Introduction: Addressing Global Water Scarcity

Development and Application of 904L Stainless Steel for Seawater Desalination Plants,The escalating global water crisis has intensified the demand for reliable seawater desalination solutions. As populations grow and freshwater sources dwindle, large-scale desalination plants represent a critical strategy for augmenting water supplies.

Significantly, controlling construction costs while enhancing production capacity is paramount for the economic viability of these facilities. Large evaporative desalination units, prized for their high water output capabilities, necessitate the deployment of advanced corrosion-resistant materials due to the inherently aggressive marine environment.

Among these materials, duplex stainless steels (DSS) have emerged as a primary choice. To broaden user options and facilitate the selection of more cost-effective and technically suitable materials, Nippon Steel & Sumikin Stainless Steel Corporation (NSSC) pioneered the development of a weldable, low-alloy duplex stainless steel: 904L. This article comprehensively details the defining characteristics and diverse applications of this newly engineered 904L stainless steel, particularly within seawater desalination infrastructure and beyond.

1. Stainless Steel Selection for Modern Desalination Plants - Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Multi-stage flash (MSF) desalination technology stands out for its efficiency in producing substantial volumes of fresh water from seawater. Consequently, the metallic materials employed within these plants must withstand an exceptionally challenging environment characterized by high chloride concentrations, elevated temperatures, and varying salinity levels. Engineers strategically combine different grades of stainless steel based on the specific salt concentration and temperature profiles encountered at various stages of the desalination process.

- Austenitic Stainless Steels: In zones experiencing lower salinity and moderately corrosive conditions, austenitic grades like 316L are commonly utilized. This grade offers excellent pitting corrosion resistance, a crucial property for longevity in chloride-rich environments.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

- Duplex Stainless Steels (DSS): Areas subjected to higher salt concentrations and more severe corrosive regimes, such as high-temperature brine heaters and heat recovery sections, demand superior materials. DSS grades excel here due to their inherent metallurgical advantage: significantly enhanced resistance to chloride-induced stress corrosion cracking (SCC) compared to their austenitic counterparts. This resistance stems from the characteristic biphasic microstructure comprising roughly equal proportions of austenite and ferrite phases. Importantly, however, the overall corrosion resistance of duplex steels is highly dependent on the content of key alloying elements like Nickel (Ni) and Molybdenum (Mo).

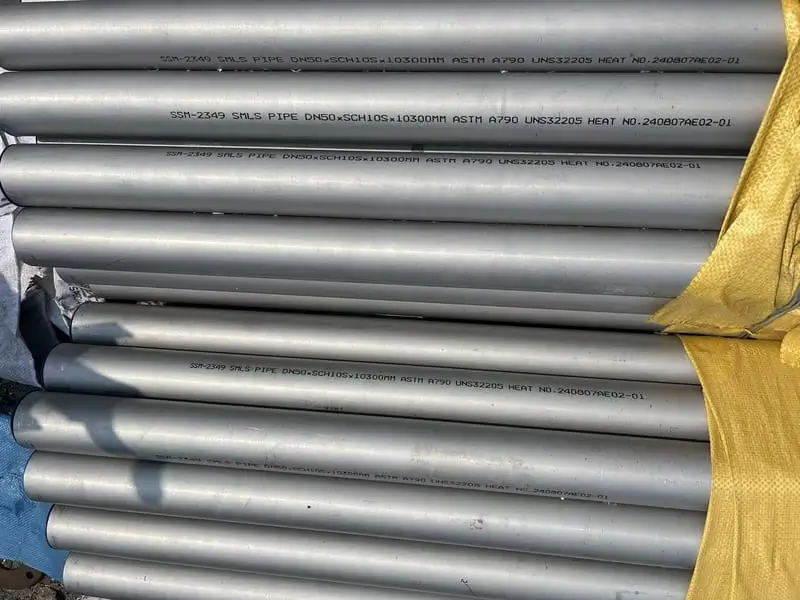

The ASTM S31803 grade (UNS S32205), commonly known as 2205 DSS (22% Cr, 5% Ni, 3% Mo), represents the benchmark standard for duplex stainless steels in such demanding applications. To optimize cost-effectiveness, a category known as low-alloy duplex stainless steels has been developed. These grades, such as S32101 (21% Cr, 1.5% Ni, N), maintain the duplex structure and core benefits while minimizing the use of expensive alloying elements like Ni and Mo.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Table 1: Stainless Steel Application Guide for MSF Desalination Plants

