25 WN/SO), 2543 (PN40), 2545 (PN100), 2576 (PN16 BL), DIN EN 1092-1 supersedes many.

* Common Types: Plate (PL), Slip-On (SO), Weld Neck (WN), Blind (BL), Threaded (TH).

5. Chinese Ministry Standards (HG/JB/SH):

* Chemical Industry (HG): Extensive coverage including HG 20592-2009 (PN Series), HG 20615-2009 (Class Series), HG 5010-52 ~ HG 5028-58, HGJ 44-91 ~ HGJ 65-91.

* Machinery Industry (JB): JB 81-59 ~ JB 86-59, JB/T 74-94 ~ JB/T 86-94.

* Petrochemical Industry (SH): SH 3406-2000 series.

Table 1: Major International Flange Standards & Pressure Ratings

| Standard System | Key Standard Codes | Pressure Class/Range | Common Flange Types |

|---|---|---|---|

| GB (China) | GB/T 9112-9124, GB/T 9113-2000+ | PN0.25 – PN42.0 MPa | PL, SO, WN, BL, TH, LJ, SW |

| ANSI/ASME (USA) | ANSI B16.5 | 150, 300, 600, 900, 1500, 2500 Lbs | WN, SO, BL, TH, LJ, SW |

| JIS (Japan) | JIS B 2220 / JIS 2210 | 5K, 10K, 16K, 20K | PL, SO, BL, WN, TH, SW |

| DIN/EN (Germany/EU) | DIN 2572-2634, EN 1092-1 | PN6, PN10, PN16, PN25, PN40, PN100 | PL, SO, WN, BL, TH |

| HG (China Chem) | HG 20592-2009 (PN), HG 20615 (Class) | PN Series (e.g., PN10, PN16, PN25… PN160), Class Analogous | Comprehensive range matching GB/ANSI types |

II. Material Composition & Performance Characteristics

Stainless steel flanges leverage alloys renowned for corrosion resistance and strength:

Austenitic Grades (Dominant):

- 304 (0Cr18Ni9 / SUS304): Excellent general corrosion resistance, formability, weldability. Widely used in food, water, mild chemical services.

- 304L: Low-carbon variant of 304, superior resistance to sensitization (intergranular corrosion) post-welding.

- 321 (1Cr18Ni10Ti / SUS321): Stabilized with titanium, offering enhanced intergranular corrosion resistance after exposure to high temperatures (e.g., exhaust systems).

- 316 (0Cr17Ni12Mo2 / SUS316): Molybdenum addition significantly improves resistance to pitting and crevice corrosion, especially by chlorides. Common in marine, chemical, and pharmaceutical applications.

- 316L: Low-carbon variant of 316 for welded applications to prevent sensitization.

- 310S (0Cr25Ni20 / SUS310S): High chromium and nickel content provides outstanding oxidation resistance at high temperatures. Used in furnaces, heat exchangers8.

Duplex Stainless Steel Flanges: A Robust Alternative

Duplex steel flanges combine ferritic and austenitic microstructures, offering a distinct advantage by balancing properties:- Strength: Approximately double the yield strength of standard austenitic grades (304/316), enabling thinner, lighter designs under high pressures.

- Corrosion Resistance: Excellent resistance to stress corrosion cracking (SCC), pitting, and crevice corrosion, often exceeding 316L, particularly in chloride-rich environments. Pitting Resistance Equivalent Number (PREN) > 34.

- Cost-Effectiveness: Higher alloy content than 304/316, but strength advantages can reduce material volume requirements. Generally more cost-effective than high-nickel alloys.

- Density: Duplex stainless steel flanges exhibit a density typically within the range of approximately 1% to 2% lower than standard austenitic grades like 304 or 316. This translates to densities around 7.7 – 7.8 g/cm³ compared to 7.9 – 8.0 g/cm³ for austenitics.

Table 2: Key Properties of Common Austenitic vs. Duplex Stainless Steels for Flanges

| Property | Austenitic (e.g., 316L) | Duplex (e.g., 2205 / S31803/S32205) | Advantage |

|---|---|---|---|

| Microstructure | Fully Austenitic | ~50% Ferrite / ~50% Austenite | Duplex: Balanced Strength/Corrosion |

| Yield Strength (Min MPa) | ~170 (316L) | ~450 (2205) | Duplex: ~2.5x Higher Yield |

| Corrosion Resistance | Good (316L: Moderate Chlorides) | Very Good (Excellent SCC/Pitting Resistance) | Duplex: Superior in Chlorides |

| Stress Corrosion Cracking (SCC) | Susceptible in Cl⁻ above ~60°C | Highly Resistant | Duplex: Major Advantage |

| Toughness (Impact) | Excellent at Cryogenic Temperatures | Good down to ~-50°C | Austenitic: Better Cryogenic |

| Thermal Expansion | Higher | Lower (~1.5×10⁻⁶/K vs ~1.7×10⁻⁶/K) | Duplex: Better Thermal Stability |

| Thermal Conductivity | Lower (~15 W/m·K) | Higher (~19 W/m·K) | Duplex: Better Heat Transfer |

| Density (g/cm³) | ~7.9 – 8.0 | ~7.7 – 7.8 | Duplex: ~1-2% Lighter |

| Typical Applications | General Chemical, Food, Pharma, Water | Offshore Oil & Gas, Chemical Processing, Desalination, Pulp & Paper | Duplex: Harsh Environments |

