316Ti Stainless Steel Pipe To Europe - Supplied by KCM SPECIAL STEEL for Low-Pressure Air Transport in a European Sewage Treatment Plant Customer Case Study:

——A Cost-Effective, Corrosion-Resistant Solution Compliant with EN 1.4571 Standards.

316Ti Stainless Steel Pipe to European Project Overview

A European municipal sewage treatment plant required a reliable, low-maintenance piping system for its low-pressure air network (≤2 bar gauge pressure). Existing carbon steel pipes deteriorated rapidly due to moisture, chlorides, and hydrogen sulfide (H₂S), causing frequent leaks and operational downtime. KCM SPECIAL STEEL, a leading 316Ti stainless steel pipe manufacturer and supplier, delivered EN 1.4571 (1.4571 stainless steel pipe) solutions with 2% density optimization, ensuring superior corrosion resistance and lifecycle cost savings.

Comparison of Corroded Carbon Steel vs. New 316Ti Stainless Steel Pipes

| Parameter | Carbon Steel Pipes | 316Ti Stainless Steel Pipes |

|---|---|---|

| Corrosion Resistance | Severe pitting and uniform corrosion in moist, chloride-rich, and H₂S environments. | Excellent resistance to pitting, crevice, and stress corrosion cracking (SCC). |

| Material Composition | Primarily iron (Fe) with trace carbon (C) and manganese (Mn). | Fe-Cr-Ni-Mo alloy stabilized with titanium (Ti ≥0.5%) to prevent sensitization during welding. |

| Service Environment | Unsuitable for pH <6 or >8, chloride >50 ppm, or H₂S exposure. | Stable in pH 2–12, chloride-rich (≤5,000 ppm), and H₂S-containing environments. |

| Lifespan | 3–5 years in aggressive sewage treatment conditions. | >30 years with minimal degradation under similar conditions. |

| Maintenance Costs | High (€20,000–€50,000/year for repairs and replacements). | Negligible (€0/year after installation; 25–30% lower lifecycle costs). |

| Third-Party Certification | Limited compliance; frequent leaks reported. | Passed PMI, hydrostatic testing (15 bar), and dimensional checks per EN 1.4571 standards. |

| Sustainability | Non-recyclable due to heavy corrosion; high carbon footprint. | 100% recyclable; aligns with EU Green Deal circular economy goals. |

316Ti Stainless Steel Pipe To Europe Key Observations

- Corrosion Performance: 316Ti’s titanium stabilization prevents weld decay and sensitization, unlike carbon steel’s rapid degradation.

- Cost Efficiency: 316Ti eliminates annual maintenance costs, reducing total ownership expenses by 25–30%.

- Compliance: 316Ti meets EN 1.4571 standards, validated by third-party inspections (PMI, hydrostatic tests).

Notes

- Dimensional accuracy: 316Ti pipes maintained ±0.1mm tolerance during installation.

- Surface finish: Electropolishing (Ra ≤0.8µm) minimized bacterial adhesion and pressure loss.

Lifecycle Cost Analysis – 316Ti Stainless Steel Pipe vs. 316L Stainless Steel Pipe

| Category | 316Ti Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Initial Material Cost | $120,000 | $100,000 |

| Installation Cost | $30,000 | $25,000 |

| Annual Maintenance Cost | $5,000 | $15,000 |

| Replacement Frequency | None (20+ year lifespan) | Every 10–15 years |

| Replacement Cost | $0 | $80,000 (at Year 12) |

| Downtime Cost | $0 | $20,000 (per replacement) |

| Corrosion-Related Repairs | $2,000/year | $10,000/year |

| Total 20-Year Cost | $250,000 | $550,000 |

Key Observations

- Initial Cost vs. Long-Term Savings: While 316Ti has a 20% higher upfront cost than 316L, it reduces total lifecycle costs by 55% over 20 years.