| Process Zone | Corrosion Environment | Typical Material Choices | Material Type |

|---|---|---|---|

| Cooler Sections / Lower Temp | Moderate Salinity, Lower Temperature, Lower Corrosion | 316L | Austenitic Stainless |

| Moderate Temp Sections | Increasing Salinity & Temperature | 316L, Lean Duplex (e.g., S32101, 904L) | Austenitic / Duplex DSS |

| Hot Brine Sections / Heaters | High Salinity, High Temperature, Severe Corrosion | S31803 (2205), Higher Alloy DSS/SAS | Duplex / Super Austenitic |

| Critical Components | Very High Stress/Corrosion Risk | Super Duplex (e.g., S32750) / Nickel Alloys | Duplex / Nickel Alloys |

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

2. Development and Key Characteristics of 904L Stainless Steel - Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

The advent of low-alloy duplex stainless steels, specifically designed to minimize the addition of costly precious metals like Ni and Mo, has markedly expanded the application potential of duplex grades. These steels offer a compelling combination of advantages:

- Equivalent Corrosion Resistance: In moderately saline environments, their corrosion resistance matches that of conventional austenitic stainless steels like 304L/316L.

- Reduced Cost and Stability: Lower reliance on expensive alloying elements translates to decreased material costs and reduced susceptibility to price volatility associated with Ni and Mo markets.

- Enhanced Mechanical Strength: Yield strength is approximately double that of comparable austenitic grades, allowing for material savings through thinner sections and providing superior resistance to deformation/stress.

Therefore, low-alloy duplex steels present an economical alternative to conventional austenitic stainless steels, enabling broader adoption. Despite these advantages, earlier low-alloy duplex steels, exemplified by S32101, faced significant limitations concerning weldability. Particularly problematic was the degradation of corrosion resistance and toughness in the heat-affected zone (HAZ) when subjected to high-heat-input welding processes. This drawback rendered efficient welding techniques like Submerged Arc Welding (SAW) unsuitable for critical structural fabrications, hindering their widespread use.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

NSSC addressed these challenges head-on with the development of 904L. Its core chemical composition is centered around 21% Chromium (Cr), 2% Nickel (Ni), with controlled Nitrogen (N) additions. Crucially, through meticulous optimization of the elemental balance – carefully adjusting Cr, Ni, N, and minor alloying elements – the developers successfully resolved the welding issues plaguing previous low-alloy duplex grades. 904L demonstrates excellent tolerance to high-heat-input welding, making SAW and other efficient processes viable for large-scale structural applications without compromising critical properties.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Performance Validation: Corrosion Resistance

Rigorous testing validates the performance of 904L. Comparative evaluations in artificial seawater using Critical Pitting Temperature (CPT) or Critical Crevice Corrosion Temperature (CCT) tests reveal that 904L plate exhibits pitting corrosion resistance equivalent to TY304 (a standard 304L austenitic stainless steel grade). This level of pitting resistance is suitable for many moderately corrosive zones within desalination plants and comparable environments.

More significantly, 904L demonstrates superior resistance to Stress Corrosion Cracking (SCC) compared to TY304. This heightened resilience arises directly from the inherent characteristics of the duplex microstructure combined with its higher strength. The ferrite phase inherently resists SCC initiation, while the austenite phase provides toughness. The inherent strength of the duplex structure also helps resist the tensile stresses that contribute to SCC propagation.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Table 2: Comparative Properties of Key Stainless Steels for Desalination

| Material Grade | Type | Nominal Composition | Key Strengths | Key Limitations / Challenges | Pitting Resistance (vs Ref) | SCC Resistance (vs Ref) | Weldability (High HI) |

|---|---|---|---|---|---|---|---|

| TY304 / 304L | Austenitic | 18Cr-8Ni | Good formability, weldability, low cost | Moderate pitting/SCC resistance | Baseline | Lower | Good |

| 316L | Austenitic | 16Cr-10Ni-2Mo | Good pitting resistance, widely available | Susceptible to SCC in hot chloride envs. | Better than 304L | Lower | Good |

