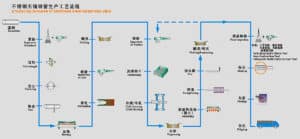

The manufacturing process of stainless steel seamless pipes involves multiple critical stages to ensure structural integrity and performance in applications such as fluid transport23 or heat exchangers3. Below is a concise workflow description:

Raw Material Preparation

High-grade stainless steel alloys (e.g., 304, 316L) are melted in an electric arc furnace, combining iron ore, chromium, nickel, and other trace elements for corrosion resistance1. The molten steel is cast into cylindrical billets.

Piercing and Hot Rolling

The billet is heated and pierced using a rotary piercing mill to form a hollow shell. Subsequent hot rolling elongates the shell into a rough pipe shape, enhancing grain structure uniformity.

Cold Drawing/Cold Rolling

For precise dimensional control, the pipe undergoes cold drawing or cold rolling. This reduces wall thickness and improves surface finish while maintaining mechanical properties.

Heat Treatment

Annealing or solution treatment is performed to relieve internal stresses and restore corrosion resistance. Common methods include bright annealing under inert gas.

Finishing and Testing

Surface Treatment: Pickling or passivation removes oxide layers and enhances surface quality.

Dimensional Inspection: Laser gauges verify outer diameter, wall thickness, and straightness.

Non-Destructive Testing (NDT): Ultrasonic or hydrostatic tests detect internal flaws.

Certification and Packaging

Pipes are marked with material grades (e.g., St 37.4, E235+N)4 and compliance certifications (e.g., DIN 1630, ASTM A312)45. Final packaging ensures protection during transportation.

This streamlined process ensures seamless pipes meet stringent standards for industrial fluid systems23 and high-temperature environments.