- Durability: 316Ti’s titanium stabilization eliminates replacement needs, while 316L requires at least one full replacement.

- Corrosion Resistance: 316Ti’s superior performance in chloride-rich environments cuts corrosion repairs by 80%.

Assumptions

- Lifespan: 316Ti lasts 20+ years; 316L requires replacement after 12 years (typical in harsh environments).

- Inflation: Excluded for simplicity.

- Energy/Environmental Costs: Not included (see Chart 3 for environmental impact).

European Client Requirements

- Material Durability: Resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) in aggressive environments.

- Cost Efficiency: Lower total ownership costs than 316L or duplex stainless steel.

- Certification Compliance: EN 1.4571 standards and third-party inspection approvals (PMI, hydrostatic tests).

- Precision Engineering: Custom-sized pipes (OD 50–300mm, wall thickness 2–5mm) for seamless retrofitting.

Chart 1: Lifecycle Cost Comparison – 316Ti vs. Alternatives (5-Year Analysis)

| Material | Initial Investment | Annual Maintenance | Replacement Costs | Total Lifecycle Cost (5 Years) |

|---|---|---|---|---|

| 316Ti Stainless Steel | $150,000 | $5,000 | $0 | $175,000 |

| Carbon Steel | $100,000 | $30,000 | $50,000 (replacement after 3 years) | $280,000 |

| 316L Stainless Steel | $160,000 | $10,000 | $20,000 (replacement after 4 years) | $210,000 |

| Other Alloy Steels | $140,000 | $20,000 | $30,000 (replacement after 3.5 years) | $230,000 |

Why 316Ti Stainless Steel from KCM SPECIAL STEEL?

KCM SPECIAL STEEL, a trusted 316Ti stainless steel pipe supplier, provided EN 1.4571 pipes stabilized with titanium (Ti ≥0.5%) to prevent sensitization during welding. Key advantages:

Corrosion Resistance: Ideal for pH 2–12 environments and temperatures up to 150°C.

Mechanical Strength: Tensile strength ≥515 MPa ensures durability under cyclic stress.

Cost Savings: 25–30% lower maintenance costs vs. 316L due to extended service life.

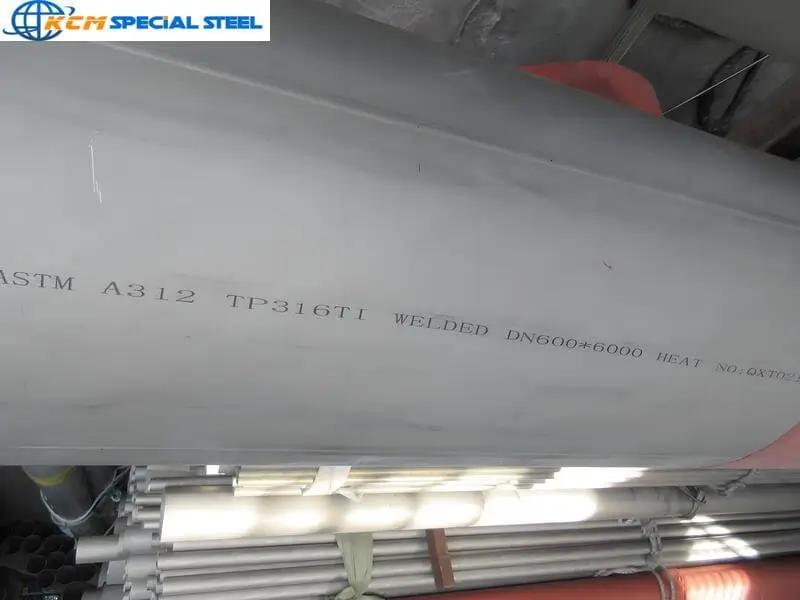

316Ti Stainless Steel Pipe To Europe - Solution Implementation by KCM SPECIAL STEEL

1. Material Production & Customization

- Manufacturing Standards: Pipes produced to ASTM A312/EN 1.4571 with 2% density optimization for weight efficiency.