| S32101 (2101) | Low-Alloy Duplex | 21Cr-1.5Ni-0.3Mo-5Mn-0.2N | High strength, cost-effective, good mod. corrosion resist. | Poor HAZ corrosion/toughness after high-HI welding | Good (~316L) | Good | Poor |

| S31803 (2205) | Standard Duplex | 22Cr-5Ni-3Mo-0.15N | Excellent SCC resistance, high strength, good pitting resist. | Higher cost than austenitics/lean duplex | Very Good | Very Good | Good (Standard) |

| 904L (NSSC) | Low-Alloy Duplex | 21Cr-2Ni-N (Optimized) | High strength, cost-effective, Good SCC resist., Excellent High-HI Weldability | Pitting resist. moderate (less than 2205) | Good (~TY304) | Better than TY304 | Good |

| Super Austenitics | Austenitic | e.g., 904L (20Cr-25Ni-4.5Mo) | Exceptional pitting/SCC resistance | Very High Cost, Lower Strength than Duplex |

3. Application in Seawater Desalination Plants: A Case Study - Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

The compelling properties of 904L stainless steel tube prompted rigorous evaluation for its suitability in seawater desalination infrastructure. The outcome was its successful integration into Qatar’s largest seawater desalination facility. This landmark project exemplifies the practical advantages of 904L.

- Significant Volume Utilization: The plant incorporated a substantial 3,200 tons of duplex stainless steel in total.

- 904L’s Contribution: Within this DSS usage, a noteworthy 700 tons comprised 904L stainless steel.

- Primary Driver for Adoption: The dramatic improvement in weldability and weld operability was the key factor, enabling efficient fabrication where traditional low-alloy duplex like S32101 proved problematic. This superior weldability facilitated faster, more reliable construction processes.

- Replacement Role: Functionally, 904L effectively replaced S32101 in designated sections, offering comparable corrosion performance at similar cost but without the welding constraints.

- Future Outlook: Given its performance in Qatar and the ongoing demand for large-scale desalination in arid regions, 904L stainless steel tube is poised for expanded deployment throughout the Middle East and other regions investing heavily in desalination capacity.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Table 3: 904L Deployment in Qatar’s Landmark Desalination Plant

| Project Aspect | Details | Significance for 904L |

|---|---|---|

| Project Location | Qatar | Region with high reliance on large-scale desalination |

| Plant Type & Capacity | Large-Scale MSF Desalination (Specific capacity not stated) | Demanding environment requiring robust materials |

| Total DSS Usage | 3,200 tons | Highlights significant reliance on duplex technology |

| 904L Stainless Steel Usage | 700 tons | Substantial initial adoption volume |

| Primary Application Form | Tubes (Implied for heat exchanger or structural components) | Critical components where weldability and corrosion resistance are paramount |

| Key Reason for Selection | Superior Weldability & Fabrication Operability | Solved the high-heat-input welding limitations of S32101 |

| Material Replaced | S32101 | Demonstrated direct economic/technical replacement potential |

| Future Application Scope | Expansion across Middle East large-scale desalination projects | Validates performance and establishes market potential |

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

4. Expanding Horizons: Applications in Diverse Industries - Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

The success of 904L stainless steel for Seawater Desalination Plants has spurred its adoption across a spectrum of other demanding industries, leveraging its optimal balance of properties:

- Shipbuilding (Oil Tankers): Japan’s shipbuilding sector has extensively adopted 904L stainless steel plate for constructing coastal oil tankers. It effectively replaces TY304 (304L) austenitic stainless steel and coated carbon steel plates in specific structural and cladding applications. This substitution delivers crucial corrosion resistance vital for the marine environment, coupled with excellent formability and weldability for efficient manufacturing. Furthermore, it significantly simplifies maintenance routines during the vessel’s operational life, reducing downtime and lifecycle costs. Based on this success, the application is expected to expand to long-range ocean-going tankers, where durability and reduced maintenance offer even greater economic benefits over long voyages.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

- Water Infrastructure: 904L presents a robust solution for reservoir gates, sluices, and various water treatment equipment components. These applications demand materials resistant to both corrosion (from water, treatment chemicals, and atmospheric exposure) and mechanical wear. The impetus for adoption in Japan is particularly strong following the catastrophic damage inflicted on coastal infrastructure in the Tohoku region by the Great East Japan Earthquake and Tsunami. The extensive, ongoing medium-to-long-term maintenance and reconstruction efforts for gates, sluices, and water treatment facilities throughout the affected areas represent a significant potential market for durable materials like 904L.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