III. Comprehensive Flange Types & Pressure Ratings

The diverse flange types accommodate specific pressure, installation, and maintenance needs:

Common Flange Types:

- Plate/Flat (PL): Simple face, cost-effective. Primarily for low pressures (PN ≤ 10) using gaskets covering bolt holes. Often requires double welding.

- Stainless Steel Slip-On (SO) Flange: Slides over pipe end, fillet welded inside and outside. Easier alignment than weld neck, suitable for moderate pressures.

- Stainless Steel Weld Neck (WN) Flange: Features a tapered hub butt-welded to pipe. Provides superior strength, stress distribution, and fatigue resistance for high pressures/temperatures/vibration. Preferred for critical applications.

- Stainless Steel Blind (BL) Flange: Closes off pipe ends, valves, or vessel openings. Used for pressure testing, isolation, or future expansion.

- Threaded (TH): Screws onto externally threaded pipe. Used for low-pressure, non-critical services where welding is undesirable.

- Stainless Steel Socket Weld (SW) Flange: Pipe inserted into socket, fillet welded. Offers good strength for small bore high-pressure lines.

- Lap Joint (LJ): Used with a stub end. Allows easy alignment and disassembly (e.g., for frequent cleaning). The flange itself bears no pressure load.

- Reducing: Connects pipes of different diameters.

Specialized Flange Types:

- Screwed/Threaded Flange: Similar to threaded but incorporates a seal weld beyond threads for enhanced leak-tightness.

- Orifice: Features tapped holes for orifice plate installation for flow measurement.

- Expander/Reducer: Facilitates pipeline size changes. Expander increases, reducer decreases diameter.

- Swivel Ring: Central flange ring rotates independently, simplifying bolt hole alignment during installation (common offshore).

- Anchor Flange: Designed to restrain axial pipe movement and absorb thrust forces, typically embedded in concrete.

- Vanstone/Lined Flange: Features a loose liner (e.g., PTFE) for exceptional chemical resistance where the base flange provides structural support.

Pressure Rating Spectrum:

Stainless steel flanges accommodate pressures from near atmospheric to extremely high:- Metric (PN): PN0.25, PN0.6, PN1.0, PN1.6, PN2.5, PN4.0, PN6.3, PN10.0, PN16.0, PN25.0, PN40.0, PN63.0, PN100.0, PN160.0, PN250.0, PN320.0, PN400.0, PN420.0 MPa.

- ASME Class (Lbs): 150, 300, 400, 600, 900, 1500, 2500.

- JIS Rating (K): 5K, 10K, 16K, 20K.

Selection depends on design pressure, temperature, fluid, and applicable standard.

VI. Fabrication & Quality Considerations

While standards define dimensions, fabrication quality is paramount:

- Welding: Proper procedures (WPS/PQR) and qualified welders are crucial, especially for WN and SW flanges. Post-weld heat treatment may be needed for thick sections or specific grades. Avoiding weld defects like porosity or undercut is essential.

- Machining: Precise facing, drilling, and boring are vital for flange flatness, sealing surface finish (e.g., Ra value for RF), and bolt hole alignment.

- Dimensional Inspection: Verifying OD, thickness, bore, PCD, bolt hole size/spacing against the standard.

- Material Certification: Mill Test Certificates (MTCs) confirming chemical composition and mechanical properties per specification (e.g., ASTM A182).

- Non-Destructive Testing (NDT): Often required for critical service (e.g., RT, UT, PT, MT per applicable code).

- Surface Finish: Particularly important for RF faces and hygienic applications. Avoiding grinding marks and ensuring uniformity is key to sealing.

Conclusion: The Foundation of Secure Connections

Stainless steel flanges, governed by intricate international standards like ANSI B16.5, DIN EN 1092-1, GB/T, HG, and JIS B 2220, provide the essential backbone for constructing safe, reliable, and maintainable piping infrastructure.

Understanding the nuances of flange types (from WN and SO to specialized Anchor or Swivel Ring flanges), pressure ratings (PN, Class, K), and the exceptional properties offered by different grades – particularly the strength and corrosion resistance of duplex stainless steel flanges with their advantageous density profile – is fundamental for optimal system design.

Their pervasive use across industries ranging from offshore oil platforms demanding duplex steel solutions to ultra-clean pharmaceutical facilities underscores their critical role in modern engineering. Adherence to standards and meticulous attention to quality in manufacturing ensures these components perform reliably under the most challenging conditions for decades.