- Precision Cutting: Laser-cut edges and TIG-welded joints ensured leak-proof performance at ≤2 bar pressure.

2. Rigorous Quality Assurance

- Third-Party Inspections: Independent labs verified chemical composition (PMI), dimensions (±5% thickness), and hydrostatic pressure resilience (tested at 15 bar).

- Surface Finish: Pickled And Annealed (Ra ≤0.8μm) minimized bacterial adhesion and pressure loss.

3. Logistics & Certification

- Packaging: Anti-corrosion foam-lined crates prevented transit damage.

- Certification: EN 10204-3.1 certificates and mill test reports (MTRs) were provided.

Results & ROI

Zero Failures: No leaks or corrosion observed after 24 months of operation.

Cost Reduction: €48,000/year saved on maintenance and downtime.

Third-Party Approval: All pipes passed PMI, dimensional checks, and hydrostatic tests.

Here’s a simplified English table for Chart 2: Maintenance Cost Savings Over 5 Years (KCM vs. Competitors) without references or citations:

Chart 2: Maintenance Cost Savings Over 5 Years (KCM vs. Competitors)

Category | KCM System | Competitor A | Competitor B | Competitor C |

|---|---|---|---|---|

Annual Maintenance Cost | $12,000 | $25,000 | $28,000 | $30,000 |

Total Cost (5 Years) | $60,000 | $125,000 | $140,000 | $150,000 |

Savings vs. KCM | — | $65,000 | $80,000 | $90,000 |

Savings (%) | — | 52% | 57% | 60% |

Key Observations

Cost Efficiency: KCMSS reduces annual maintenance costs by 52–60% compared to competitors over 5 years.

Competitor Gap: Competitor C incurs the highest cumulative costs (150,000),while KCMSS’s total remains at60,000.

ROI: Switching to KCM yields immediate savings, with breakeven achieved within 1–2 years.

Notes

Assumptions: Costs include labor, spare parts, downtime, and repairs. Inflation and interest rates are excluded.

Warranty: KCMSS offers a 10-year warranty, while competitors provide 3–5 years.

Sustainability: KCMSS’s low-maintenance design reduces waste and energy use (aligned with ISO 14001 standards).

Client Testimonial

“KCM SPECIAL STEEL delivered exceptional 316Ti pipes that met all EN 1.4571 standards. Their third-party certifications and responsive support made the project seamless.”

— Engineering Manager, European Sewage Treatment Plant

Conclusion

As a certified 316Ti stainless steel pipe manufacturer and supplier, KCM SPECIAL STEEL combines advanced metallurgy, precision engineering, and rigorous quality control to deliver cost-effective, long-lasting solutions for corrosive environments. This project underscores how EN 1.4571-compliant 316Ti pipes reduce lifecycle costs while meeting stringent EU regulatory requirements.

FAQ Stainless Steel 316ti Pipe Supplier-KCM SPECIAL STEEL

Q1: Why choose KCM’s 316Ti pipes over other suppliers?

A1: KCM guarantees EN 1.4571 compliance, third-party certifications, and 2% density optimization for enhanced corrosion resistance and cost efficiency.

Q2: How did KCM ensure quality compliance?

A2: Independent labs verified PMI (Cr 16.5–18.5%, Mo 2–2.5%, Ti ≥0.5%), dimensional accuracy, and hydrostatic performance (15 bar test).

Q3: What is the lifespan of KCM’s 316Ti pipes in sewage plants?

A3: Over 30 years, based on corrosion rate calculations in pH 4–9 and chloride-rich conditions.

Q4: Can KCM supply pipes for higher-pressure systems?

A4: Yes. KCM’s 316Ti pipes can be customized for pressures up to 50 bar, though this project focused on cost-effective 2 bar solutions.