- Construction and Architecture: The construction industry is increasingly recognizing the benefits of 904L stainless steel plate. Its high strength-to-weight ratio enables lightweight designs, while its inherent corrosion resistance eliminates the need for protective coatings and minimizes maintenance requirements (“maintenance-free”). Consequently, it offers a compelling alternative to galvanized steel sheets for structural components, cladding, brackets, and architectural fittings. Its stress-strain behavior (elastic-plastic properties under tensile load) exhibits characteristics closer to carbon steel than conventional austenitic stainless steels, making it more suitable for broader structural applications where predictable mechanical response is critical.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

- Renewable Energy (Solar): A rapidly growing application is in large-scale solar panel mounting structures (solar farms). 904L is increasingly replacing galvanized steel in these systems. The primary drivers for this shift are the elimination of maintenance (avoiding costly re-coating of galvanized steel exposed to harsh weather) and the benefits of lightweight design (simplifying installation and reducing structural load requirements), ultimately contributing to lower overall lifecycle costs. This combination of advantages presents the strongest rationale for its adoption in solar infrastructure.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

Table 4: Diverse Industrial Applications of 904L Stainless Steel

| Industry Sector | Key Applications | Replacing Materials | Primary Benefits of 904L | Future Growth Potential |

|---|---|---|---|---|

| Shipbuilding | Coastal Tanker Structures/Cladding | TY304, Coated Carbon Steel | Corrosion Resistance, Weldability, Simplified Maintenance | Ocean-Going Tankers |

| Water Management | Reservoir Gates, Sluices, Treatment Equip. | Carbon Steel, Coated Steels | Corrosion Resistance, Durability, Low Maintenance | Post-Disaster Rebuild (Japan), Global WTP |

| Construction | Structural Components, Cladding, Fittings | Galvanized Steel Sheets | Lightweight Design, Maintenance-Free, Structural Suitability | Architecture, Infrastructure |

| Renewable Energy | Large Solar Panel Mounting Structures | Galvanized Steel | Maintenance-Free, Lightweight, Lower Lifecycle Cost | High Growth (Solar Farm Expansion) |

| General Industry | Chemical Processing, Pulp & Paper (Mod.) | 304L, 316L, Carbon Steel | Cost-Effective Corrosion Resistance, Strength, Weldability | Moderate Corrosion Environments |

5. Conclusion and Future Outlook - 904L Stainless Steel for Seawater Desalination Plants

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

904L stainless steel plate has established itself as a versatile and economically advantageous material, primarily due to its dual strengths: corrosion resistance equivalent to TY304 (304L) in moderately aggressive environments and significantly higher mechanical strength. This robust combination suggests a future where its application extends far beyond its initial target in energy-related equipment like desalination plants. Its potential for widespread adoption across numerous industries is substantial.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

The trajectory for 904L is demonstrably upward. Its product range is continuously diversifying, evolving from initial offerings focused on thick plates to now include sheets, bars, and wire rods. This expansion caters to a broader spectrum of manufacturing needs and component types. Furthermore, collaboration across the supply chain has been instrumental. Through partnerships with downstream processors, a comprehensive portfolio of secondary processed products has been developed. This portfolio includes essential components like welded tubes and pipes, fittings (joints), structural shapes (sections), and castings/forgings. This extensive range ensures that diverse customer requirements can be efficiently met, simplifying the sourcing and integration of 904L components into complex systems.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants

In essence, 904L stainless steel represents a significant advancement in materials technology. By successfully overcoming the weldability limitations of earlier low-alloy duplex grades while retaining their core economic and mechanical benefits, NSSC has provided engineers and designers with a powerful tool. Its proven performance in critical seawater desalination applications, coupled with its expanding footprint in shipbuilding, water infrastructure, construction, and renewable energy, underscores its potential to become a mainstay material for demanding, cost-sensitive applications where longevity and reliability are paramount. Its journey from a solution for desalination welding challenges to a multi-industry material highlights its inherent value and adaptability.

Development and Application of 904L Stainless Steel for Seawater Desalination Plants