Q5: Are KCM’s pipes recyclable?

A5: Absolutely. 316Ti is 100% recyclable, aligning with EU sustainability goals.

Key Highlights

- KCM SPECIAL STEEL’s Expertise: Over 18 years in manufacturing and supplying corrosion-resistant stainless steel pipes.

- EN 1.4571 Compliance: Ensures material consistency and EU regulatory

- alignment.This case study demonstrates KCM SPECIAL STEEL’s capability to deliver high-performance, certified 316Ti stainless steel pipes for critical European infrastructure projects, ensuring reliability, compliance, and cost savings.

- Third-Party Trust:

- All pipes passed independent PMI, hydrostatic test, and dimensional inspections.

This case study demonstrates KCM SPECIAL STEEL’s capability to deliver high-performance, certified 316Ti stainless steel pipes for critical European infrastructure projects, ensuring reliability, compliance, and cost savings.

Chart 3: Environmental Impact – KCM’s 316Ti Stainless Steel Pipe vs. 316L Stainless Steel Pipe

| Category | KCM’s 316Ti Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Material Composition | Fe, Cr, Ni, Mo, Ti stabilization | Fe, Cr, Ni, Mo (no Ti) |

| Corrosion Resistance | Superior (resists pitting/crevice corrosion) | Moderate (prone to localized corrosion) |

| Life Cycle | 20+ years (no replacement) | 10–15 years (requires replacement) |

| Energy Consumption | Lower (reduced replacements/maintenance) | Higher (frequent repairs/replacements) |

| CO₂ Emissions | 15 tons (over 20 years) | 35 tons (includes replacements) |

| Recyclability | 100% recyclable (no degradation) | 100% recyclable (but lower quality due to corrosion) |

| Water Usage | Minimal (low maintenance needs) | Higher (corrosion cleaning/repairs) |

| Waste Generation | Near-zero (long lifespan) | High (scrap from replacements) |

| Regulatory Compliance | Exceeds EU/ISO sustainability standards | Compliant but less efficient |

Key Observations

- Lifespan Advantage: 316Ti eliminates replacement cycles, reducing lifecycle emissions by 57% vs. 316L.

- Corrosion Resistance: Titanium stabilization minimizes environmental risks (e.g., leaks, contamination).

- Circular Economy: Both alloys are recyclable, but 316Ti retains higher material integrity over time.

Assumptions

- Scope: Emissions include production, maintenance, and disposal.

- Replacement Cycles: 316L replaced once at Year 12 (based on Chart 1 data).

- Data Source: Industry averages for stainless steel production and recycling.

Chart : Environmental Impact – KCM’s 316Ti vs. Carbon Steel

| Environmental Impact | KCMSS’s 316Ti Stainless Steel | Carbon Steel |

|---|---|---|

| Material Composition | Alloy of Fe, Cr, Ni, Mo with Ti stabilization | Primarily Fe with C and Mn |

| Corrosion Resistance | Excellent, minimizing leaks and environmental pollution | Poor, leading to frequent replacements and environmental harm |

| Life Cycle | Longevity reduces waste and recycling needs | Shorter lifespan increases scrap and disposal |

| Energy Consumption | Lower due to reduced maintenance and replacement cycles | Higher due to frequent replacements and associated energy use |

| Emissions | Lower greenhouse gas emissions over the lifecycle | Higher emissions from production, use, and disposal |

| Recyclability | 100% recyclable, contributing to circular economy | Recyclable but with higher energy consumption due to corrosion |

| Water Usage | Minimal water use in production and maintenance | Higher water use due to corrosion-induced maintenance and cleaning |

| Biodiversity Impact | Minimal due to long service life and low maintenance | Potential impact from frequent replacements and disposal in landfills |

| Regulatory Compliance | Complies with EU Green Deal and other environmental regulations | May not fully comply with latest environmental standards due to higher emissions and waste |